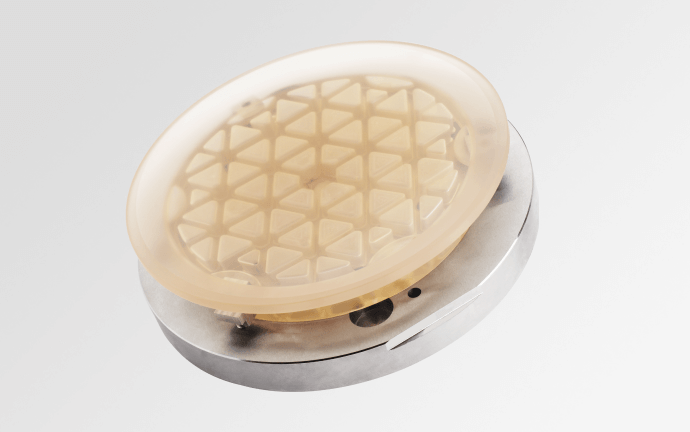

Precision Ceramic CNC Machining

Innovative materials and technologies continue to revolutionize the manufacturing landscape, with advanced ceramic CNC milling emerging as a game-changing solution for high-precision, complex component production. Great Ceramic Company pioneers this cutting-edge technology, offering a unique blend of technical ceramics’ exceptional properties and the precision and control of computer numerical control (CNC) machining.

Advantages of CNC machining

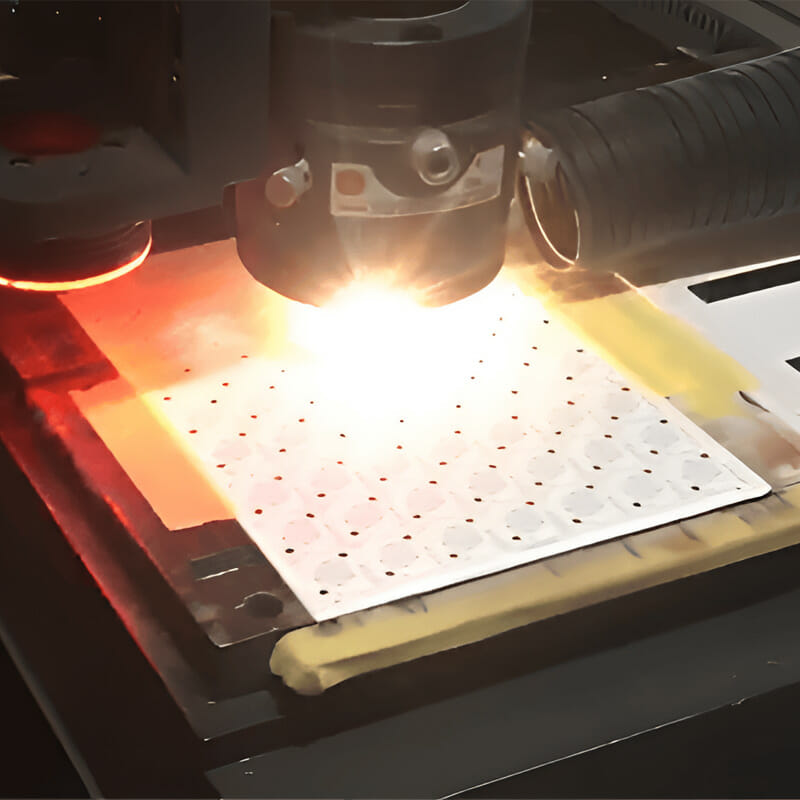

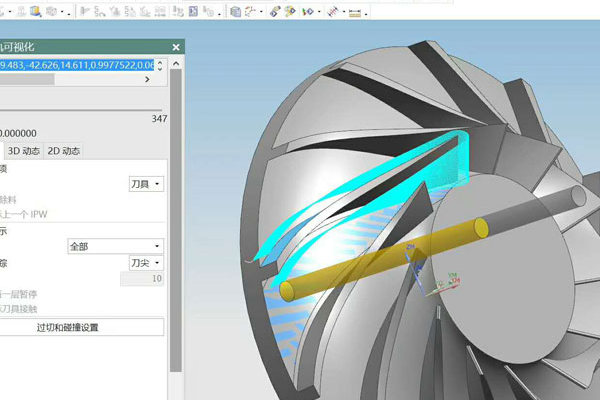

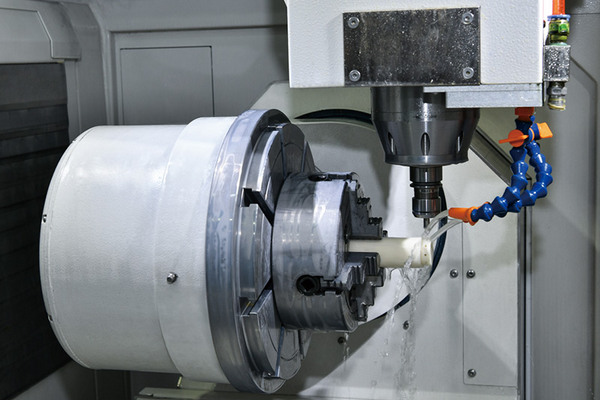

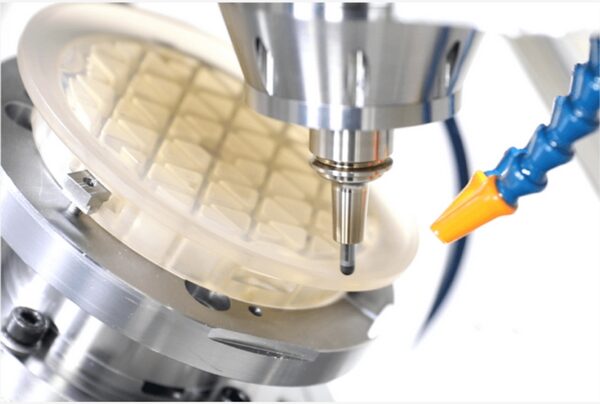

Advanced ceramic CNC milling harnesses the power of a computer-controlled milling machine equipped with specialized diamond cutting tools. The CNC program meticulously guides the tool’s movement, removing material from the ceramic workpiece to achieve the desired shape and features. This process enables:

Industry Applications:

The versatility of advanced ceramic CNC milling makes it a valuable tool across various sectors:

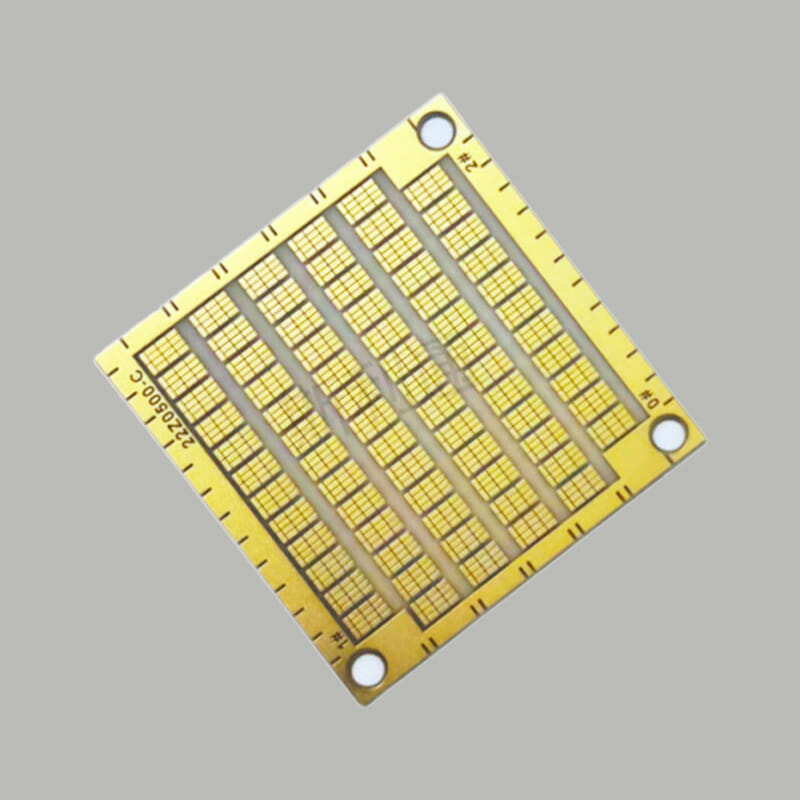

- Semiconductors: Fabricate heat sinks, substrates, and other components for high-performance electronics.

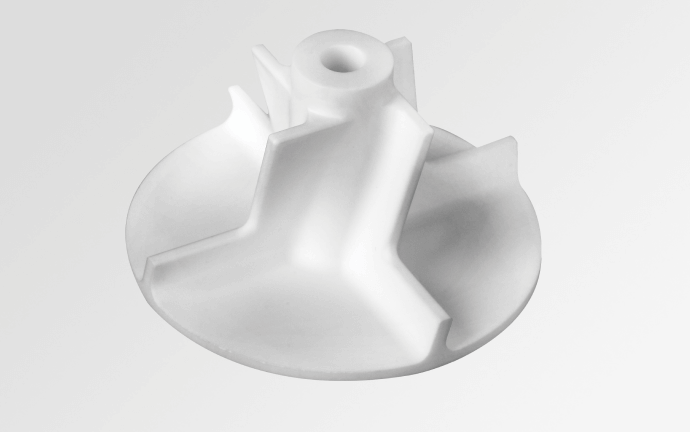

- Medical Devices: Create biocompatible implants, surgical tools, and other medical equipment.

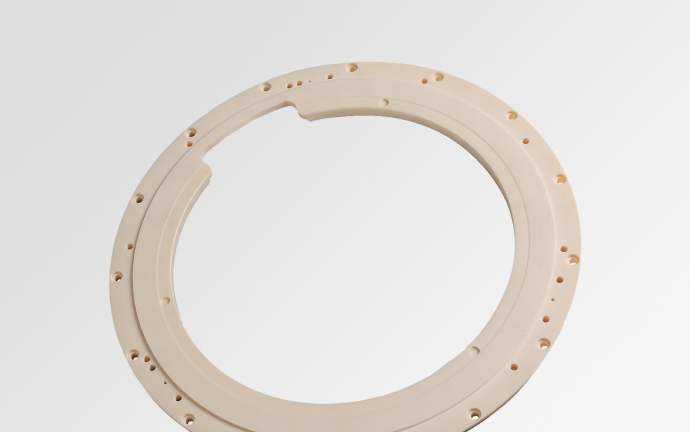

- Aerospace & Defense: Manufacture lightweight, high-strength parts for demanding aerospace applications.

- Energy & Power Generation: Produce components resistant to extreme temperatures and harsh environments.

- Automotive: Create wear-resistant components for engines, transmissions, and braking systems.

Great Ceramic’s Services:

We offer comprehensive ceramic CNC milling services to support your project from concept to completion:

- Design & Engineering Support: Our team collaborates with you to optimize your design for CNC milling and material selection.

- Prototyping & Production Runs: From rapid prototyping to high-volume production, we deliver exceptional results.

- Quality Control & Inspection: We ensure parts meet your exact specifications through rigorous quality checks.

Our advantage:

Specialty

Ultra-precision

4-axis Machining

5-axis Machining

Benefits Beyond the Basics:

- Sustainability: Durable, long-lasting ceramic components can reduce waste and replacement needs, promoting environmental responsibility.

- Cost-Effectiveness: While upfront costs might be higher, superior performance and extended lifespan of ceramic components can lead to long-term cost savings.

At Great Ceramic, we possess the expertise and technology to transform your ceramic design into a reality. Contact us today to discuss your specific requirements and discover how ceramic CNC milling can elevate your next project.

Contact US

Learn about ceramic substrate metallization