Advanced Ceramic Machining Expert

Great Ceramic is advanced ceramic machining expert. With many years of ceramic machining experience and highly specialized processing equipment, we provide customers with high-quality precision ceramic parts.

Advanced Ceramic Machining

Due to the extremely high hardness and brittleness of advanced ceramics, ceramic machining has become a difficult task. In order to continuously produce high-quality ceramic parts at a reasonable cost, suitable machining equipment, in-depth material knowledge and correct ceramic manufacturing design are required.

At Great Ceramic, we have a variety of advanced ceramic machining and molding equipment, which can create cost-effective ceramic product solutions for customers.

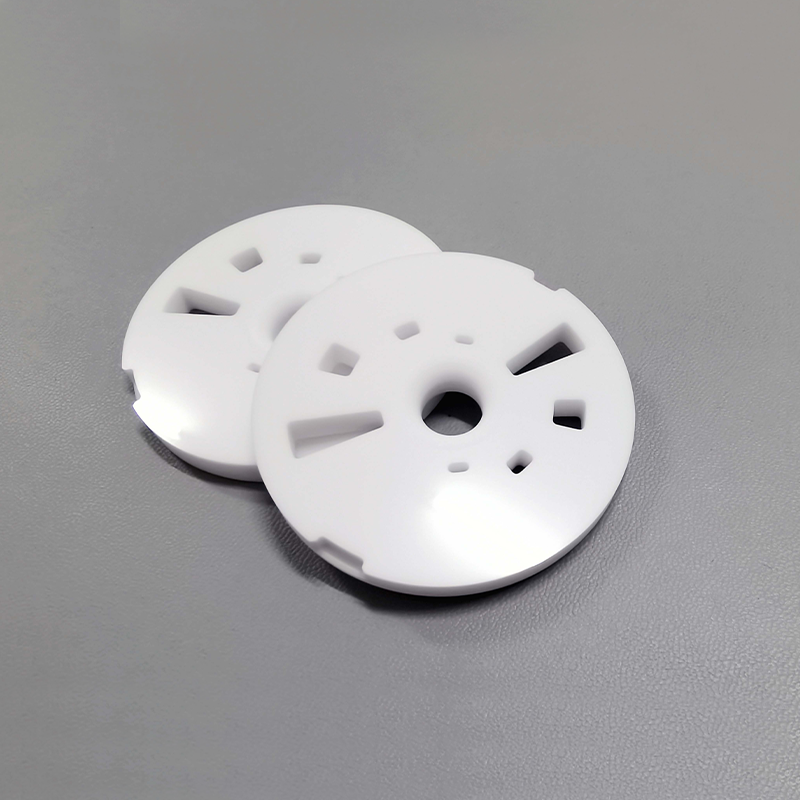

Ceramic CNC Machining

At Great Ceramic, we usually use CNC to process ceramic parts with high dimensional accuracy and complex shapes. For example, holes with high positioning accuracy, irregular edges and curved surfaces, threads, etc.

Compared with traditional metal machining, general ceramic CNC machining can only be ground with diamond abrasive tools. Therefore, the cost of ceramic CNC machining is relatively high.

Ceramics CNC Machining Examples

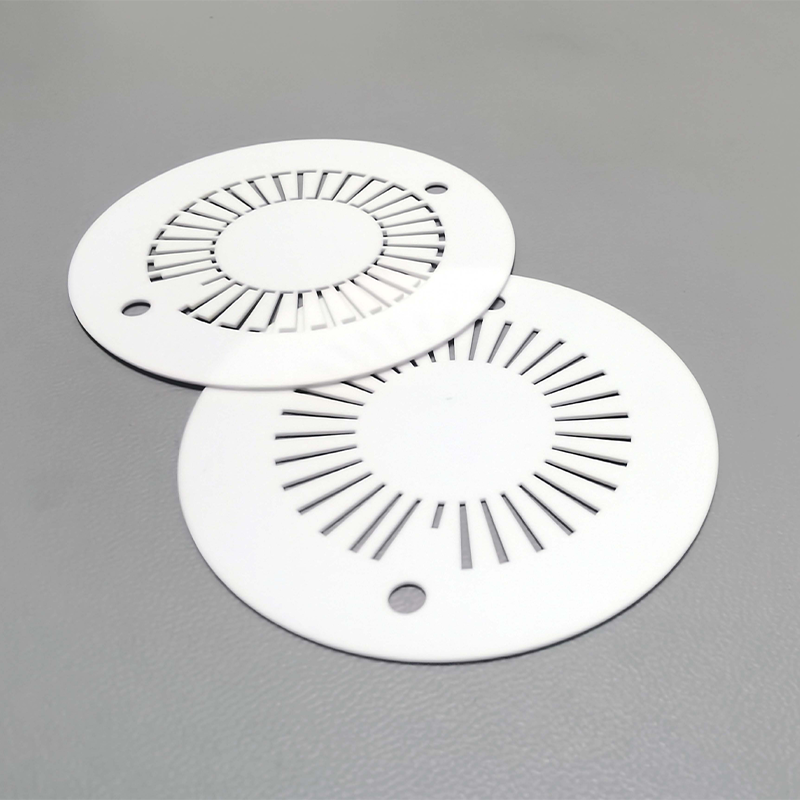

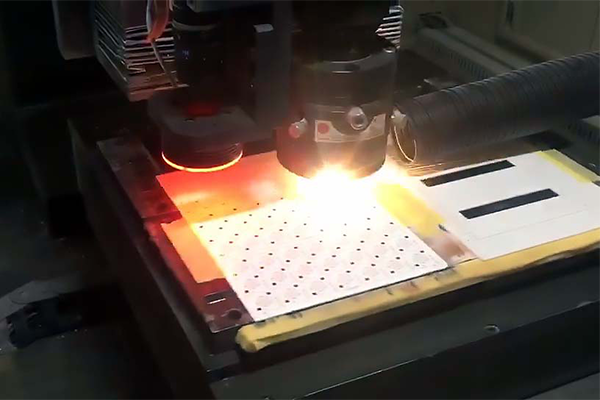

Ceramic Substrate Laser Machining

Ceramic substrate laser machining is a low-cost, high-efficiency ceramic machining method. For many years, Great Ceramic has provided customers with highly customized ceramic laser machining solutions. We can use laser pulse mode to cut ceramic substrates to process complex shapes; we can also use continuous light emission mode to “mark lines” on the ceramic substrate, and finally use it for breaking.

Ceramic Substrate Laser Machining Examples

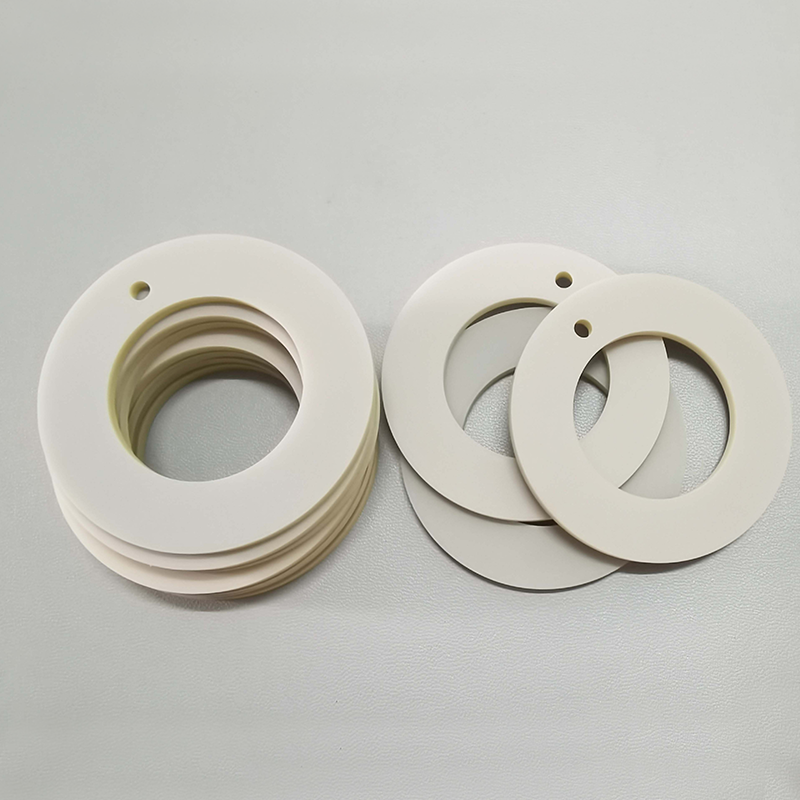

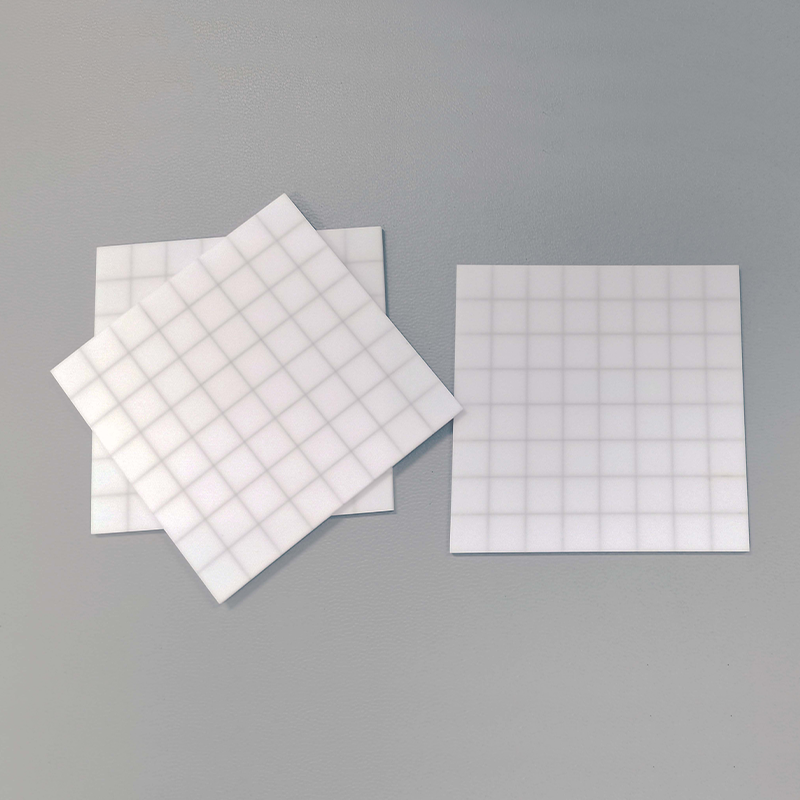

Ceramic Grinding Machining

Generally, advanced ceramic parts will be shaped by grinding. At Great Ceramic, we have a variety of grinding and processing equipment in order to provide customers with highly effective ceramic machining solutions. Our ceramic machining equipment includes surface grinders, centerless grinders, internal grinders, cylindrical grinders, surface polishers, honing machines, etc.

Surface Grinder Ceramic Machining

Surface grinders are usually used to process the plane or step of ceramic parts, and the dimensional accuracy can reach up to ±0.005mm.

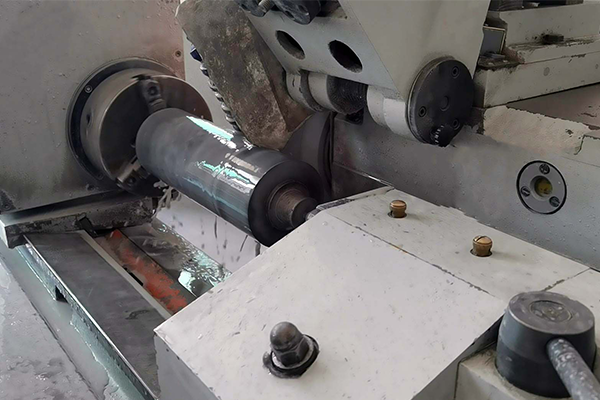

Cylindrical Grinder Ceramic Machining

Cylindrical grinders are used to process various rod and tube ceramic parts, with the highest accuracy up to ±0.005mm.

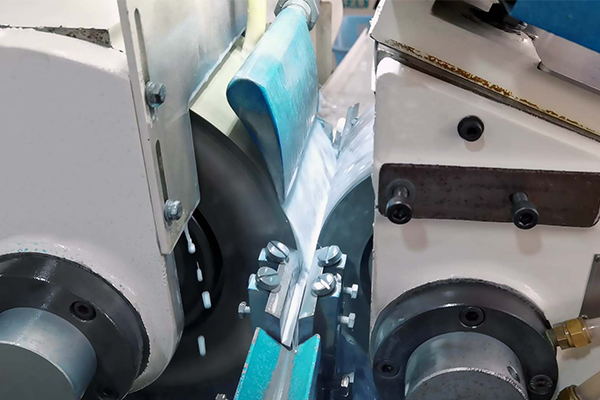

Internal Grinding Machining

The internal grinding machine is used to process the inner holes and steps of ceramic tubes and ceramic sleeves, and has high flexibility.

Centerless Grinding Machining

Using a centerless grinder to process the outer surface of the cylinder can ensure extremely high precision.

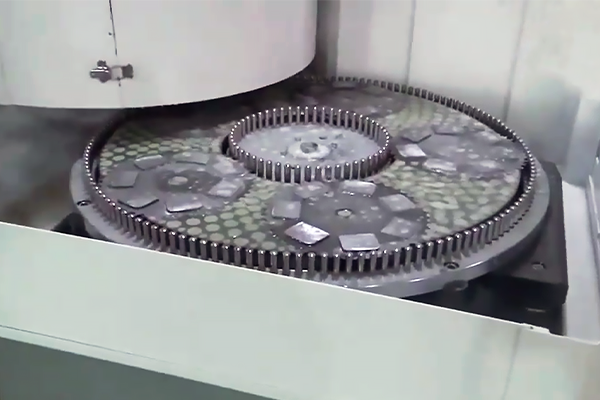

Surface Polishing Machine

The plane polishing machine is used to process the surface of plate-like products, which can obtain high flatness and roughness.

Ceramic Honing

The honing machine is used to polish the inner hole of the ceramic tube, which can obtain high dimensional accuracy and roughness.

Ceramic Machining Tolerances

Under normal circumstances, the dimensional accuracy requirements of advanced ceramic machining will be produced strictly with reference to the technical data and information provided by the customer. For products with dimensional requirements that we cannot meet, unreasonable structural design, and high estimated production costs, we will make reasonable suggestions when responding to customers’ quotations.

All tolerances can be improved according to the size, shape and geometry of advanced ceramic parts. Great Ceramics is committed to ensuring that we only provide the highest quality parts that meet or exceed customer specifications.