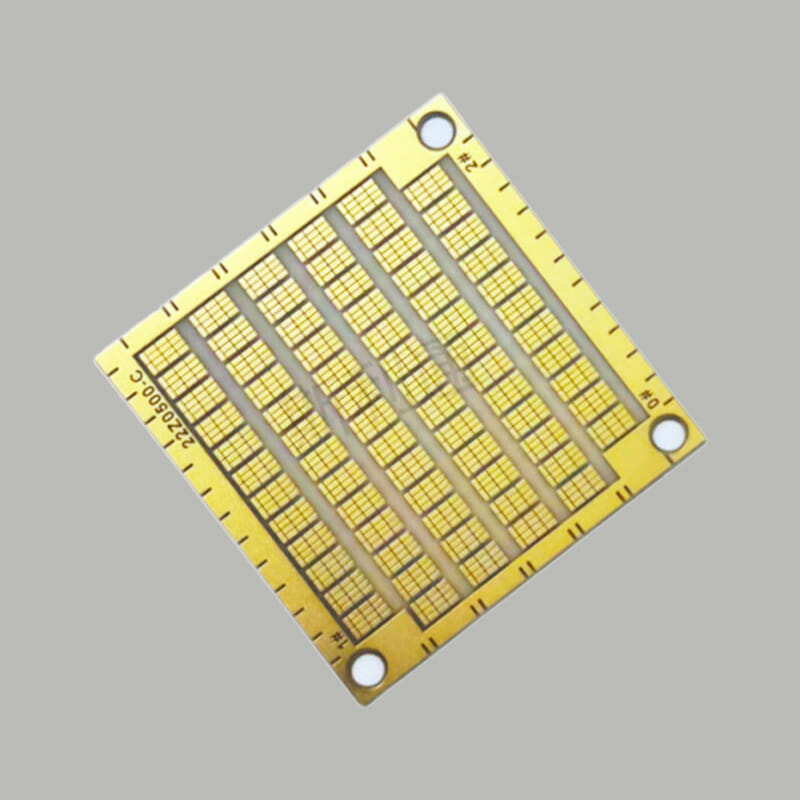

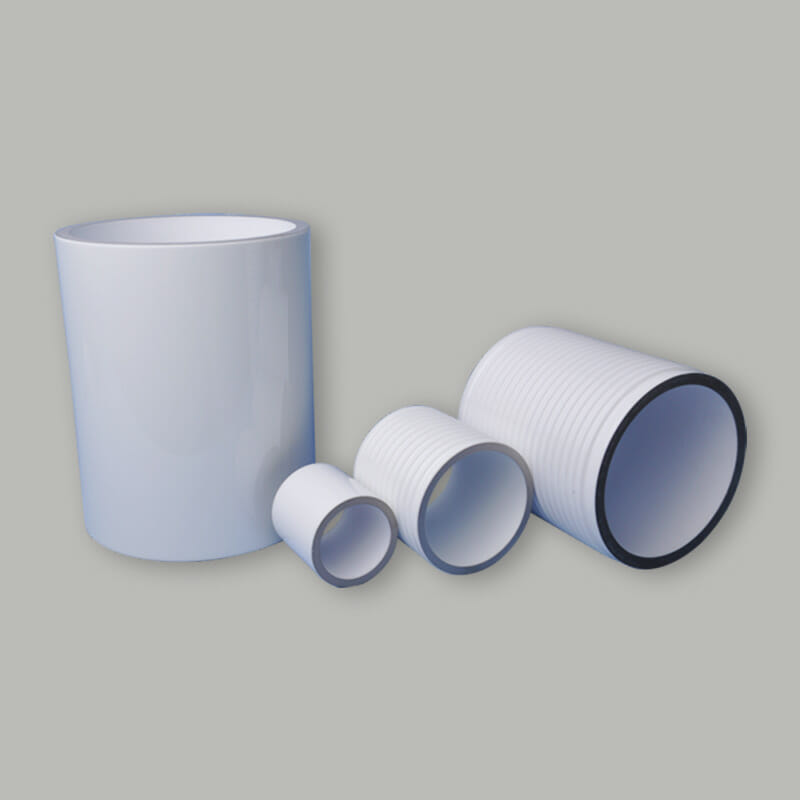

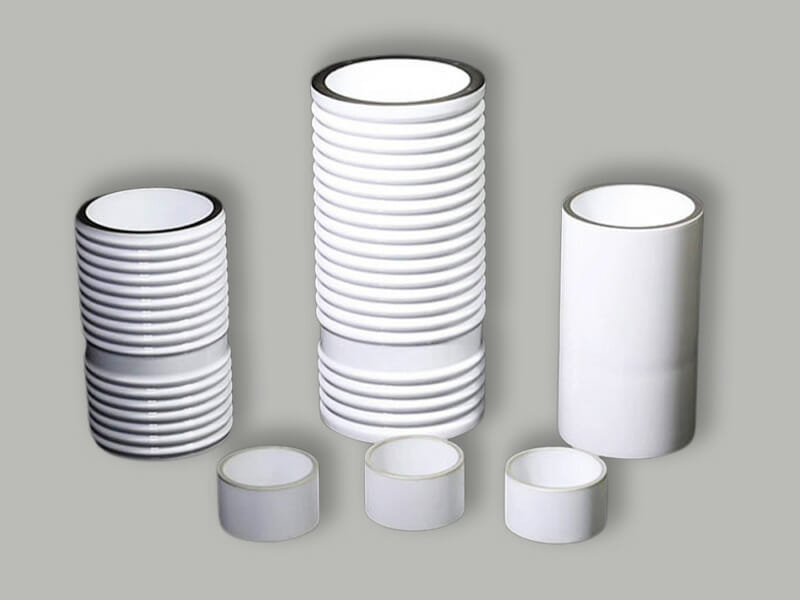

Metallized Ceramic Parts

Metallized ceramic parts are ceramic parts that have a thin layer of metal deposited onto their surface using various techniques such as sputtering, electroplating, or vapor deposition. The metal layer acts as a bonding interface between the ceramic part and the filler metal, allowing for a strong and reliable bond to form during the brazing process.

Ceramic Metallization Company

Metallized ceramic parts supplied by Great Ceramic are used to produce high-performance brazed assemblies for applications such as vacuum interrupters, speed control tubes and microwave tubes in the power electronics industry. In addition, we can customize high-quality metallized ceramic parts according to customer needs.

Ceramic Metals for Brazing

We apply thin metallization layers to ceramic parts like alumina, zirconia, and silicon carbide to promote wetting and bonding with brazing filler metals. Common metallization materials include:

- Nickel – Diffuses well with silver-based braze alloys

- Copper – Excellent wettability but requires plating with gold or nickel

- Kovar or Invar – Alloys match ceramics’ CTEs to minimize residual stress

- Tungsten or Moly-Manganese – Active metal brazes readily bond to these layers

Proper surface preparation ensures strong adhesion of the metallization layer to the ceramic. Our engineering experts work with you to select the best metallization materials and processes to achieve reliable, high-strength brazed joints, even with challenging geometries.

Metallization brings important advantages to ceramic brazing:

- Permits dissimilar material joining with ceramics

- Enables use of filler alloys that only wet to metals

- Reduces brazing voids and cracks

- Provides compliance to relieve residual stresses

- Allows brazing of complex ceramic shapes

Technical Parameters

| Project title | Unit | 96% Al2O3 | 97% Al2O3 | 99% Al2O3 | 99.6% Al2O3 |

| Alumina content | % | Al2O3≧95% | Al2O3≧97% | Al2O3≧99% | Al2O3≧99.6% |

| Size range | mm | 0.5-500 | 0.5-500 | 0.5-500 | 0.5-500 |

| Highest accuracy | mm | 0.01 | 0.01 | 0.01 | 0.01 |

| Bulk density | g/cm3 | ≧3.67 | ≧3.70 | ≧3.85 | ≧3.90 |

| Flexural strength | MPa (25℃) | ≧300 | ≧300 | ≧350 | ≧400 |

| Compressive strength | GPa (25℃) | ≧1.8 | ≧1.8 | ≧2.0 | ≧2.3 |

| Thermal conductivity | W/m.K | 10-20 | 10-20 | 15-21 | 15-21 |

| Average linear expansion coefficient | /℃ (20~500℃) | 7.36×10-6 | 6.9×10-6 | 6.9×10-6 | 6.9×10-6 |

| Dielectric constant | 1MHz (20℃) | 9.1 | 9.5 | 9.8 | 10 |

| Dielectric loss tangent value | 1MHz (20℃) | ≦4×10-4 | ≦3×10-4 | ≦2×10-4 | ≦2×10-4 |

| Volume resistivity | Ω.cm (100℃) | ≧1×1014 | ≧1×1014 | ≧1×1014 | ≧1×1014 |

| DC breakdown strength | KV/mm | ≧30 | ≧35 | ≧25 | ≧25 |

| Thermal shock resistance | ℃ | 20~800 | 20~800 | 20~800 | 20~800 |

| Maximum operating temperature | ℃ | ≦1300 | ≦1400 | ≦1500 | ≦1500 |

| Acid resistance | General | Suitable | First-rate | First-rate | |

| Alkali resistance | General | Suitable | Suitable | First-rate | |

| Ease of metallization | Easy | Normal difficulty | Medium difficulty | Very difficult | |

| Air tightness | Pa•m3/s | ≦1×10-11 | ≦1×10-11 | ≦1×10-10 | ≦1×10-9 |

| Average Tension strength | MPa | 130 | 130 | 130 | 130 |

Note: Each batch may be different, for reference only.

Note: Please view it on your computer.

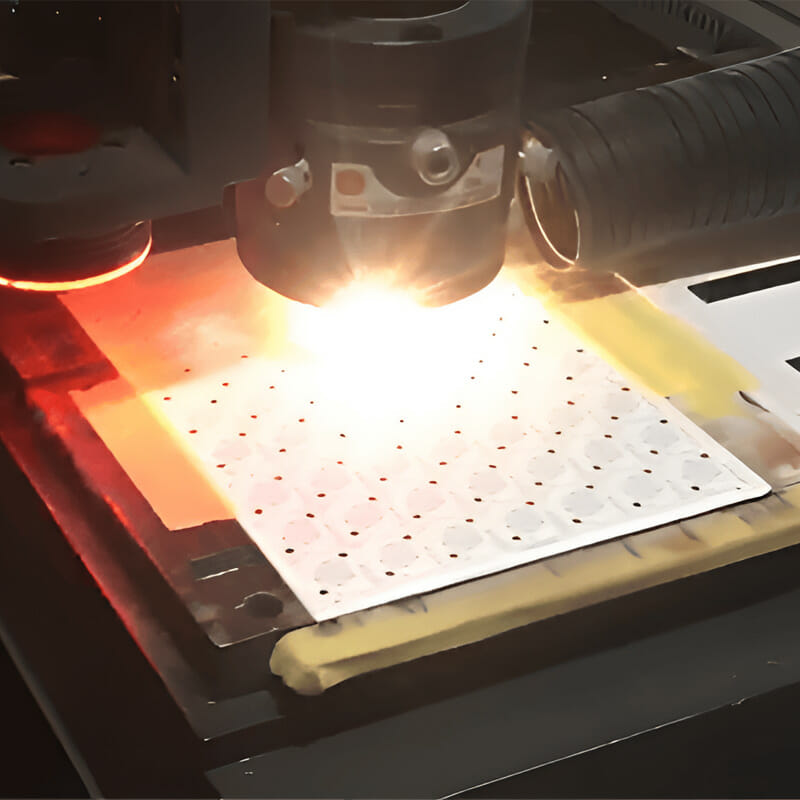

Learn about laser processing of ceramic substrates

Learn about ceramic substrate metallization