Boron Nitride(BN) Ceramics

Boron nitride crystal belongs to the hexagonal system, the structure is similar to graphite, and there are many similarities in performance, so it is also called “white graphite”.

It has good heat resistance, thermal stability, thermal conductivity, high-temperature dielectric strength, and is an ideal heat dissipation material and high-temperature insulating material. Boron nitride has good chemical stability and can resist most of the erosion of molten metal. It also has good self-lubricating properties. Boron nitride products have low hardness and can be machined with an accuracy of 1/100mm.

The composition of BN ceramics

BN is a crystal composed of nitrogen atoms and boron atoms. The chemical composition is 43.6% boron and 56.4% nitrogen, with four different variants: hexagonal boron nitride (HBN), rhombohedral boron nitride (RBN), cubic boron nitride (CBN) and wurtzite nitrogen Boron (WBN).

Available Grades of BN Ceramics

- Pyrolytic Boron Nitride(PBN):Purity is greater than 99.99%

- Hexagonal Boron Nitride(HBN): BN(>99%)+ Boric Oxide(B2O3)

- Composite Boron Nitride Ceramics

Mechanical Properties

| Properties | Unit | HBN | PBN | Composite BN |

|---|---|---|---|---|

| Main Ingredients | % | BN>99% | BN>99.99% | Many kinds |

| Adhesive | —— | B2O3 | No | Multiple types |

| Colour | —— | White | White | Grey |

| Density | g/cm³ | 2.0 | 2.0~2.2 | 2.3~2.9 |

| Hardness(Knoop) | MPa | 39 | 692 | >100 |

| Compressive Strength | MPa | 100 | 173 | 280 |

| Flexural Strength | MPa | 30 | 150 | >100 |

Thermal Properties

| Properties | Unit | HBN | PBN | Composite BN |

|---|---|---|---|---|

| Maximum Use Temperature | ℃ (in oxidizing atmosphere) | 850 | 1000 | 1000 |

| Maximum Use Temperature | ℃ (in an inert atmosphere) | 2200 | 3000 | 2000 |

| Maximum Use Temperature | ℃ (under vacuum environment) | 1800 | 2300 | —— |

| Thermal Conductivity @ 25°C | W/(M・K) | >30 | 60 | 35 |

| Thermal Expansion at 25–1000°C | 10-6/℃ | >1.8 | —— | 2 |

| Specific Heat | J/g·℃ | 0.81 | 0.90 | —— |

Electrical Properties

| Properties | Unit | HBN | PBN | Composite BN |

|---|---|---|---|---|

| Dielectric Constant | 1MHz | 4.0 | 3.0 | —— |

| Dielectric Strength | kV/mm | 79 | 56 | 9.0 |

| Volume Resistivity @ 25°C | Ω・cm | >1013 | >1014 | >1013 |

*The values are typical material properties and may vary according to products configuration and manufacturing process. For more details, Please feel free to contact us.

What can Boron Nitride Ceramics be used for?

- Fracture ring for continuous casting of metal

- Heat treatment fixture

- High temperature lubricant

- Release agent

- Molten metal and glass castings

- Nozzle for transfer or atomization

- Laser nozzle

- Ion thruster discharge channel

- Nuclear shield

- Induction heating coil bracket

- Gasket

- High temperature and high voltage electric insulator

- Furnace support requiring resistivity

- Crucible and container for high purity molten metal

The Advantages Of Hexagonal BN Ceramics:

- High heat resistance: sublimation at 3000°C; at 1800°C, its strength is twice that at room temperature. It will not break when cooled from 1500°C to room temperature dozens of times; it will not become soft in an inert gas at 2800°C.

- High conductivity: The hot-pressed product is 33W/MK, the same as pure iron. When it is higher than 530℃, it has the maximum thermal conductivity above 530℃.

- Low thermal expansion coefficient: Its thermal expansion coefficient is 2×10-6, second only to quartz glass, and the lowest among ceramics. Due to its high thermal conductivity, it has high thermal shock resistance.

- Excellent electrical properties: excellent high-temperature insulation; up to 1014Ω-cm at 25°C and 103Ω-cm at 2000°C. So it is the best high temperature. Insulating material in ceramics. When the breakdown voltage is 3KV/MV, the low dielectric loss is 108HZ, it can reach 2.5×10-4, the dielectric constant is 4, and it can penetrate microwave and infrared rays.

- Extremely strong corrosion resistance: Will not react with common metals (iron, copper, aluminum, lead, etc.), rare earth metals, precious metals, semiconductor materials (germanium, silicon, potassium arsenide), glass, molten salt (crystal) , Fluoride and slag), inorganic acids and alkalis.

- Low friction coefficient: U is 0.16, which will not increase at high temperature. It has higher temperature resistance than molybdenum disulfide and graphite. The oxidizing atmosphere is 900°C; it can be used at 2000°C under vacuum.

- High purity and high boron content: the impurity content is less than 10PPM, and the boron content exceeds 43.6%.

- Machinability: Its hardness is Mohs 2, so it can be processed into high-precision parts and components by conventional machining.

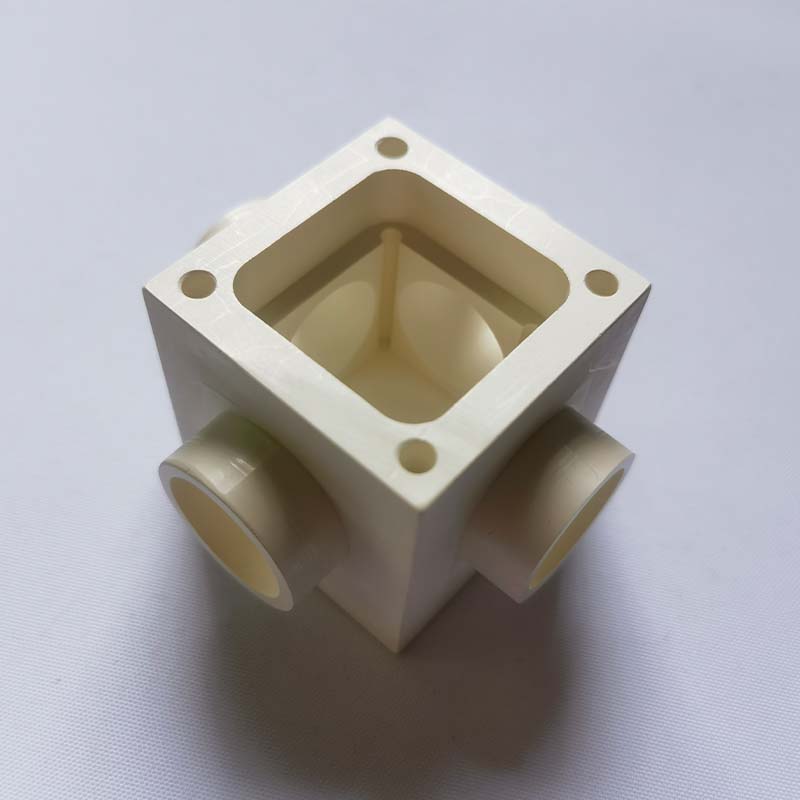

Our Boron Nitride Ceramic Service

Great Ceramic is an expert in the production of technical ceramics. Since 2013, we have participated in and provided more than 3,000 types of precision ceramic products to hundreds of companies.

We can provide you with ceramic processing, ceramic raw materials, ceramic mold forming, surface metallization and other services, and we are committed to providing only products and services that meet or exceed customer quality requirements.

Machining

Materials