Ceramic Pump

Ceramic filling pumps are a type of positive displacement pump that uses ceramic components to transport liquids. Ceramic is a material that is highly resistant to wear and corrosion, making it ideal for use in demanding applications. Customized ceramic filling pumps can be designed to meet the specific needs of a wide range of industries, including pharmaceutical, food and beverage, and chemical.

Custom Machined Ceramic Pumps

Our company specializes in designing and manufacturing high-quality customized ceramic filling pumps for precise fluid transfer in demanding industries.

Benefits of Ceramic Filling Pumps

- High precision: Ceramic filling pumps can deliver liquids with a high degree of precision, making them ideal for applications where accuracy is critical.

- Long service life: Ceramic is a highly durable material, so ceramic filling pumps have a long service life, even in demanding applications.

- Low maintenance: Ceramic filling pumps require very little maintenance, which can save businesses time and money.

- Chemical resistance: Ceramic is highly resistant to a wide range of chemicals, making it ideal for use in applications where corrosive liquids are being handled.

- Hygienic design: Ceramic filling pumps can be designed to meet the highest hygienic standards, making them ideal for use in the food and beverage and pharmaceutical industries.

- Customized Design: A customized ceramic filling pump can be designed to fit your specific application, taking into account factors such as space constraints, temperature, and pressure. This ensures that the pump is optimized for your needs, resulting in improved performance and efficiency.

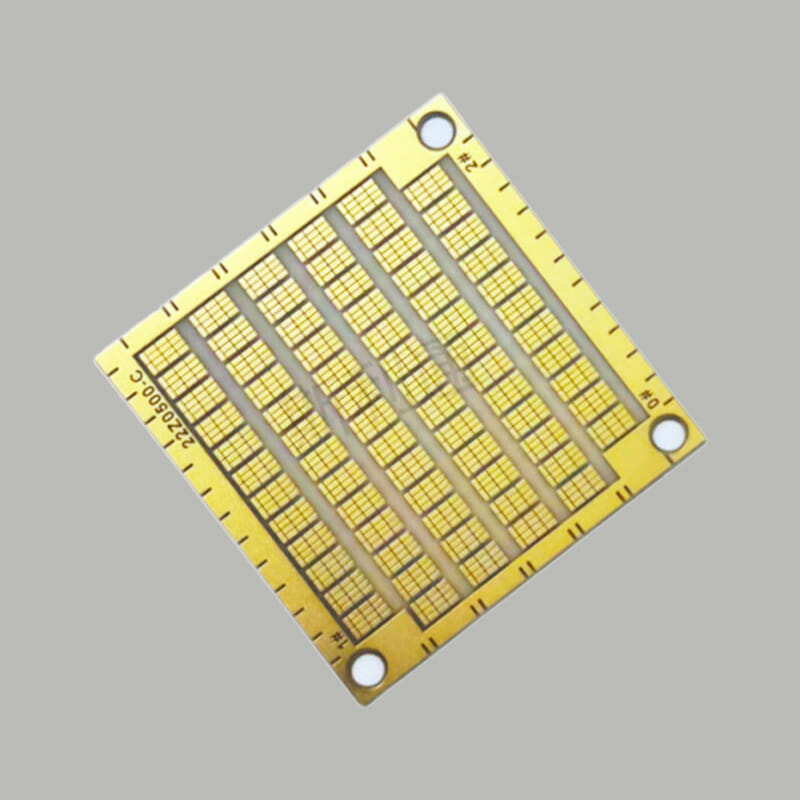

Ceramic Pump Materials

We utilize high purity ceramic materials tailored for each pump:

- Alumina for wear resistance

- Zirconia for strength and chemical resistance

- Silicon nitride provides thermal shock resistance and strength

- Silicon carbide for hardness and low friction

- Other ceramics

Our in-house machine shop provides precision ceramic machining to enable innovative pump designs.

Applications of Customized Ceramic Filling Pumps

- Pharmaceutical: Ceramic filling pumps are used to fill vials, ampoules, and syringes with a variety of pharmaceutical products.

- Food and beverage: Ceramic filling pumps are used to fill bottles and cartons with a variety of food and beverage products, such as beer, wine, juice, and milk.

- Chemical: Ceramic filling pumps are used to fill drums and containers with a variety of chemical products, such as acids, bases, and solvents.

- Other applications: Ceramic filling pumps are also used in a variety of other applications, such as ink filling, paint filling, and adhesive filling.

Ceramic filling pumps are versatile and reliable solutions for a variety of applications. If you are looking for a pump with high accuracy, long life and low maintenance, please contact our engineering team to discuss your custom ceramic filling pump solution needs!

Additional Information

Ceramic filling pumps are typically more expensive than other types of pumps, such as metal or plastic pumps. However, the higher initial cost is often offset by the longer service life and lower maintenance requirements of ceramic pumps.

Ceramic filling pumps can be customized to meet the specific needs of any application. This includes factors such as flow rate, pressure, viscosity, materials of construction, and hygienic requirements.

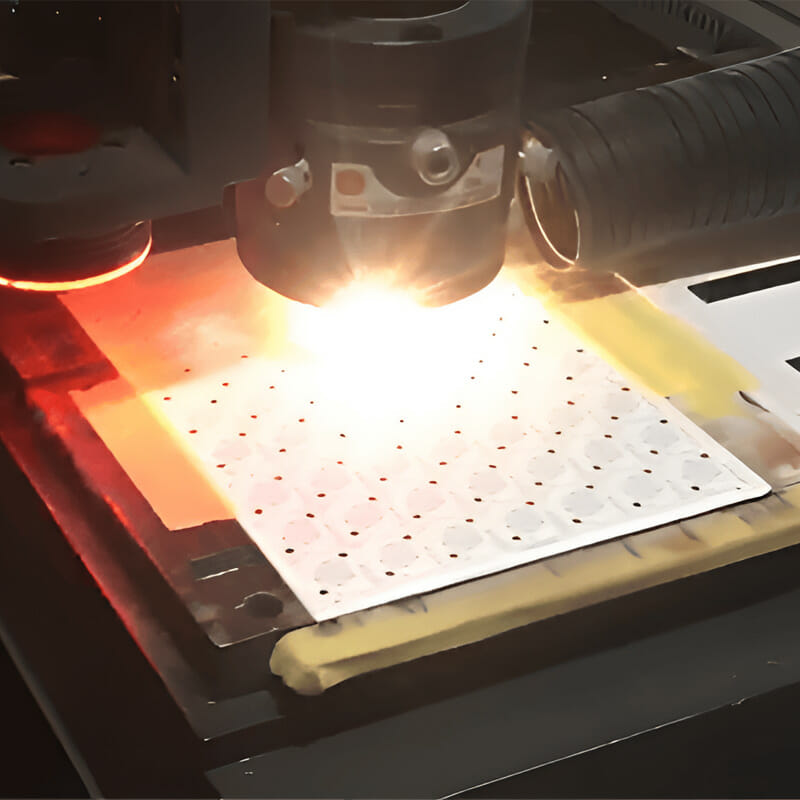

Learn about laser processing of ceramic substrates

Learn about ceramic substrate metallization