Alumina Ceramic(Al2O3)

Alumina ceramics(Al2O3) is the most common technical ceramics material, with very high hardness. The material has excellent properties in terms of electrical insulation, high thermal conductivity, high chemical resistance, good wear resistance and low thermal expansion.

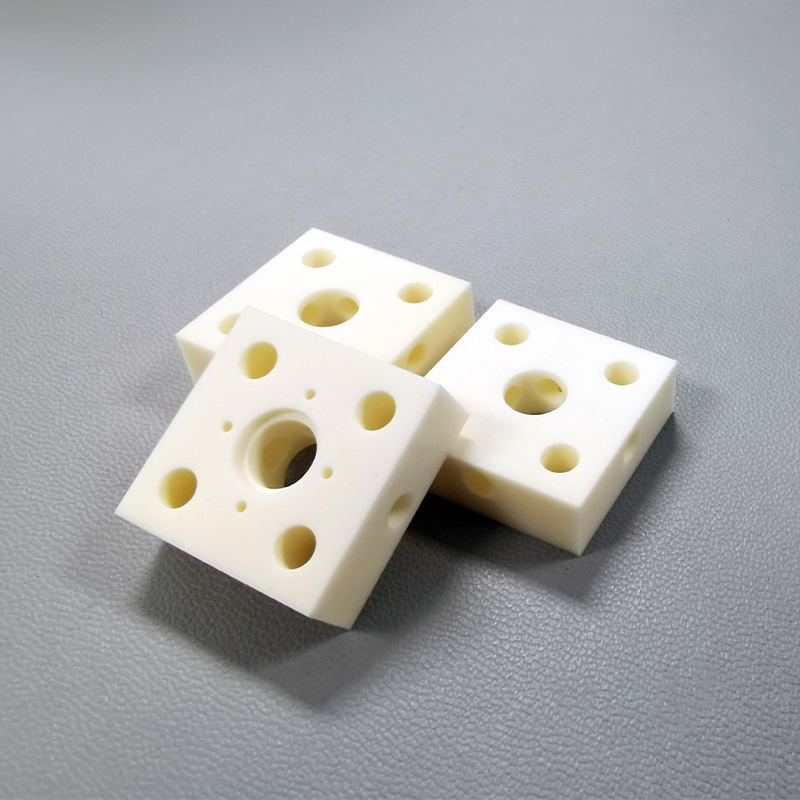

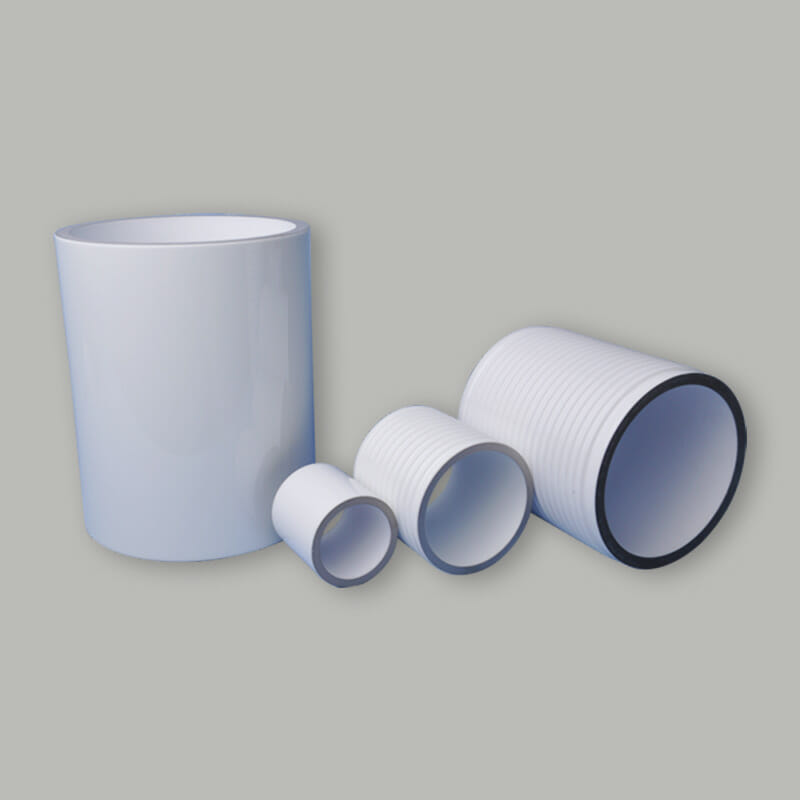

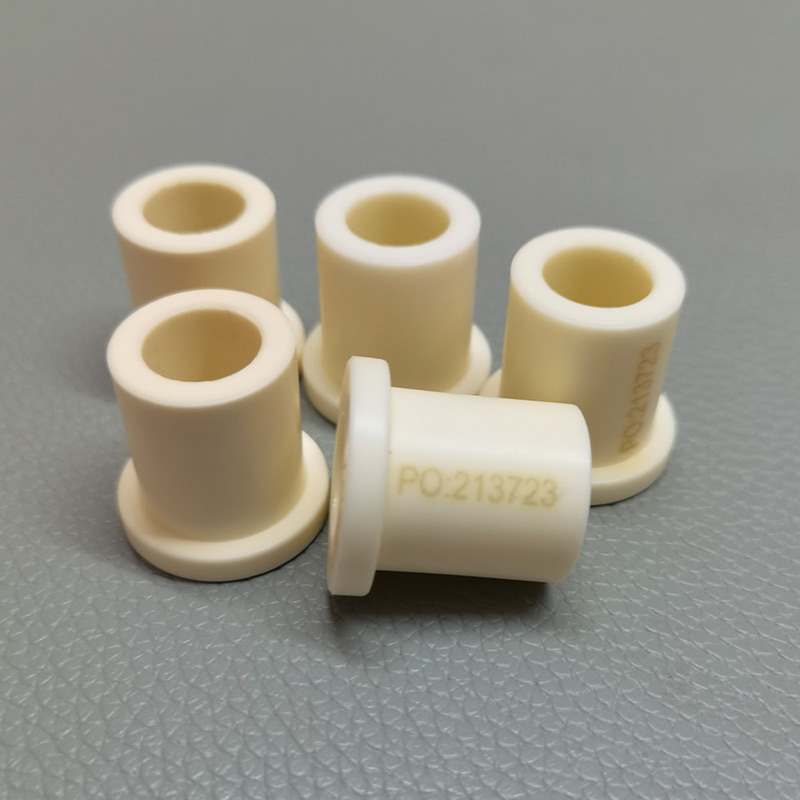

Alumina ceramics can be divided into multiple application grades according to their alumina content. Among them, 99% alumina ceramic materials are used to make high-temperature crucibles, refractory furnace tubes and special wear-resistant materials(such as ceramic bearings, ceramic seals, and water valve discs.); 95%-96% alumina porcelain is mainly used for corrosion-resistant, wear-resistant parts and circuit substrates.

Features of alumina ceramic

- Relatively low density;

- Extremely high operating temperature;

- Very high hardness and compressive strength;

- Excellent electrical insulation properties;

- Corrosion and wear resistance;

- Biologically inert, food compatibility。

Alumina Ceramic Properties

The following only lists the performance parameters of the three most common aluminum oxide ceramics. Normally, alumina ceramics are composed of these types.

Mechanical Properties

| Properties | Unit | 95%Al2O3 | 99%Al2O3 | 99.5%Al2O3 |

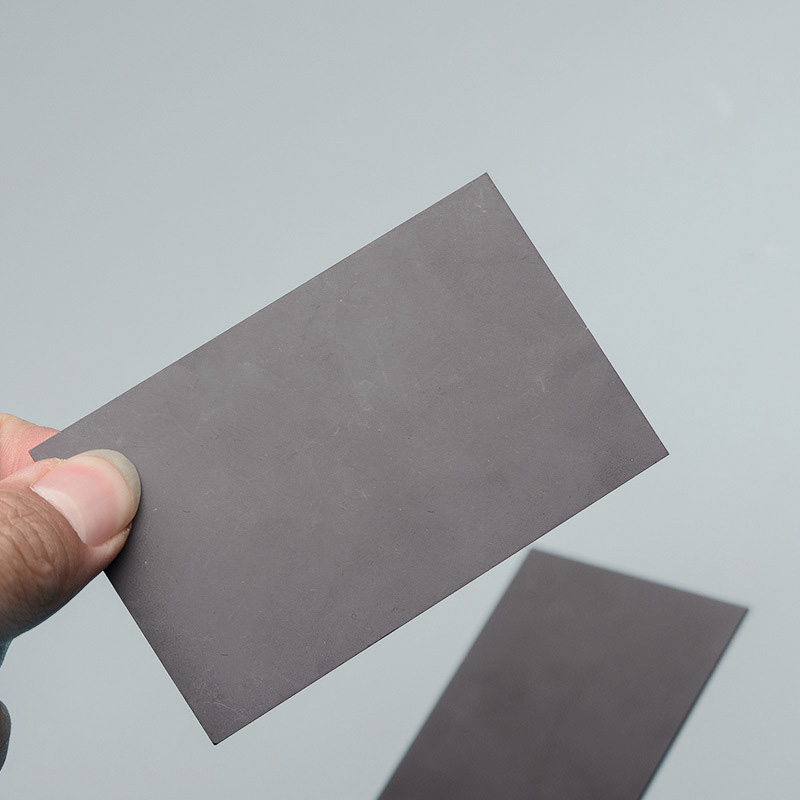

| Colour | —— | White | Yellow | Yellow |

| Density | g/cm³ | 3.7 | 3.85 | 3.9 |

| Hardness | GPa | 13.7 | 15.2 | 15.7 |

| Compressive Strength | MPa | 2000 | 2160 | 2350 |

| Flexural Strength | MPa | 280 | 310 | 350 |

| Fracture Toughness | MPa・m1/2 | 3~4 | 3~4 | 4.5 |

| Modulus of Elasticity | GPa | 320 | 360 | 370 |

| Poissons Ratio | —— | 0.23 | 0.23 | 0.23 |

Thermal Properties

| Properties | Unit | 95%Al2O3 | 99%Al2O3 | 99.5%Al2O3 |

| Maximum Use Temperature | ℃(No load) | 1650 | 1650 | 1650 |

| Thermal Conductivity @ 20°C | W/(m・K) | 24 | 29 | 32 |

| Thermal Expansion a at 20–400°C | 1 x 10-6/°C | 7~8 | 7~8 | 7~8 |

| Specific Heat | J/(kg・K) | 780 | 790 | 780 |

| Thermal Shock Resistance | ℃(Put in water) | 200 | 200 | 200 |

Electrical Properties

| Properties | Unit | 95%Al2O3 | 99%Al2O3 | 99.5%Al2O3 |

| Dielectric Constant | 1MHz | 9.4 | 9.9 | 9.9 |

| Dielectric Strength | V/m | 15 x 106 | 15 x 106 | 15 x 106 |

| Dielectric Loss | 1MHz | 4 x 10-4 | 4 x 10-4 | 4 x 10-4 |

| Volume Resistivity @ 25°C | Ω・cm | >1014 | >1014 | >1014 |

| Volume Resistivity @ 500°C | Ω・cm | >108 | >108 | >1010 |

*The values are typical material properties and may vary according to products configuration and manufacturing process. For more details, Please feel free to contact us.

What can alumina ceramics be used for?

- Wire and wire guide;

- Mechanical seal components:

- Machine parts;

- Electronic parts and substrates;

- Ballistic armor;

- Roller and ball bearings;

- Wear-resistant lining;

- Semiconductor parts;

- Precision shafts and sleeves in high-wear environments;

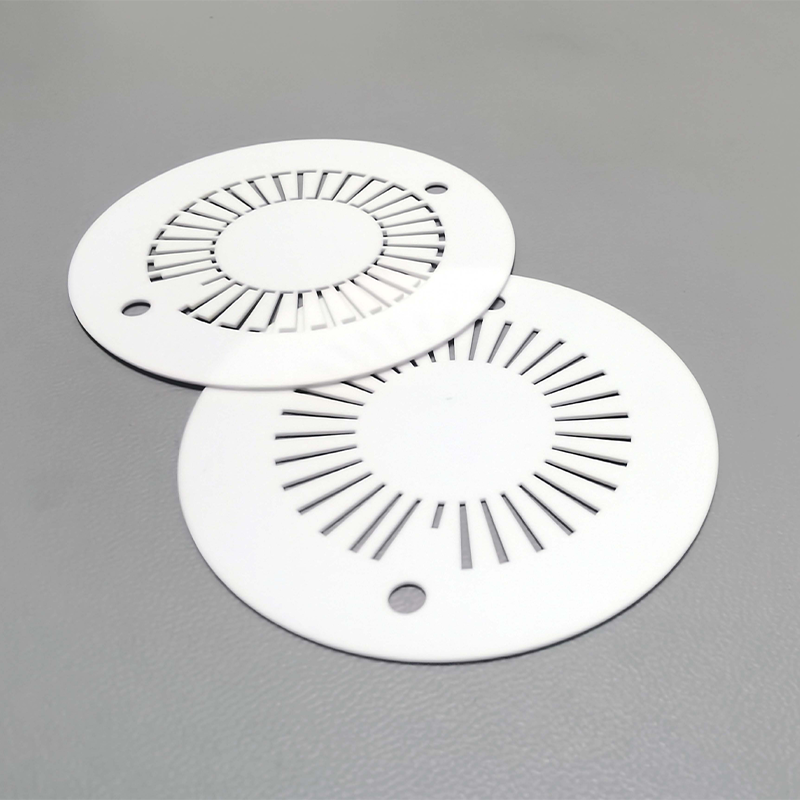

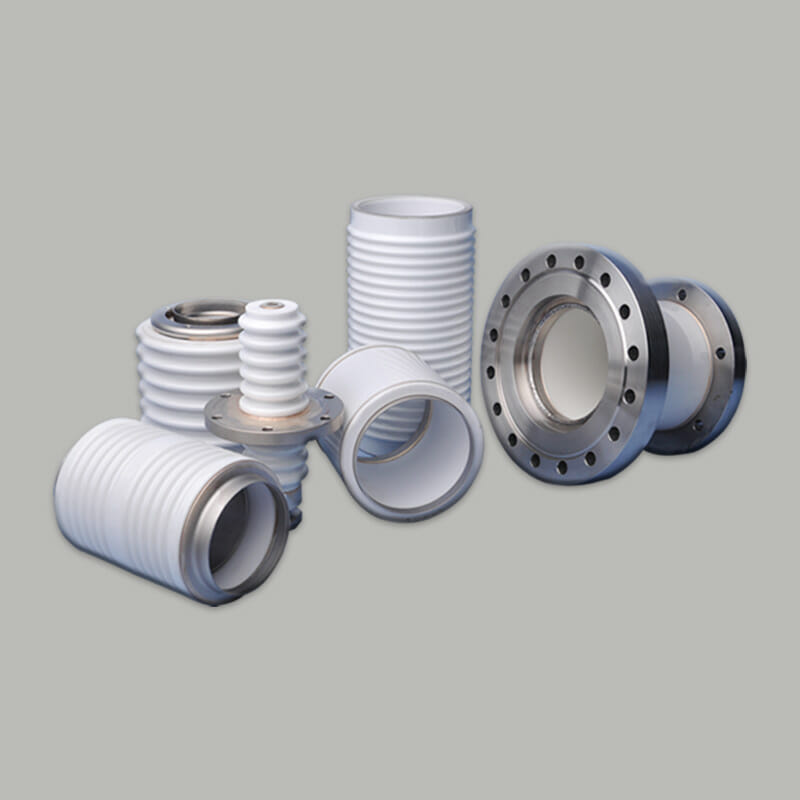

Alumina Ceramic Components

Alumina Ceramic Machining & Casting

Great Ceramic is an expert in the production of technical ceramics. Since 2013, we have participated in and provided more than 3,000 precision ceramic products to hundreds of companies.

We can provide you with ceramic machining, ceramic materials, ceramic casting, ceramic metal packaging and surface metallization services. We are committed to providing products and services that meet or exceed customer quality requirements.

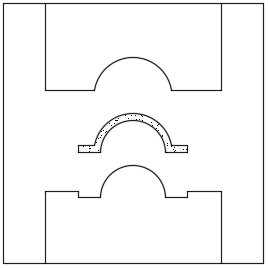

Ceramic Machining

Ceramic Materials

Ceramic Casting

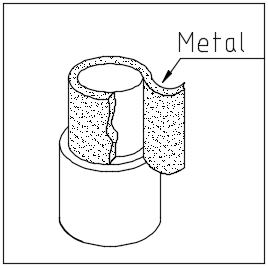

Ceramics & Metals

Alumina Oxide Ceramic Component Machining

Great Ceramic is your alumina ceramic machining expert and can meet your technical ceramic prototyping needs. We are always happy to use our years of advanced ceramic experience to provide advice on materials, designs and applications. If you want to buy alumina plates, rods, tubes or custom machined parts, please contact us and each of our experts will be happy to help you.