Beryllium Oxide(BeO) Ceramics

Beryllium oxide ceramics are ceramics with beryllium oxide (BeO) as the main component. Mainly used as materials for large-scale integrated circuit substrates, high-power gas laser tubes, heat sink shells of transistors, microwave output windows and neutron moderators.

The melting point of beryllium oxide is 2530-2570°C and the theoretical density is 3.02g/cm3. It can be used for a long time under 1800°C vacuum, 2000°C inert atmosphere, 1800°C oxidizing atmosphere. The most outstanding performance of beryllium oxide ceramics is its large thermal conductivity, which is similar to metal aluminum and 6-10 times that of aluminum oxide. It is a dielectric material with unique electrical, thermal and mechanical properties.

Our Beryllium Oxide Services:

Great Ceramic is an expert in the production of technical ceramics. Since 2013, we have participated in and provided more than 3,000 types of precision ceramic products to hundreds of companies.

We can provide you with ceramic processing, ceramic raw materials, surface metallization and other services. We are committed to only providing products and services that meet or exceed customer quality requirements.

Machining

Materials

Metallization

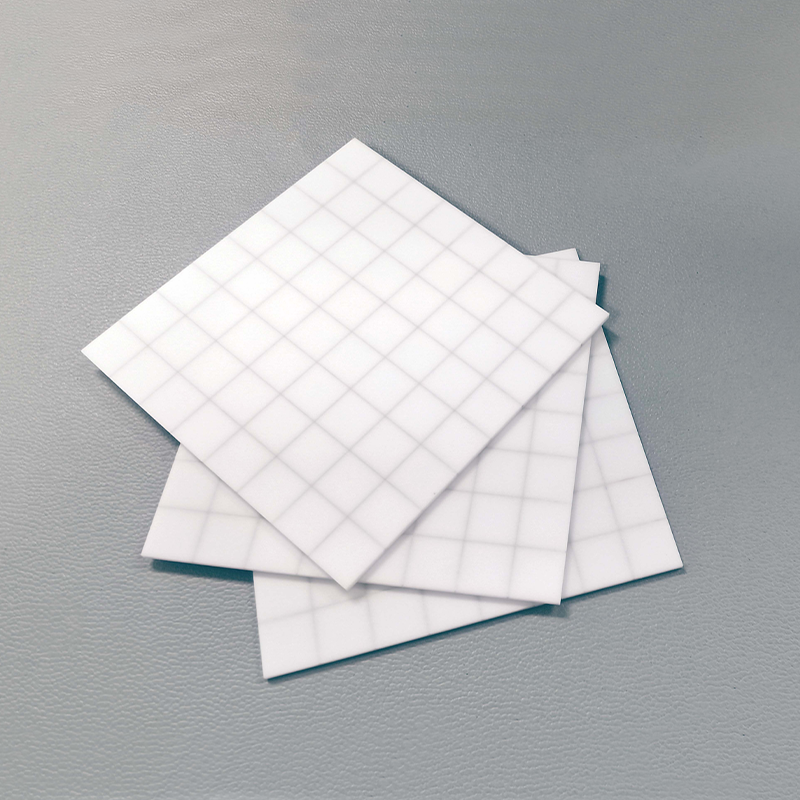

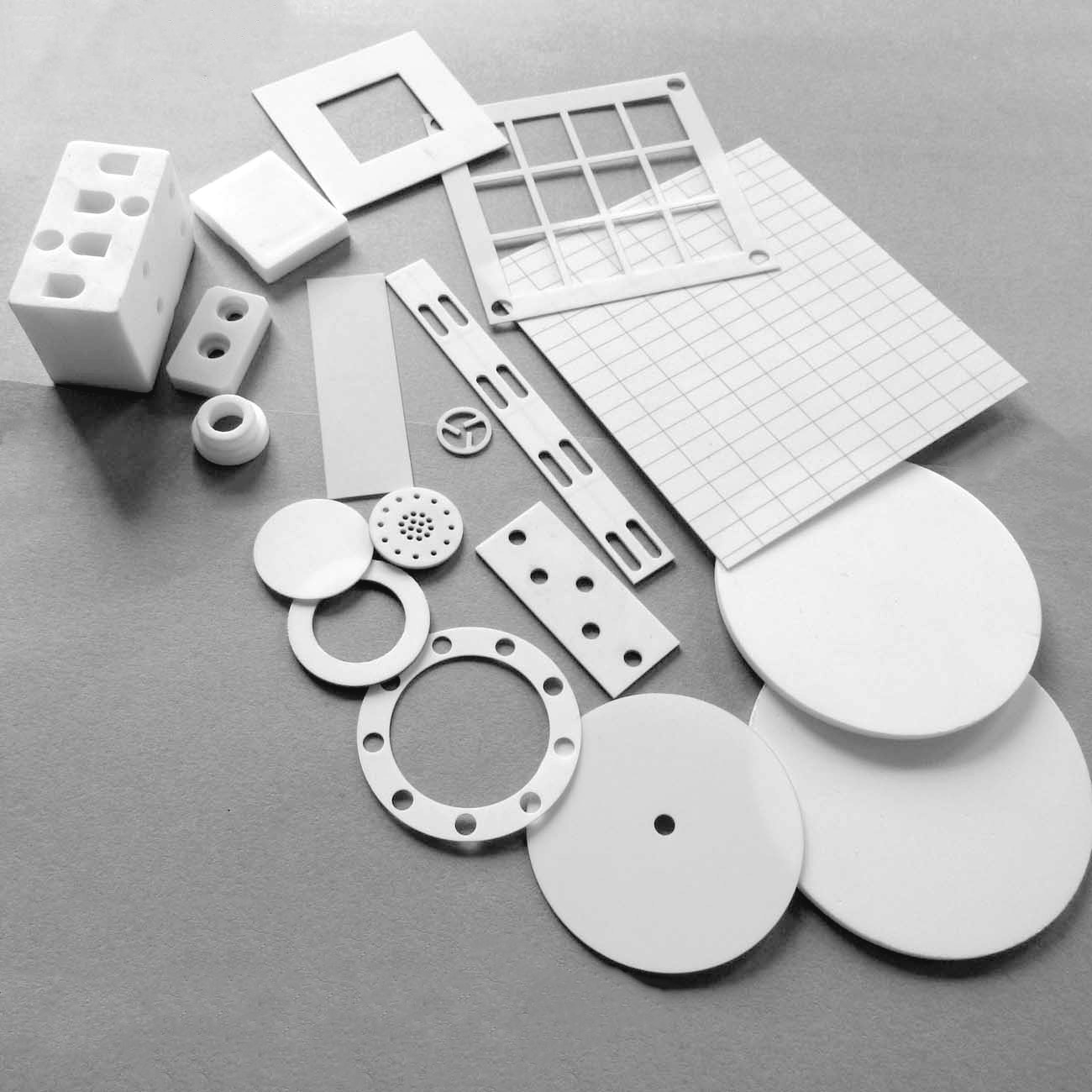

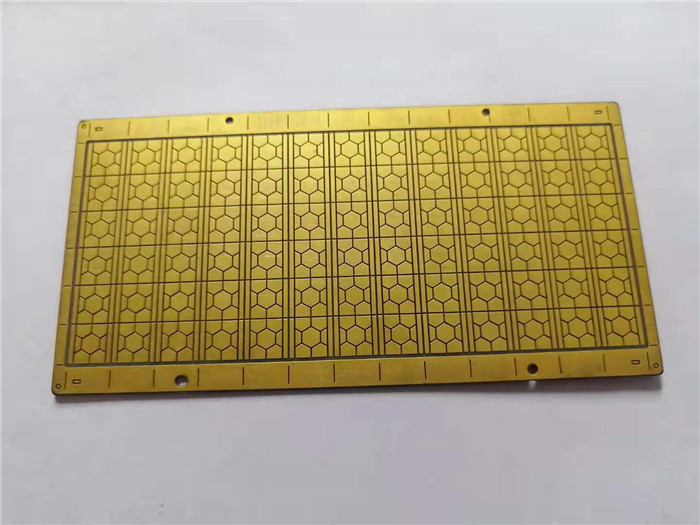

Beryllium Oxide(BeO) Products:

Why Use Beryllium Oxide (BeO) Ceramics?

Beryllium oxide (BeO) ceramics have the characteristics of high thermal conductivity, high melting point, high strength, high insulation, high chemical and thermal stability, low dielectric constant, low dielectric loss and good process adaptability. It is used in special metallurgy, Vacuum electronics technology, nuclear technology, microelectronics and optoelectronics technology are widely used.

Mechanical Properties

| Properties | Unit | 97%BeO | 99%BeO | 99%Al2O3 |

| Colour | —— | White | White | Yellow |

| Density | g/cm³ | ≥2.85 | ≥2.85 | 3.85 |

| Flexural Strength | MPa | ≥170 | ≥190 | 310 |

| Air Tightness | Pa.m³/s | ≤10×10-11 | ≤10×10-11 | —— |

| Average Grain Size | um | 12~30 | 12~30 | —— |

Thermal Properties

| Properties | Unit | 97%BeO | 99%BeO | 99%Al2O3 |

| Maximum Use Temperature | ℃(No load) | 1600 | 1600 | 1650 |

| Thermal Conductivity @ 25°C | W/(m・K) | ≥200 | ≥240 | 29 |

| Thermal Conductivity @ 100°C | W/(m・K) | ≥160 | ≥190 | —— |

| Thermal Expansion a at 25–500°C | 1 x 10-6/°C | 7~8.5 | 7~8.5 | 7~8 |

| Thermal Shock Resistance | ℃(Put in water) | 800 | 800 | 200 |

Electrical Properties

| Properties | Unit | 97%BeO | 99%BeO | 99%Al2O3 |

| Dielectric Constant | 1MHz | 6.9±0.4 | 6.9±0.4 | 9.9 |

| Dielectric Strength | KV/mm | 50 | 50 | 15 |

| Dielectric Loss | 1MHz | 4 x 10-4 | 4 x 10-4 | 4 x 10-4 |

| Volume Resistivity @ 25°C | Ω・cm | >1014 | >1014 | >1014 |

| Volume Resistivity @ 300°C | Ω・cm | >1011 | >1011 | >108 |

*The values are typical material properties and may vary according to products configuration and manufacturing process. For more details, Please feel free to contact us.

What can BeO Ceramics Be Used For?

- High-end laser diodes for commercial systems;

- Industrial laser metal cutting and marking equipment;

- Long-distance fiber optic transmission;

- Semiconductor processing equipment;

- End effector and arm assembly;

- Wafer chuck;

- Crucible for high temperature melting.

- In-situ X-ray analysis for downhole drilling;

- Concentrated photovoltaic (CPV) system;

- Transmitter, receiver, modulator and switch;

- Power amplifiers and drivers;

- Microwave and millimeter wave communication modules;

- Wireless communication;

- Point-to-point and point-to-multipoint radio;

- Satellite communication module.

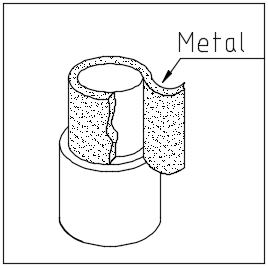

Toxicity Of Beryllium Oxide Ceramics

Although high-purity beryllium oxide ceramics are very safe, it cannot be ignored that beryllium oxide dust is toxic to the human body. This is like plastics that do not produce toxins when they are used, but the materials made of plastics are generally toxic for the same reason. Beryllium oxide ceramics processed into solid forms will not cause special harm to human health.

Beryllium Oxide Ceramics Custom Processing

Great Ceramic is your Beryllium Oxide machining specialist for your precision ceramic prototyping & manufacturing needs; we are always happy to use our many years of advanced ceramics experience to provide advice on materials, design, and application. If you would like to buy Beryllium Oxide plates, rods, tubes or custom machined components, please contact us and one of our experts will be happy to assist you.