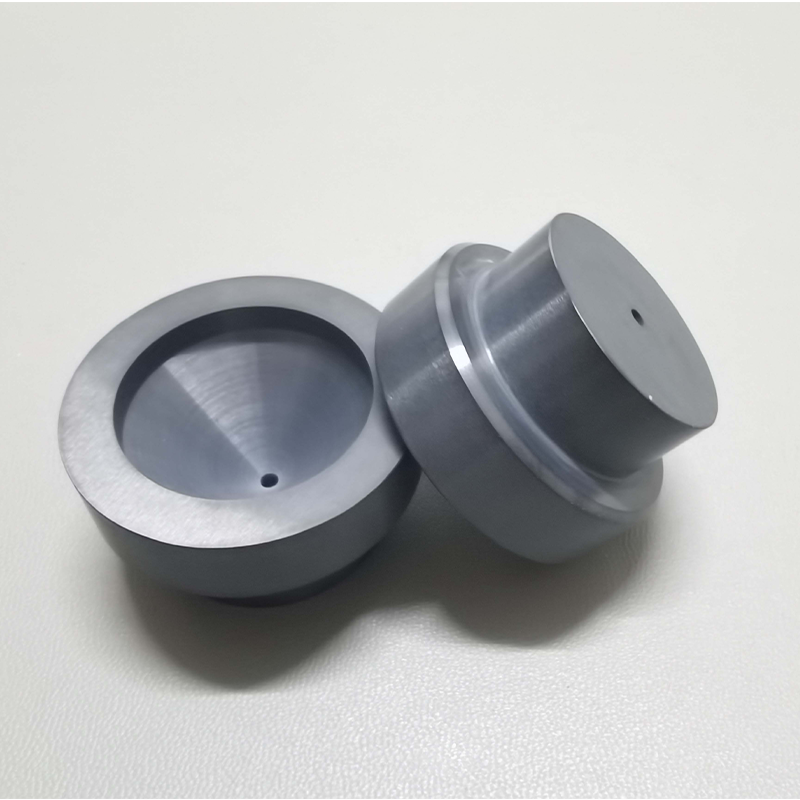

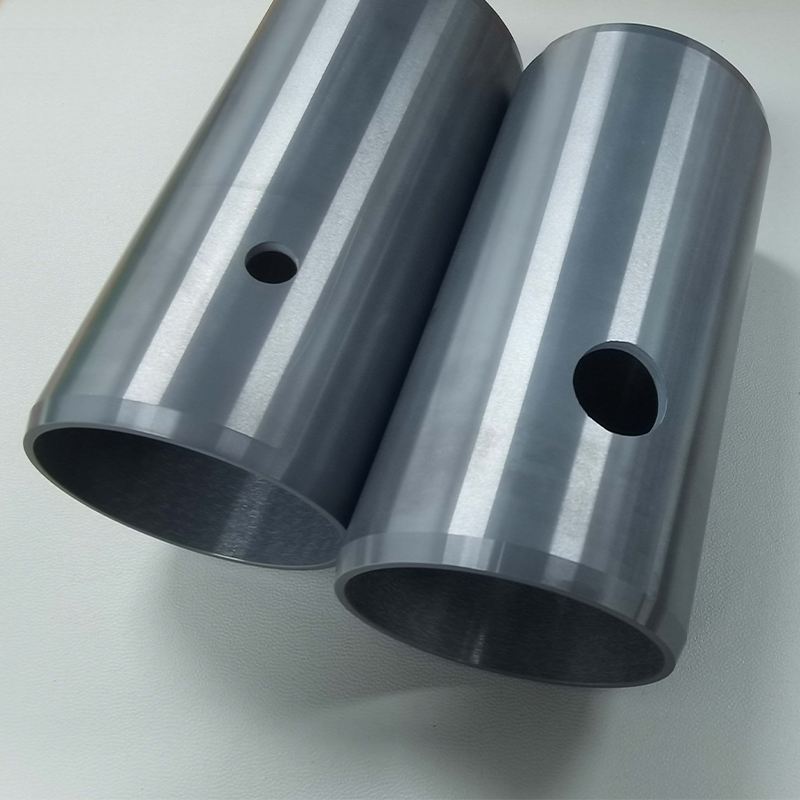

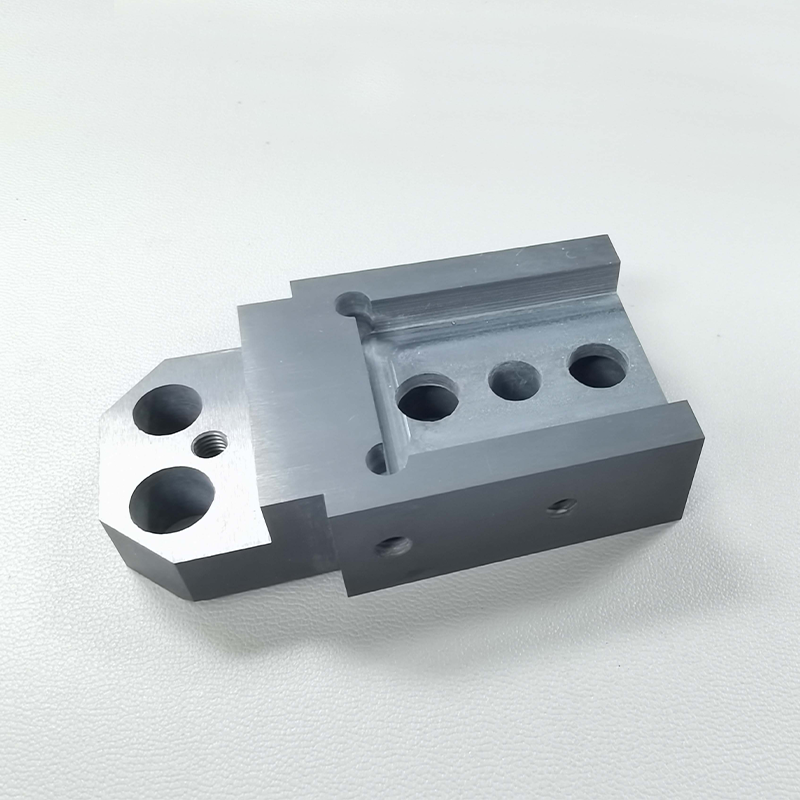

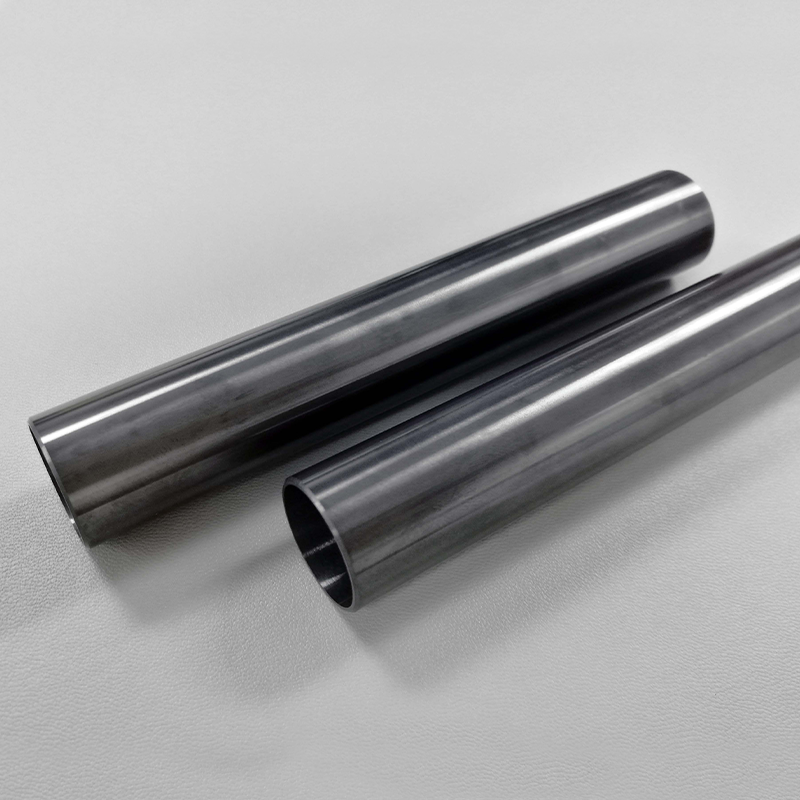

Silicon Nitride Ceramics(Si3N4)

Silicon nitride ceramics have the most versatile combination of mechanical, thermal and electrical properties and are a high-performance technical ceramic. It has a high temperature capability that exceeds most metals, and has excellent creep and oxidation resistance. In addition, its excellent thermal shock resistance and high abrasion resistance make it an excellent material capable of withstanding the harshest conditions in the most demanding industrial applications.

The Two Main Types Of Silicon Nitride Ceramics

Gas Pressure Sintered Silicon Nitride (GPSN)

This is the most popular method for producing high-strength and complex geometry silicon nitride components. The GPSN method uses a silicon nitride powder that has been mixed with sintering aids to promote liquid phase sintering (typically yttria, magnesium oxide, and/or alumina) as-well-as binders to improve the mechanical strength of green ceramic body. The powder is pressed into the desired form and green-machining can take place. The compacts are then placed into a furnace that has a pressurized nitrogen atmosphere to aid with densification and prevent the evaporation/decomposition of the silicon, nitrogen and additives.

Hot Pressed Silicon Nitride (HPSN)

HPSN is produced by uniaxially pressing silicon nitride powder (with sintering additives) while applying heat at the same time. A special type of press and die is required for this process. It produces a silicon nitride with excellent mechanical properties, however, only simple shapes can be produced. Because it is impossible to green-machine a component that is hot-pressed, diamond grinding is the only way to create complex geometries. Because of the high costs and difficulties associated with diamond grinding and hot-pressing, its use is typically limited to the production of simple components in small quantities.

Silicon Nitride Ceramics Properties

Features of Silicon Nitride Ceramics

- Very low density;

- Very high fracture toughness;

- Good bending strength;

- Excellent thermal shock resistance: high thermal stress parameters;

- Extremely high operating temperature.

Silicon Nitride Mechanical Properties

| Properties | Unit | GPSN | HPSN | HTCSNS |

|---|---|---|---|---|

| Colour | —— | Gray or black | Gray or black | Gray or black |

| Density | g/cm³ | 3.2 | 3.3 | 3.25 |

| Hardness | GPa | 15 | 16 | 15 |

| Compressive Strength | MPa | 2500 | 3000 | 2500 |

| Flexural Strength | MPa | 700 | 900 | 600~800 |

| Fracture Toughness | MPa・m1/2 | 5~7 | 6~8 | 6~7 |

| Modulus of Elasticity | GPa | 300 | 300 | 300~320 |

| Poissons Ratio | —— | 0.25 | 0.28 | 0.25 |

Silicon Nitride Thermal Properties

| Properties | Unit | GPSN | HPSN | HTCSNS |

|---|---|---|---|---|

| Maximum Use Temperature | ℃(No load) | 1100 | 1300 | 1100 |

| Thermal Conductivity @ 25°C | W/(m・K) | 15~20 | 20~25 | 80~100 |

| Thermal Expansion a at 40–400°C | 1 x 10-6/°C | 3 | 3.1 | 3 |

| Specific Heat | J/(kg・K) | 660 | 650 | 680 |

| Thermal Shock Resistance | ℃(Put in water) | 550 | 800 | —— |

Silicon Nitride Electrical Properties

| Properties | Unit | GPSN | HPSN | HTCSNS |

|---|---|---|---|---|

| Dielectric Constant | 1MHz | 6~8 | 8 | 7.8 |

| Dielectric Strength(6.35mm) | ac-kV/mm | 15 | 17 | —— |

| Volume Resistivity @ 25°C | Ω・cm | >1014 | >1014 | >1014 |

| Volume Resistivity @ 500°C | Ω・cm | >1010 | >1010 | >1010 |

*The values are typical material properties and may vary according to products configuration and manufacturing process. For more details, Please feel free to contact us.

*At not too high temperature, Si3N4 has high strength and impact resistance, but it will be damaged with the increase of use time above 1200℃, reducing its strength, and it is more prone to fatigue damage above 1450℃, so Si3N4 The operating temperature generally does not exceed 1300 ℃.

Silicon Nitride Ceramics Uses

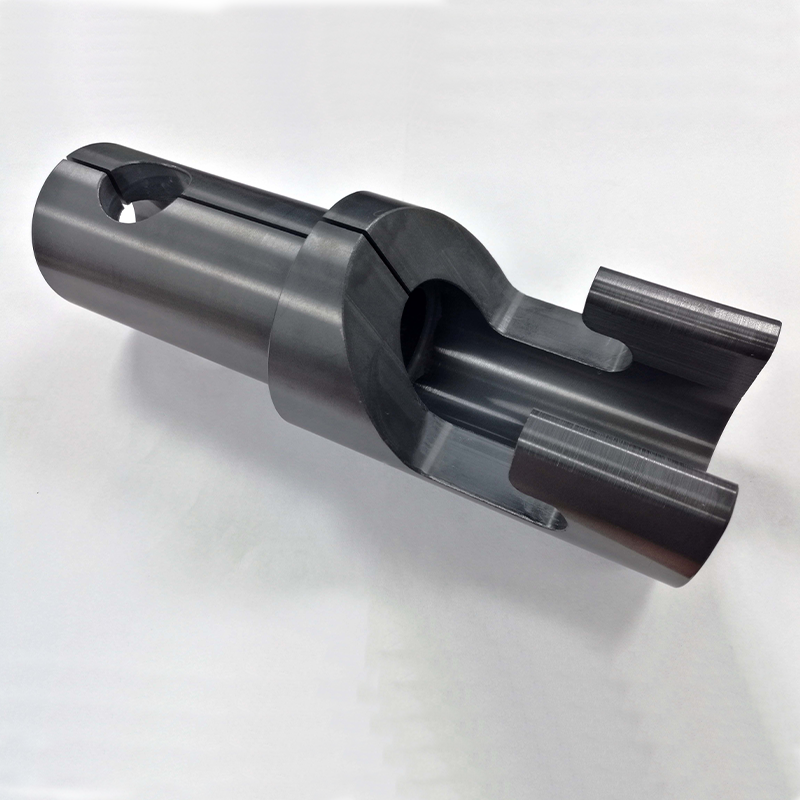

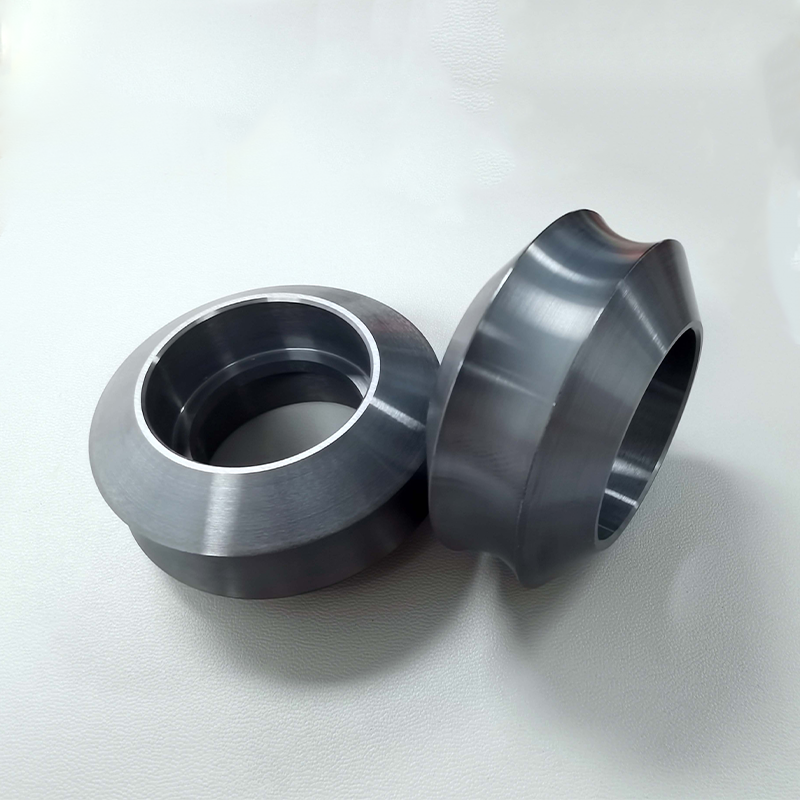

- Rotating ball & rollers bearings

- Cutting tools

- Engine components

- valves, rocker arm pads, seal faces

- Induction heating coil supports

- Turbine blades, vanes, buckets

- Welding & brazing jigs

- Heating Element components

- Crucibles

- Metal tube forming rolls and dies

- TIG / Plasma welding nozzles

- Weld positioners

- Precision shafts and axles in high wear environments

- Thermocouple sheaths & tubes

- Semiconductor Process Equipment

Silicon Nitride Ceramics Manufacturers

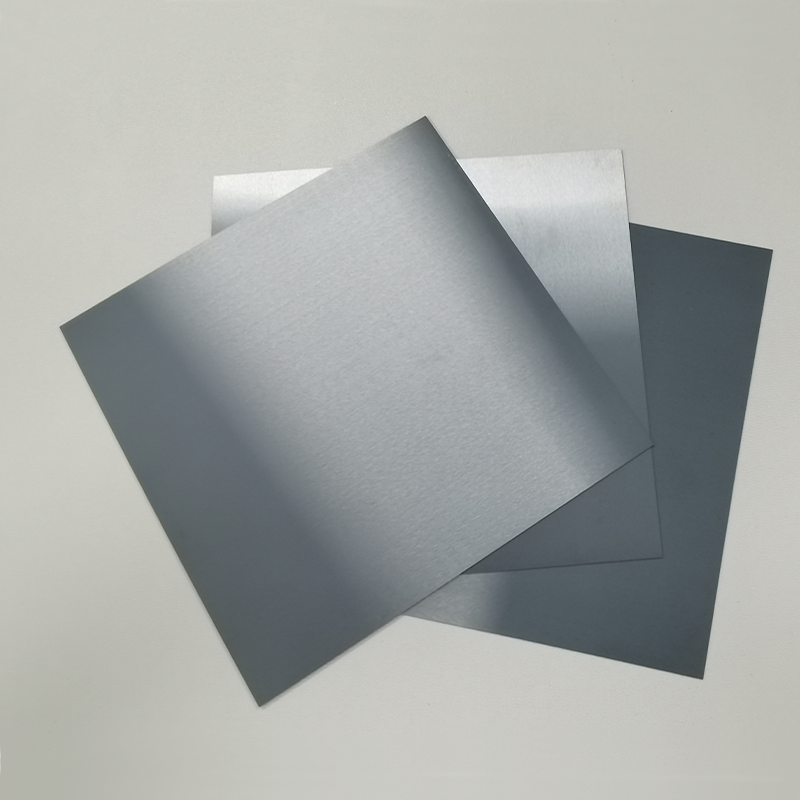

Great Ceramic is a professional manufacturer of silicon nitride ceramics. We are always happy to use our many years of experience in advanced ceramics to advise on materials, designs and applications. If you would like to purchase silicon nitride sheets, rods, tubes or custom machined parts, please contact us and each of our experts will be happy to assist you.