Silicon Carbide (SiC)

Silicon carbide material is a technical ceramic with strong covalent bonds, the main component is SiC, which has excellent mechanical properties, excellent oxidation resistance, high wear resistance and low friction coefficient. The biggest advantage of silicon carbide ceramics is that it can maintain high strength and hardness at a high temperature of 1400 degrees Celsius. In addition, the thermal conductivity of Sintered silicon carbide ceramics is also very high, second only to beryllium oxide and aluminum nitride ceramics in technical ceramics. Therefore, SiC ceramics are suitable for use in various severe environments.

Silicon Carbide: Sintering Methods and Models

At present, the sintering methods of silicon carbide ceramics mainly include hot pressing sintering, direct sintering, reaction bonding, recrystallization sintering, microwave sintering and spark plasma sintering. Different sintering methods will cause different differences in the properties of silicon carbide materials. Therefore, the two most common sintering molding methods are briefly introduced below.

Direct Sintered Silicon Carbide(SSiC)

Direct sintered silicon carbide is produced from pure silicon carbide powder and oxide-free sintering aids in an inert atmosphere at high temperatures around 2,000°C using a range of forming methods including dry pressing and extrusion.

Reaction Bonded Silicon Carbide(SiSiC)

The process of preparing silicon carbide by reaction sintering is to premix an appropriate amount of carbon containing material in silicon carbide powder and synthesize new silicon carbide by using high temperature reaction between carbon and residual silicon in silicon carbide powder so as to form silicon carbide ceramics with compact structure.

Reactive sintering process has the advantages of low sintering temperature, short sintering time and near net size forming, etc. It is the most effective method to prepare large size and complex shape silicon carbide ceramics.

Silicon Carbide Properties

- Relatively low density;

- Higher mechanical strength;

- Excellent high temperature strength;

- Oxidation resistance;

- Excellent thermal shock resistance;

- High hardness and wear resistance;

- Low thermal expansion and high thermal conductivity;

- Excellent chemical resistance.

SiC Material Performance Parameters

| Properties | Unit | SSiC | SiSiC | Si3N4 |

|---|---|---|---|---|

| Colour | —— | Dark Gray | Dark Gray | Gray or black |

| Density | g/cm³ | 3.15 | 3.02 | 3.2 |

| Porosity | % | ≤0.1 | ≤0.1 | —— |

| Hardness | GPa | 22 | 22 | 15 |

| Compressive Strength | MPa | 2600 | 2600 | 2500 |

| Flexural Strength | MPa | 400 | 250 | 700 |

| Elastic Modulus | GPa | 410 | 330 | 300 |

| Maximum Use Temperature | ℃ | 1400 | 1000 | 1100 |

| Thermal Conductivity | W/(m・K) | 100~120 | 45(1200℃) | 15~20 |

| Coefficient Of Thermal Expansion | 1 x 10-6/°C | 4 | 4.5 | 3 |

*The values are typical material properties and may vary according to products configuration and manufacturing process. For more details, Please feel free to contact us.

Chemical Properties of Silicon Carbide Materials

When the temperature in the oxygen reaction reaches 1300°C, a protective layer of silicon dioxide will be formed on the surface of the silicon carbide crystal. With the thickening of the protective layer, the internal silicon carbide is resisted and continued to bond, so that the silicon carbide crystalline silicon carbide has good chemical resistance. In terms of corrosion resistance, SiC materials have strong acid resistance due to the role of silicon dioxide protective film, but poor alkali resistance.

Silicon Carbide Uses

Silicon carbide material not only has low density, but also has extremely high hardness, which is one of the hardest ceramic materials. Its material properties can remain unchanged at a temperature of 1400 °C. And the higher Young’s modulus (>400GPa) ensures the dimensional stability under high pressure. It is also toxicologically safe and can also be used in the food industry. In addition, SiC materials have excellent thermal conductivity, low thermal expansion, and are very resistant to acids and alkalis.

- Rotating ball & rollers bearings

- Cutting tools

- Engine components

- valves, rocker arm pads, seal faces

- Induction heating coil supports

- Turbine blades, vanes, buckets

- Welding & brazing jigs

- Heating Element components

- Fixed and mobile turbine components

- Seals, Bearings, Pump Vanes

- Ball valve accessories

- Wear plate

- Kiln furniture

- Heat exchanger

- Semiconductor Wafer Processing Equipment

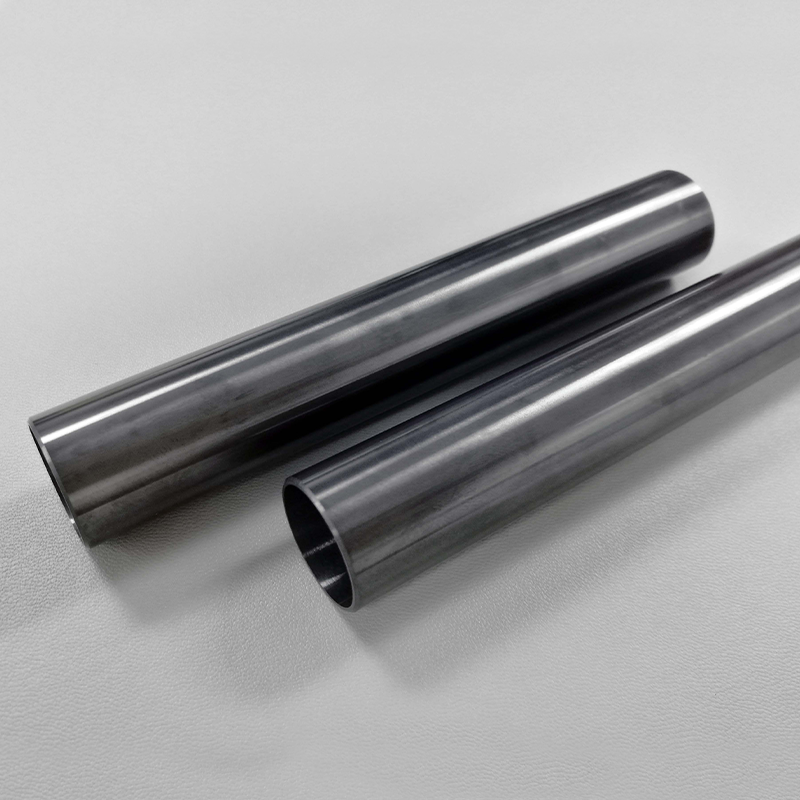

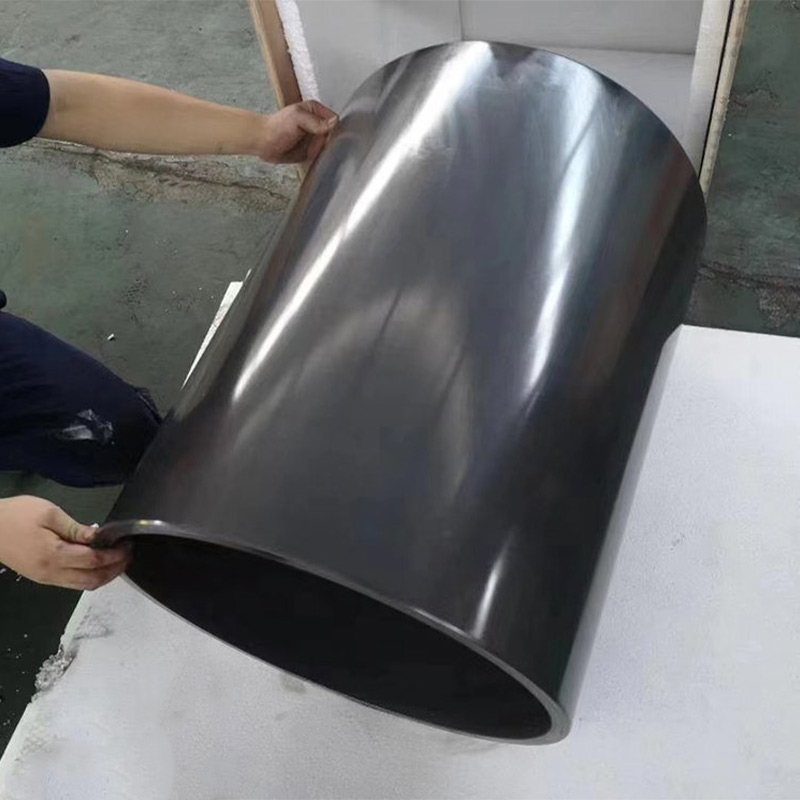

Silicon Carbide Structural Parts

At Great Ceramic, we rely on our rich experience accumulated over the years, a variety of sophisticated processing equipment, and professional knowledge of ceramic materials to provide customers with customized processing services for various silicon carbide structural parts.

Silicon Carbide Ceramics Manufacturers

Great Ceramic is a professional manufacturer of silicon carbide material. We are always happy to use our many years of experience in advanced ceramics to advise on materials, designs and applications. If you would like to purchase silicon carbide sheets, rods, tubes or custom machined structure parts, please contact us and each of our experts will be happy to assist you.