Aluminum Nitride Ceramic Disc

Aluminum nitride ceramic discs have high thermal conductivity, low dielectric coefficient and dielectric loss, and excellent mechanical properties. They are widely used in semiconductor equipment, electric vehicles, charging piles, IGBT modules, energy storage batteries, LED and laser equipment, Radiators, high-power devices and other fields.

ALN Disc Manufacturing Company

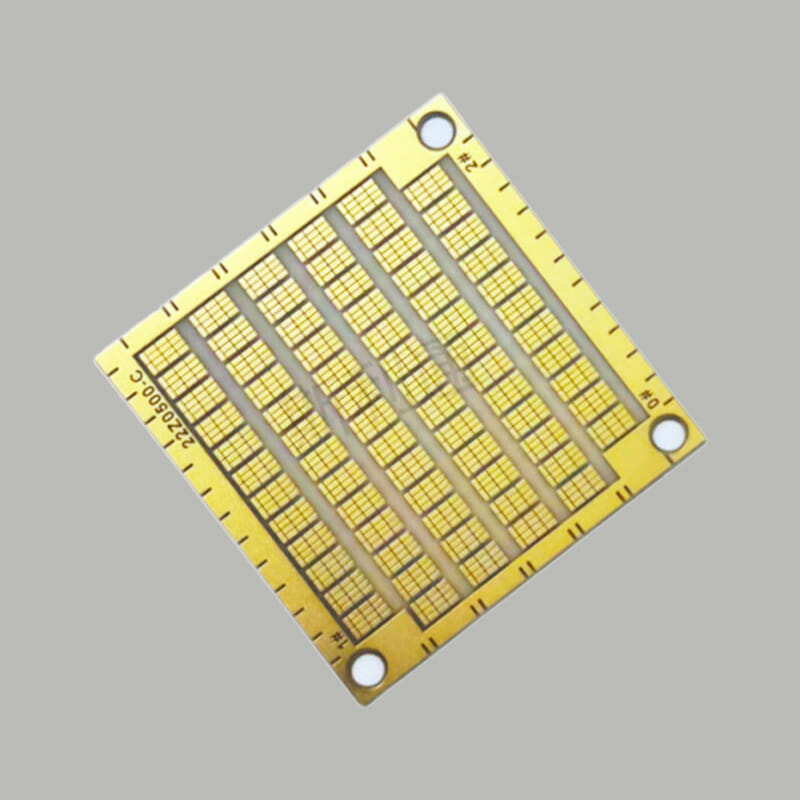

Great Ceramic offers aluminum nitride (ALN) ceramic discs that are die cast (or isostatically pressed) in a mold. It has good electrical insulation properties, can withstand large instantaneous current shocks, has high mechanical strength, is non-toxic and harmless, etc. The size of the disc can be customized according to customer needs, with a maximum diameter of 450 mm and a maximum thickness of 20 mm.

Properties of AlN Ceramic Disc

Basic properties of ceramic disc

| Items | Unit | AlN Disc |

| Color | – | Gray/Beige |

| Volume density | g/cm³ | 3.25 |

| Surface roughness | um(Ra) | <0.8 |

| Camber | length ‰ | ≤2.5 |

Mechanical properties of disc

| Items | Unit | AlN Disc |

| Bending Strength | MPa | ≥350 |

| Fracture Toughness | MPa·m1/2 | 3.0 |

| Vickers Hardness | GPa | 11 |

Thermal properties of the disc

| Items | Unit | AlN Disc |

| Thermal conductivity | W/m·k(25℃) | ≥170 |

| Thermal expansion coefficient | ×10-6/k (20℃~800℃) | 4~6 |

| Thermal shock resistance | ≥10(800℃) | No cracks |

| Heat capacity | J/(kg·k) | 720 |

Electrical properties of the disc

| Items | Unit | AlN Disc |

| Volume resistance | Ω·cm(20℃) | 1.5×1013 |

| Dielectric constant | 1MHz | 10.6 |

| Dielectric loss | 1MHz | 4.6×10-4 |

| Dielectric strength | KV/mm | ≥20 |

Note: Each batch may be different, for reference only.

Note: Please view it on your computer.

Advantages Of Aluminum Nitride Discs

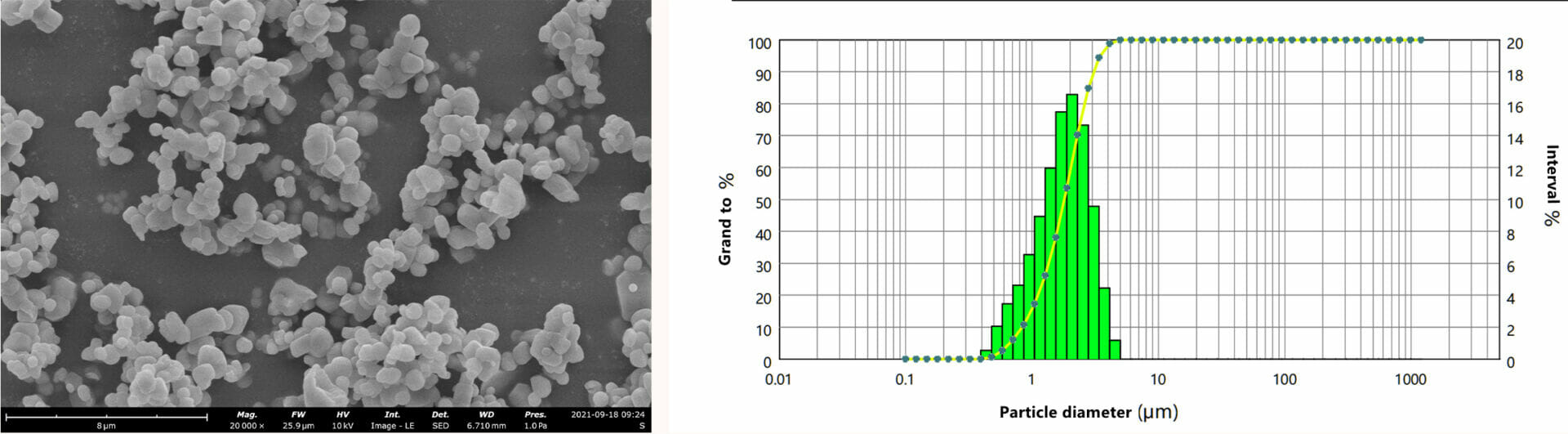

From the scanning electron microscope pictures, the grain size of the aluminum nitride disk is uniform, and there is no obvious phenomenon of larger grains. It can achieve uniform heat distribution without causing temperature differences.

Dimensions Of Ceramic Disc

Great Ceramic offers aluminum nitride (AlN) ceramic discs in a variety of standardized sizes to meet customer needs. In addition, we also provide customers with disc customization services, and the size can be customized according to customer needs.

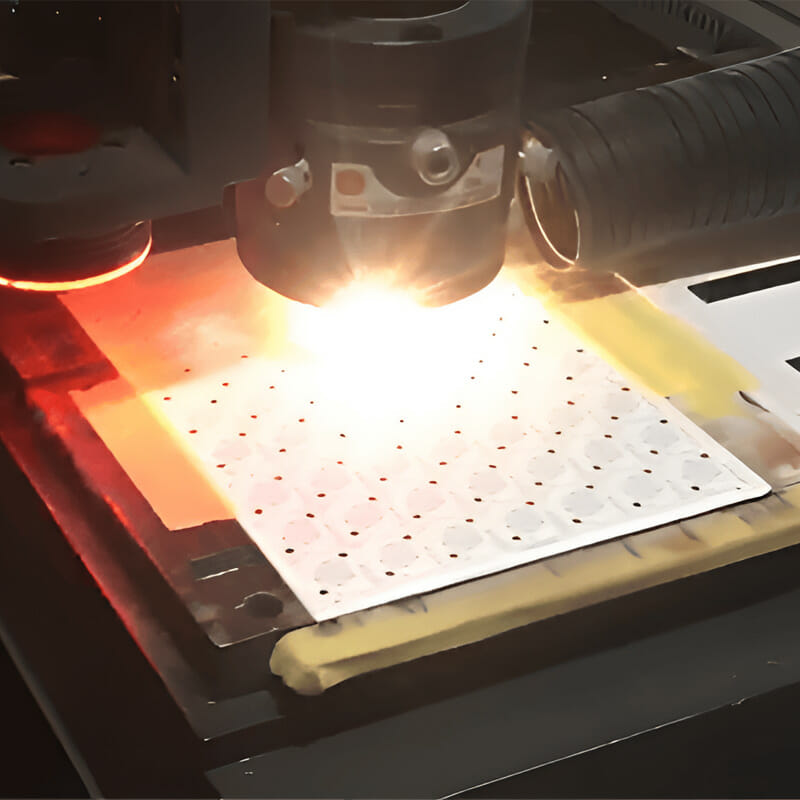

Learn about laser processing of ceramic substrates

Learn about ceramic substrate metallization