What Are Engineering Ceramics?

Engineering ceramics, also known as advanced ceramics, precision ceramics, Technical ceramics, etc., refer to the use of high-purity, ultra-fine synthetic or selected inorganic compounds as raw materials, with excellent mechanical, sound, light, thermal, electrical, biological and other characteristics Ceramics. Engineering ceramics are different from traditional ceramics in terms of raw materials and processes. The specific fine structure makes them have a series of advantages such as high strength, high hardness, wear resistance, corrosion resistance, high temperature resistance, insulation, superconductivity, and biocompatibility, and are widely used In the fields of national defense, chemical industry, metallurgy, electronics, machinery, aviation, aerospace, biomedicine, etc.

Engineering Ceramics And Its Types

Engineering ceramics can be divided into two categories according to their characteristics and uses: structural ceramics and functional ceramics. Structural ceramics refers to ceramics that can be used as engineering structural materials. It has high strength, high hardness, high elastic modulus, high temperature resistance, wear resistance, thermal shock resistance, etc.; functional ceramics refers to electronic, superconducting, magnetic , Optical, energy storage, biological and other characteristics of ceramics.

Engineering Ceramic Materials

Engineering ceramics can be divided into oxide ceramics, nitride ceramics, carbide ceramics, boride ceramics, silicide ceramics, fluoride ceramics, and sulfide ceramics according to their chemical composition.

Below, we introduce several common engineering ceramics!

Alumina, also known as Aluminum Oxide, is a hard wearing advanced precision ceramic material frequently used in a wide variety of industrial applications. Once fired and sintered, it can only be machined using diamond-grinding methods. It features high hardness and wear resistance, low erosion levels, high temperature resistance, corrosion resistance, and bioinertness. Additionally, it can be highly polished making it useful for precision sealing applications like pumps and pistons.

Unlike traditional ceramics that tend to be hard and brittle, Zirconia offers high strength, wear resistance, and flexibility far beyond those of most other technical ceramics. Zirconia is a very strong technical ceramic with excellent properties in hardness, fracture toughness, and corrosion resistance; all without the most common property of ceramics – high brittleness.

Silicon Nitride has the most versatile combination of mechanical, thermal, and electrical properties of any technical ceramic material. It is a high performance technical ceramic that is extremely hard and has exceptional thermal shock and impact resistance. It surpasses most metals high temperature capabilities and has a superior combination of creep and oxidation resistance.

Aluminum nitride (AlN) has high thermal conductivity and electrical insulation, which makes it can be used in various electronic equipment. The aluminum nitride thermal conductivity is 170W / (m.k), which is 5-8 times higher than that of alumina ceramics. Therefore, AlN Ceramics have good thermal shock resistance and can be used in extremely hot environment at 1200 ℃.

Boron nitride crystal belongs to the hexagonal system, the structure is similar to graphite, and there are many similarities in performance, so it is also called “white graphite”.It has good heat resistance, thermal stability, thermal conductivity, high-temperature dielectric strength, and is an ideal heat dissipation material and high-temperature insulating material.

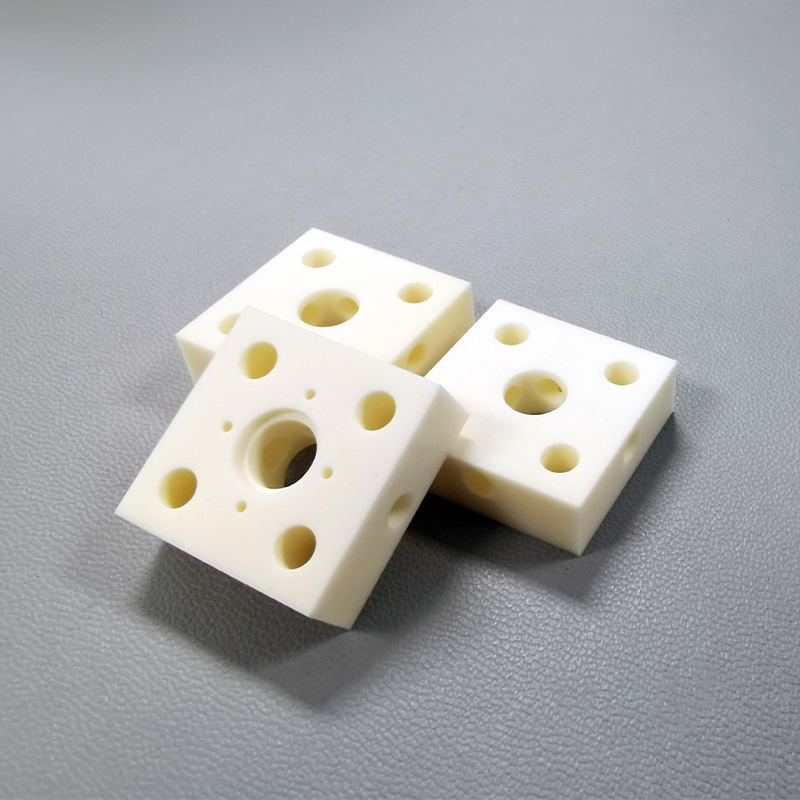

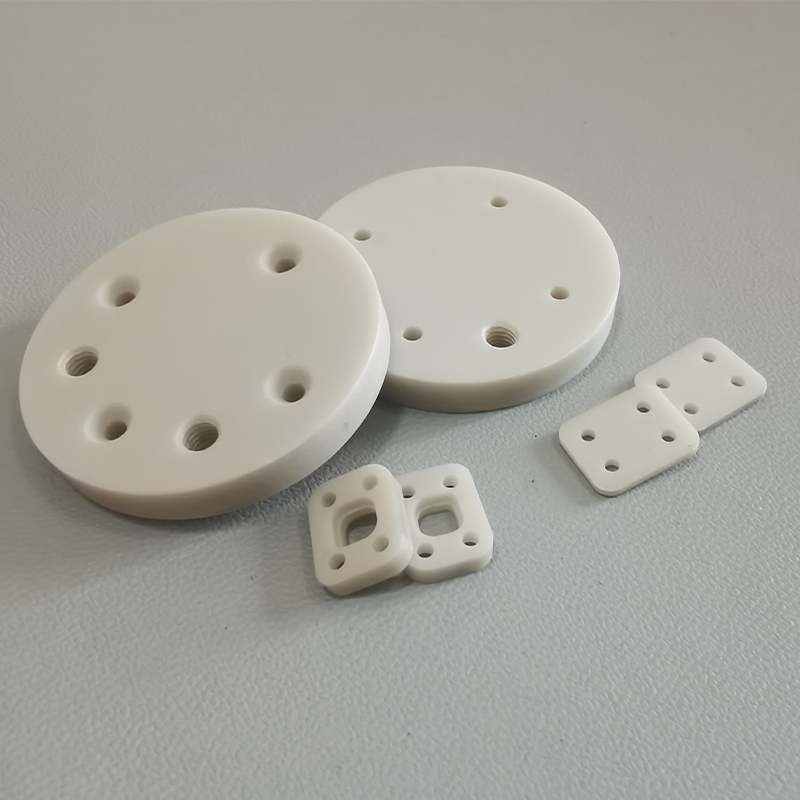

Machinable Glass Ceramic (also known as “Machinable ceramic”) is a polycrystalline composite material, white in its entire body. It is a glass ceramic material with synthetic mica crystallites as the main crystal phase. Machinable ceramic have high mechanical strength, excellent dielectric properties and thermal properties, and good chemical stability.

The special properties of technical ceramic products have produced many applications in electrical engineering, chemical engineering and mechanical engineering. Because technical ceramic products are heat resistant, they can be used for many tasks that are not suitable for materials such as metals and polymers. Technical ceramic materials are used in a wide range of industries, including mining, aerospace, medicine, oil refining, food and chemicals, packaging science, electronics, industry, and transmission power.

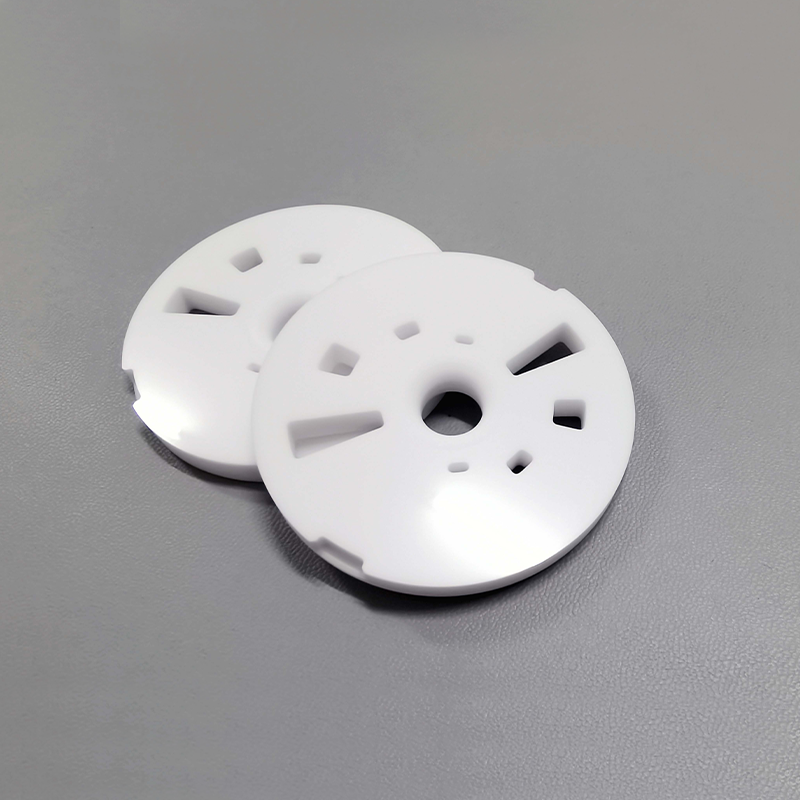

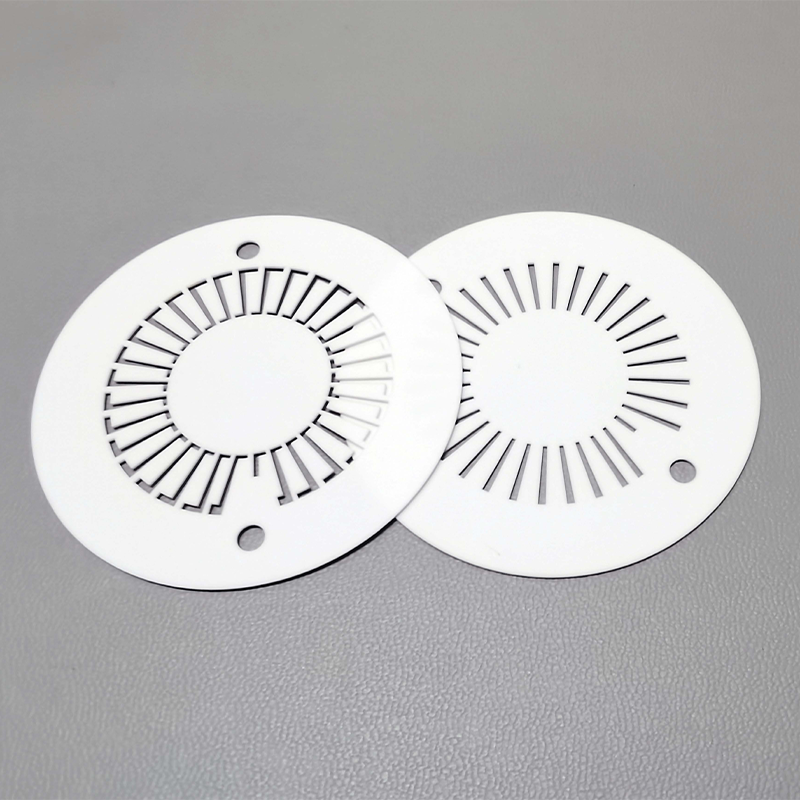

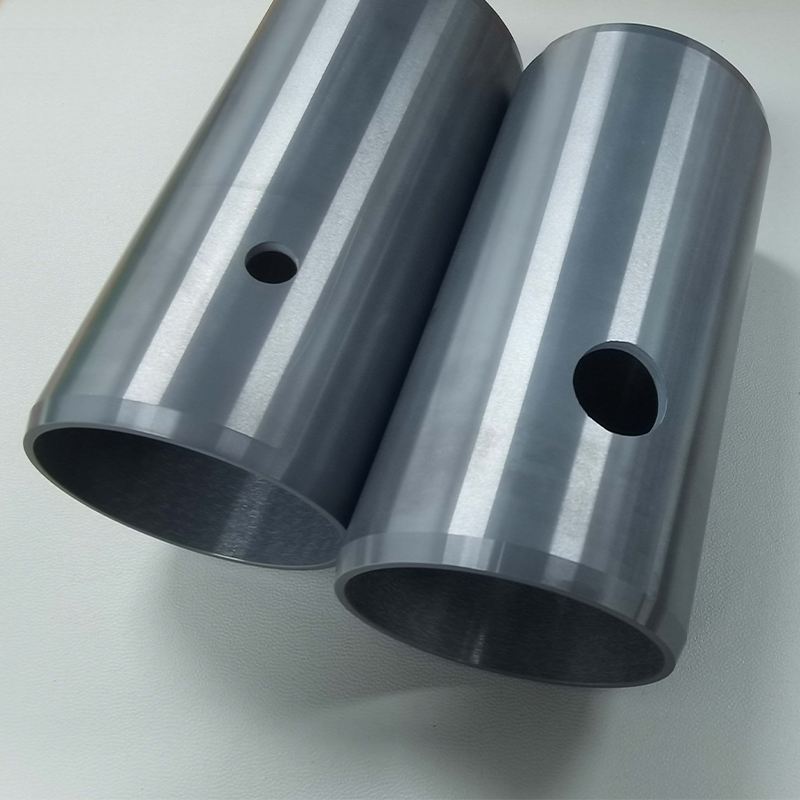

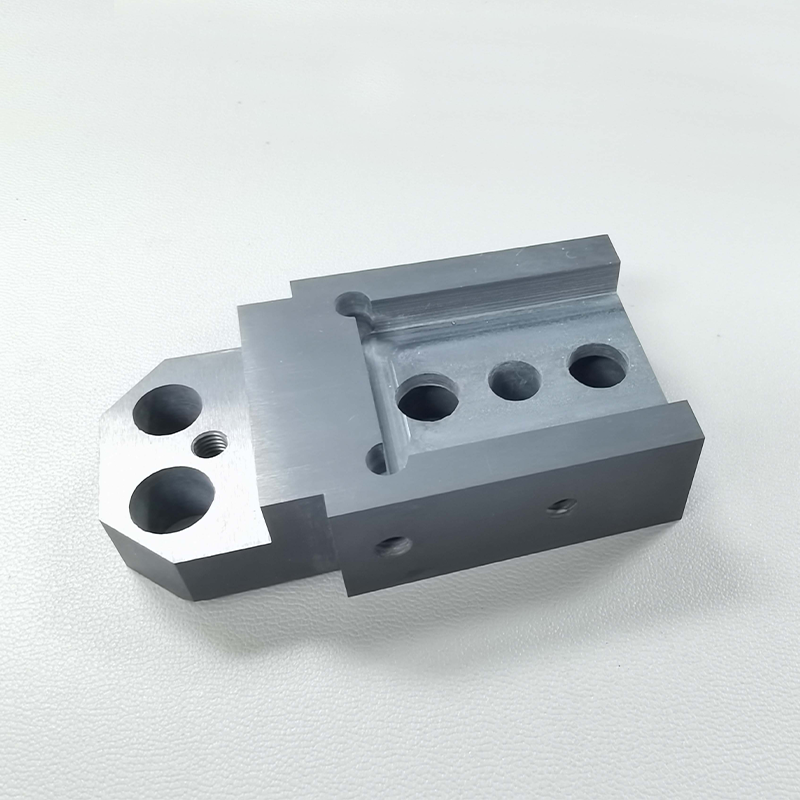

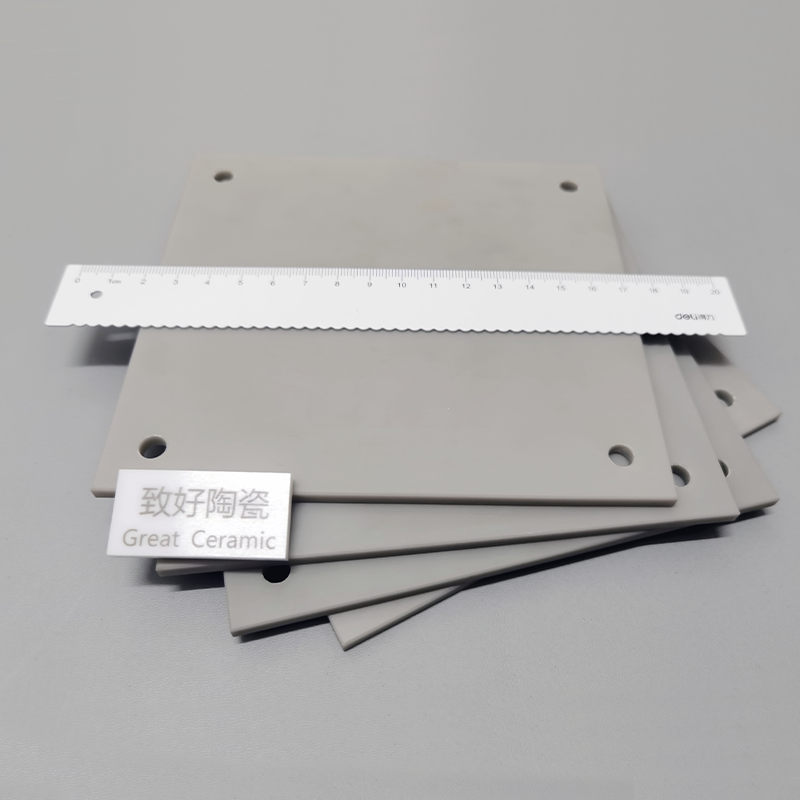

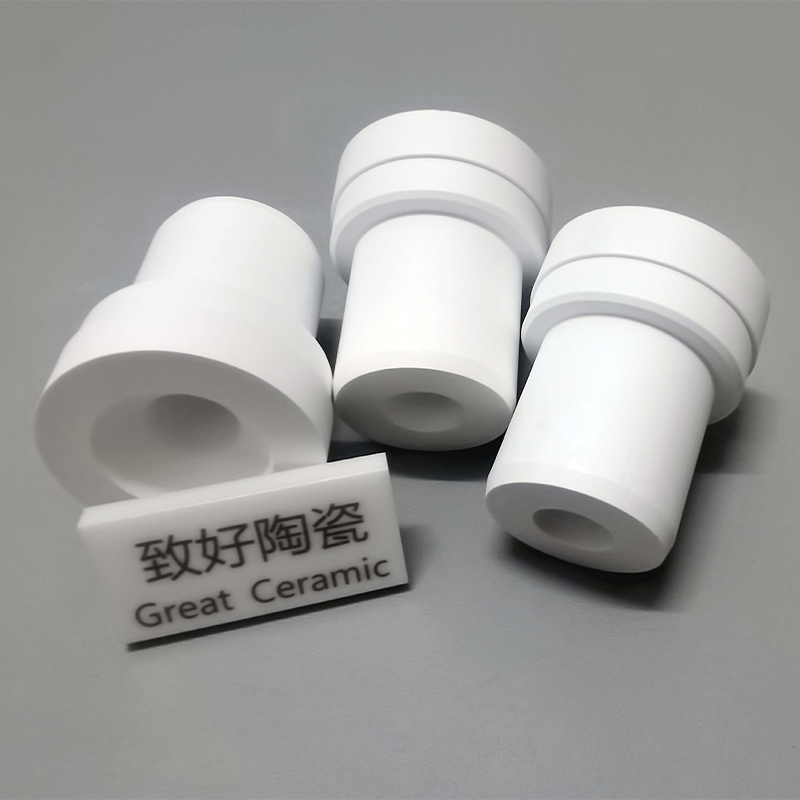

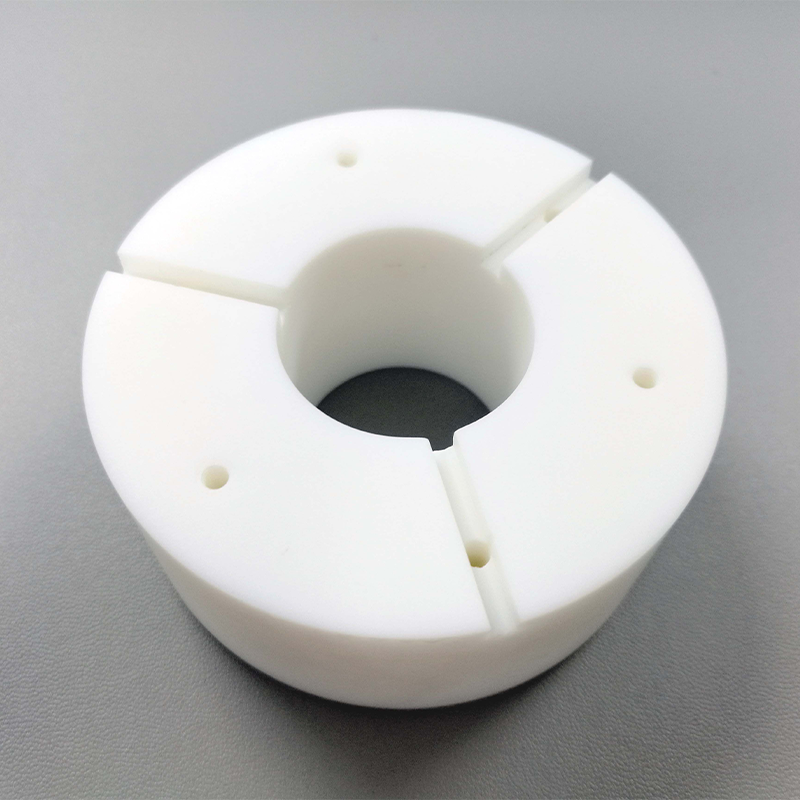

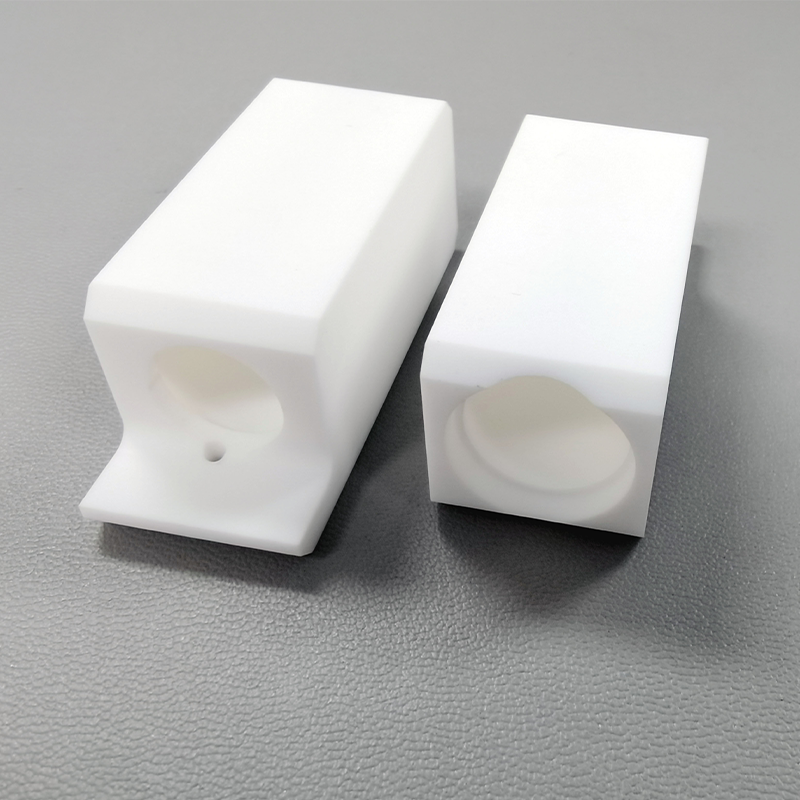

Engineering Ceramics Examples

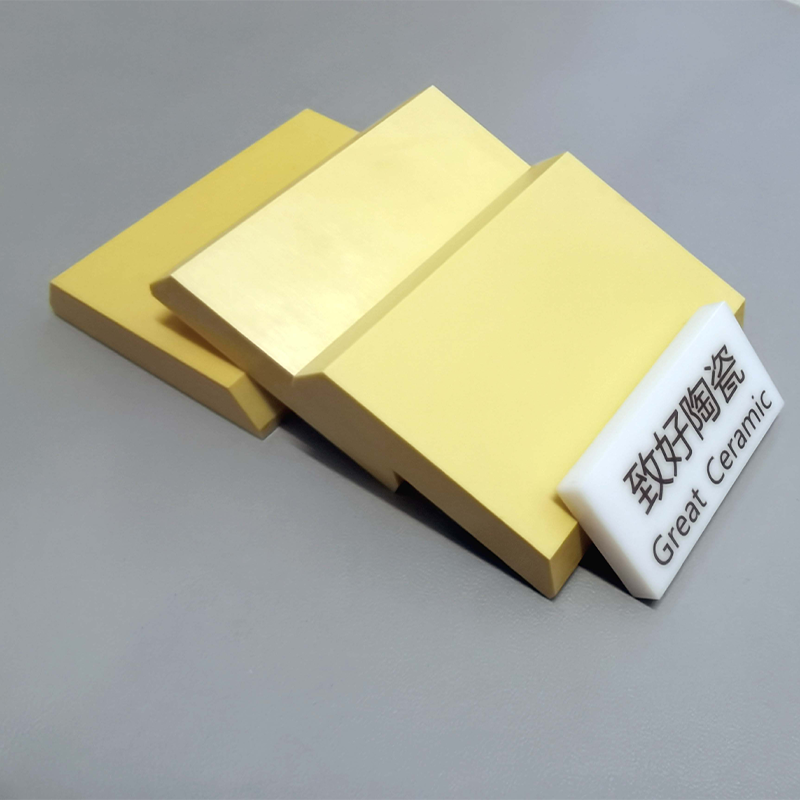

Engineering ceramics are difficult to process because of their high hardness and brittleness. Therefore, custom technical ceramics requires highly professional ceramic engineering knowledge and technical ceramic processing equipment.

Great Ceramic has many years of experience in developing technical ceramic parts. We use our experienced team and in-depth knowledge of technical ceramic materials to create the best technical ceramic application solutions for customers at a competitive price.

Technical Ceramics Companies

Great Ceramic is your Engineering ceramics machining specialist for your precision ceramic prototyping & manufacturing needs; we are always happy to use our many years of advanced ceramics experience to provide advice on materials, design, and application. If you would like to buy Engineering ceramics plates, rods, tubes or custom machined components, please contact us and one of our experts will be happy to assist you.

What is ceramic engineering?

Ceramic engineering is the science and technology of creating objects from inorganic, non-metallic materials. This is done either by the action of heat, or at lower temperatures using precipitation reactions from high-purity chemical solutions. The term includes the purification of raw materials, the study and production of the chemical compounds concerned, their formation into components and the study of their structure, composition and properties.