Aluminum Nitride(ALN)

Aluminum nitride(AlN) has high thermal conductivity and electrical insulation, and can be used in various electrical equipment. In addition, the thermal expansion coefficient and electrical insulation properties of aluminum nitride ceramics are very close to those of silicon wafers, and they have high thermal conductivity. Therefore, substrates made of aluminum nitride are widely used in the electronics industry.

AlN Density

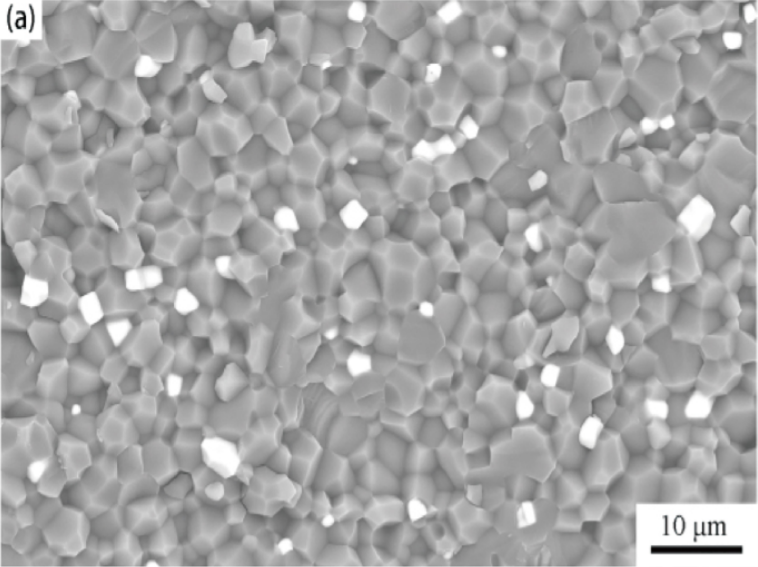

AlN is a covalent bond compound, atomic crystal, diamond-like nitride, hexagonal system, wurtzite crystal structure, non-toxic, white or grey white,The chemical composition is AI 65.81%, N 34.19%, theoretical density 3.26g/cm3.

Why Use Aluminum Nitride Ceramics?

- High thermal conductivity (>170W/m.K), close to BeO and SiC, more than 5 times that of Al2O3;

- The thermal expansion coefficient (4.5 *10-6℃) matches that of Si (3.5-4 *10-6℃) and GaAs (6 *10-6℃);

- Good electrical properties (dielectric constant, dielectric loss, bulk resistivity, dielectric strength);

- Good mechanical properties, higher bending strength than Al2O3 and BeO ceramics, sintering under normal pressure;

- Good light transmission characteristics;

- Non-toxic

Aluminum Nitride Properties

Mechanical Properties

| Properties | Unit | AN | IMAN | IMHTCAN |

|---|---|---|---|---|

| Colour | —— | Grey | Grey | Grey |

| Density | g/cm³ | 3.3 | 3.3 | 3.3 |

| Hardness | GPa | 11 | 11 | 11 |

| Compressive Strength | MPa | 2100 | 2100 | 2100 |

| Flexural Strength | MPa | 450 | 410 | 300 |

| Fracture Toughness | MPa・m1/2 | 3.5 | 2.6 | 2.4 |

| Modulus of Elasticity | GPa | 310 | 310 | 310 |

| Poissons Ratio | —— | 0.25 | 0.25 | 0.25 |

Thermal Properties

| Properties | Unit | AN | IMAN | IMHTCAN |

|---|---|---|---|---|

| Maximum Use Temperature | ℃(No load) | 1350 | 1350 | 1350 |

| Thermal Conductivity @ 25°C | W/(m・K) | >170 | >170 | >200 |

| Thermal Expansion at 40–400°C | 1 x 10-6/°C | 4.5 | 4.6 | 4.9 |

| Specific Heat | J/(kg・K) | 720 | 720 | 720 |

| Thermal Shock Resistance | ℃(Put in water) | 350 | 350 | 350 |

Electrical Properties

| Properties | Unit | AN | IMAN | IMHTCAN |

|---|---|---|---|---|

| Dielectric Constant | 1MHz | 8.8 | 8.5 | 8.5 |

| Dielectric Strength | ac-kV/mm | >15 | >15 | >15 |

| Volume Resistivity @ 25°C | Ω・cm | >1014 | >1014 | >1013 |

*The values are typical material properties and may vary according to products configuration and manufacturing process. For more details, Please feel free to contact us.

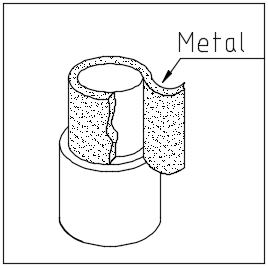

*Aluminum nitride is easy to be oxidized on the surface, which forms a layer of alumina.This helps to protect the material, but it affects the thermal conductivity (alumina is about 30 W/mK).In an oxidative atmosphere, this occurs at about 700℃.In an inert atmosphere, the layer protects AlN at temperatures as high as about 1350℃.When the temperature is higher than this, bulk oxidation occurs.

What Can AlN Ceramics Be Used For?

- Heat sinks & heat spreaders;

- Electrical insulators;

- Silicon wafer handling and processing;

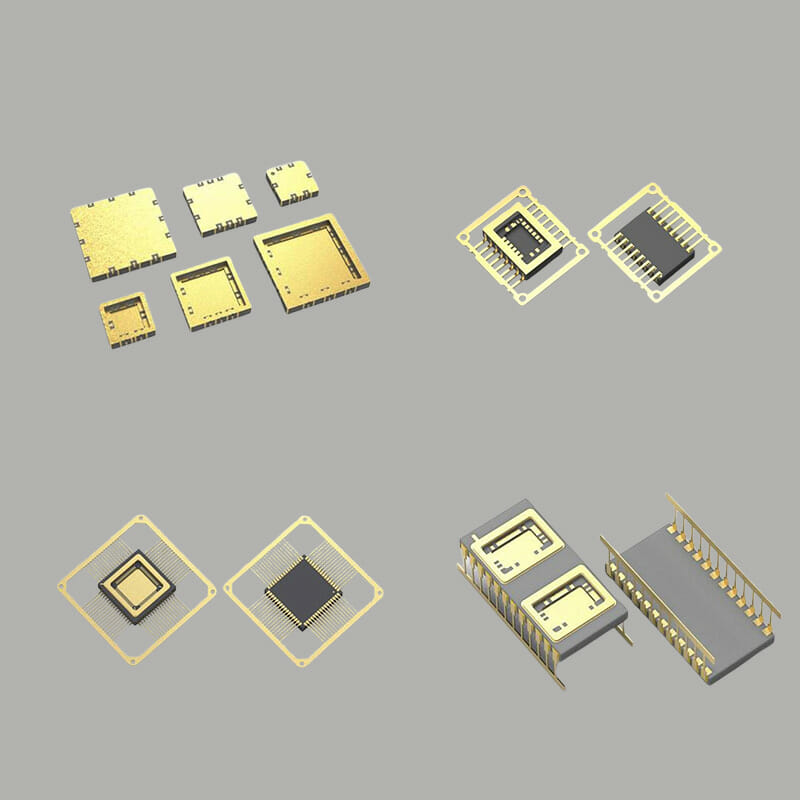

- Substrates & insulators for microelectronic devices;

- Substrates for electronic packages;

- Chip carriers for sensors and detectors;

- Laser heat management components;

- Molten metal fixtures;

- Packages for microwave devices;

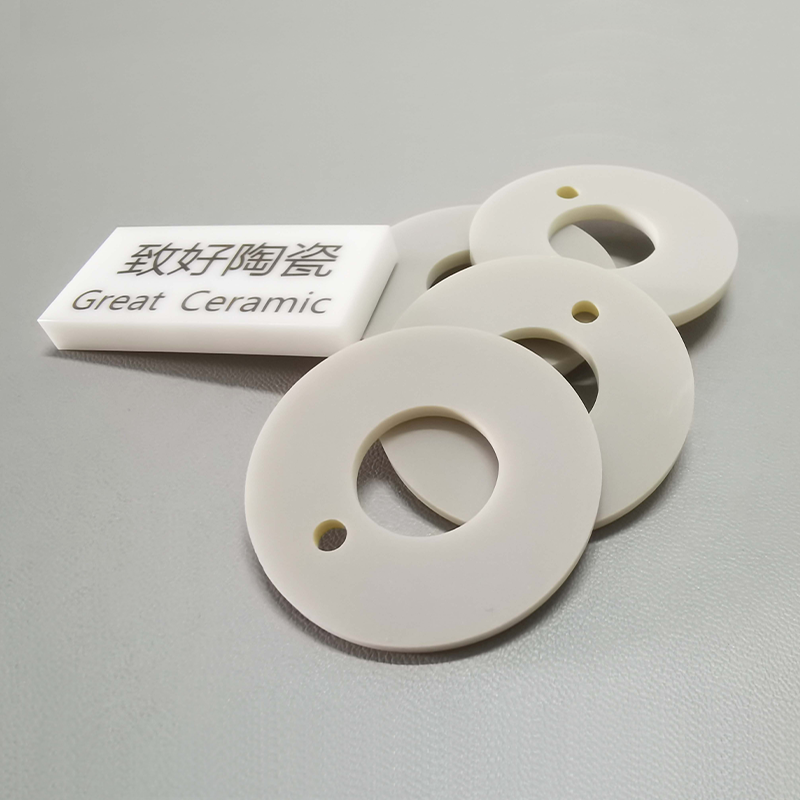

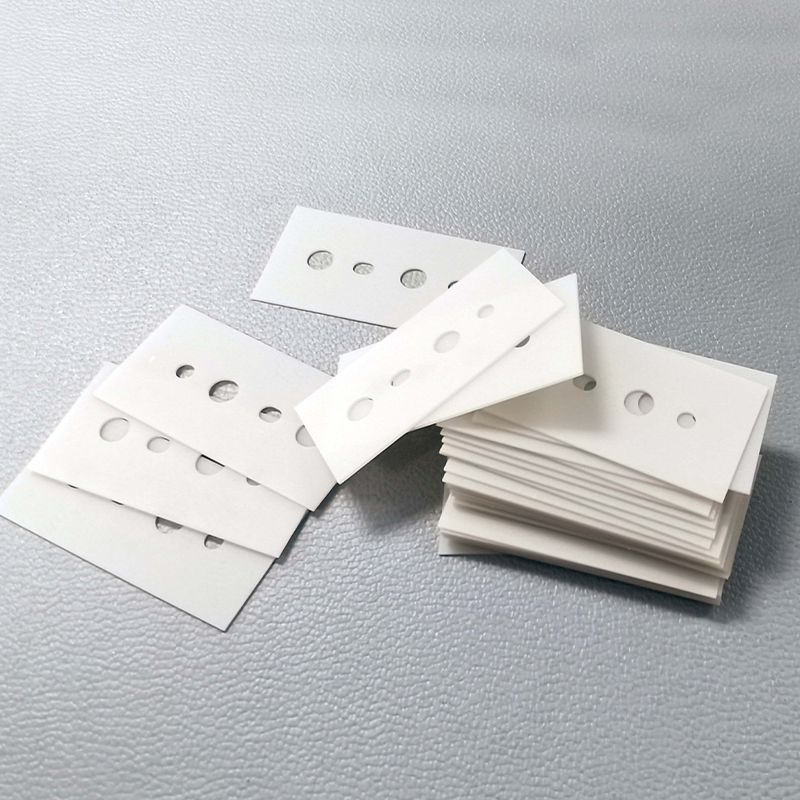

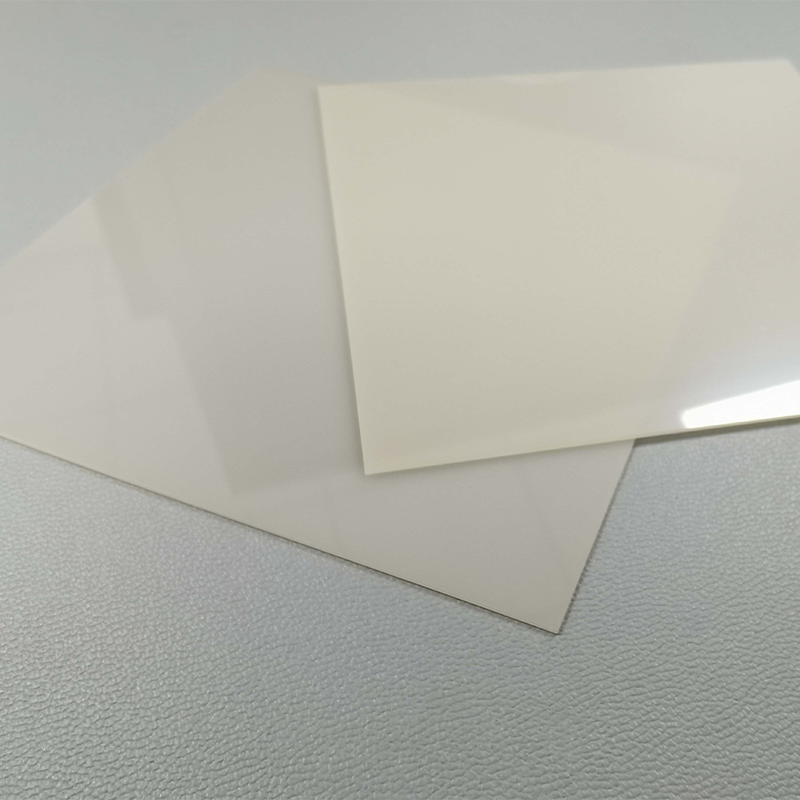

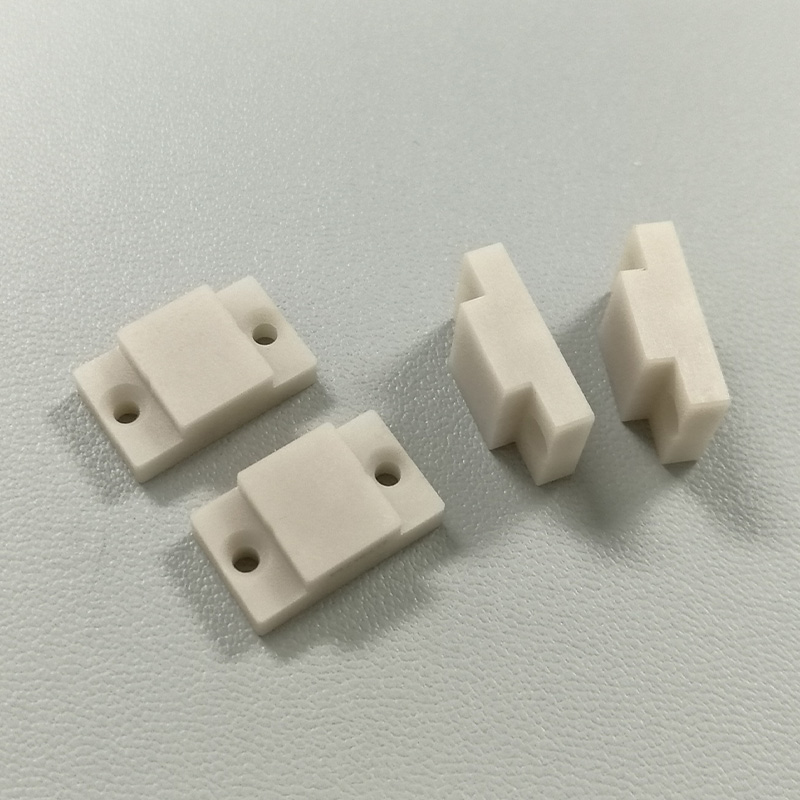

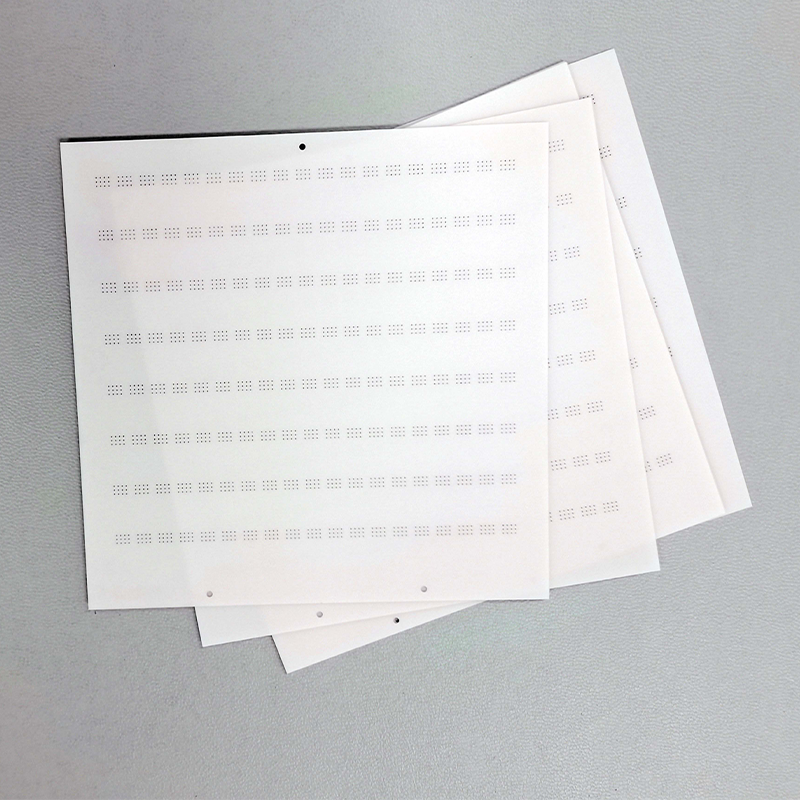

View Aluminum Nitride Substrates & Washer

The common structures of aln ceramic products include AlN substrates, AlN ceramic washers, sheets, etc.

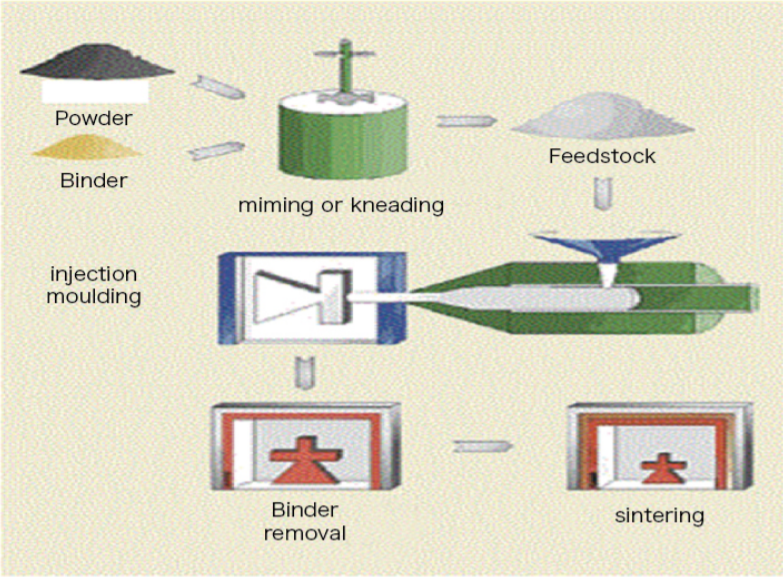

Machining Aluminum Nitride Ceramics

Great Ceramic is an expert in machining aluminum nitride ceramics. Since 2013, we have participated and provided more than 3000 kinds of precision ceramic products to hundreds of companies.

We can provide you with technical ceramic processing, ceramic materials, ceramic casting, ceramic metal encapsulation and surface metallization services. We are committed to providing products and services that meet or exceed our customers’ quality requirements.

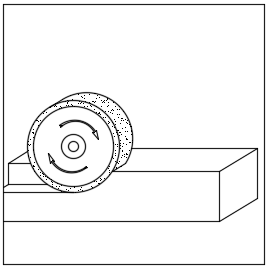

Machining

Materials

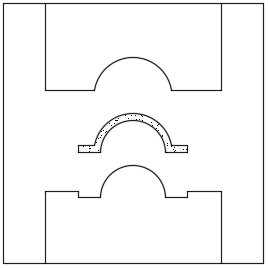

Mould

Metallization

Aluminum Nitride Ceramic Manufacturer

Great Ceramic is a professional AlN ceramic manufacturer that can meet your technical ceramic needs. We are always happy to use our many years of technical ceramics experience to advise on materials, designs and applications. If you would like to purchase AlN sheet, sheet, washer, bar or custom machined parts, please contact us and each of our experts will be happy to assist you.