- Home

- Technical Ceramics Category And Application

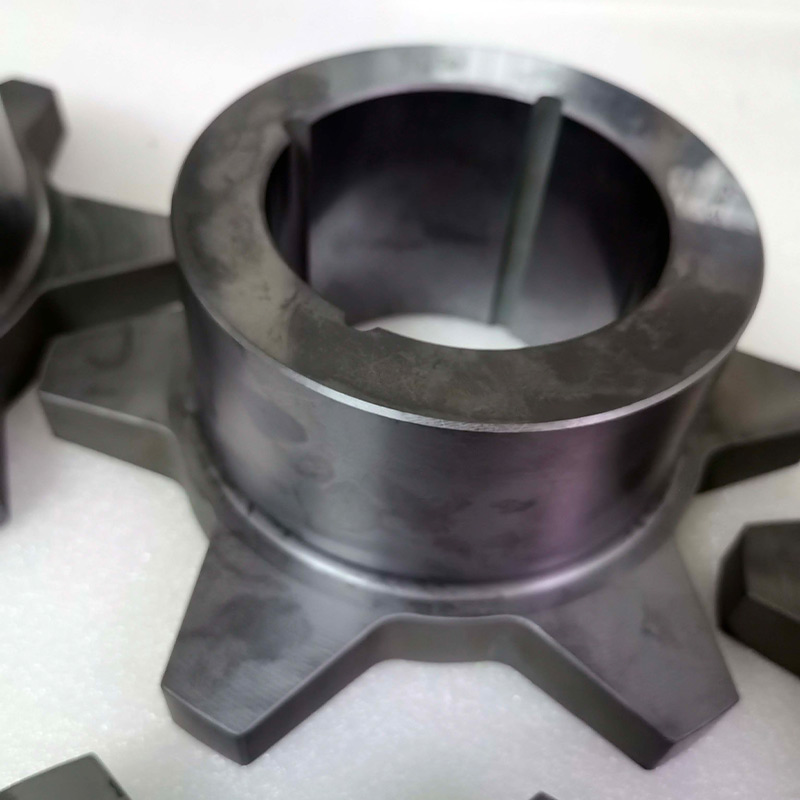

- Silicon Carbide Ceramic Impeller For Agitation

Silicon Carbide Ceramic Impeller For Agitation

- Can be customized according to requirements;

- Can make very complex structures;

- It can be used at 1400 ℃;

- High hardness, very wear-resistant;

- High corrosion resistance;

About Silicon Carbide Ceramic Impeller

The silicon carbide ceramic impeller is an industrial component used for stirring. Its main function is to generate strong eddy current and shear force through rotation, so that the mixture can be fully mixed and evenly distributed. It is usually used in the process of mixing solid particles and liquids, mixing gases and liquids, and mixing liquids and liquids.

The high hardness and wear resistance of the silicon carbide ceramic impeller enable it to withstand greater stirring force and friction force, and it is not easy to wear and cause a short life even if it is used for a long time. At the same time, its corrosion resistance is also very good, it can work in strong corrosive media such as acid and alkali, and its long-term service life is longer than other metal materials.

Advantages of SiC Ceramic Impeller

Silicon carbide ceramic impeller is a material widely used in industrial agitation, it has the following performance and advantages:

- Corrosion resistance: The silicon carbide ceramic impeller is a chemically inert material, which is not easily corroded by strong corrosive media such as acid and alkali, and has a longer long-term service life than other metal materials.

- Good wear resistance and hardness: the hardness of the silicon carbide ceramic impeller is as high as 2000HV, which is much harder than steel, so it can withstand high stirring force and friction force, and it is not easy to wear and cause the life to be too short.

- High temperature resistance: Silicon carbide ceramic impeller can work in high temperature environment, its heat resistance can reach above 1400℃, and it is not easy to deform, melt and other problems.

- Excellent mechanical strength: The silicon carbide ceramic impeller has high tensile and compressive strength, and can withstand large mechanical loads without breaking.

Based on the above performance and advantages, silicon carbide ceramic impellers are widely used in the mixing of liquid-solid and gas-solid mixtures in metallurgy, chemical industry, environmental protection and other fields. Especially in harsh environments such as high temperature and strong corrosion, the silicon carbide ceramic impeller can exert its excellent high temperature resistance, corrosion resistance and wear resistance, ensuring long-term stable operation of the equipment.

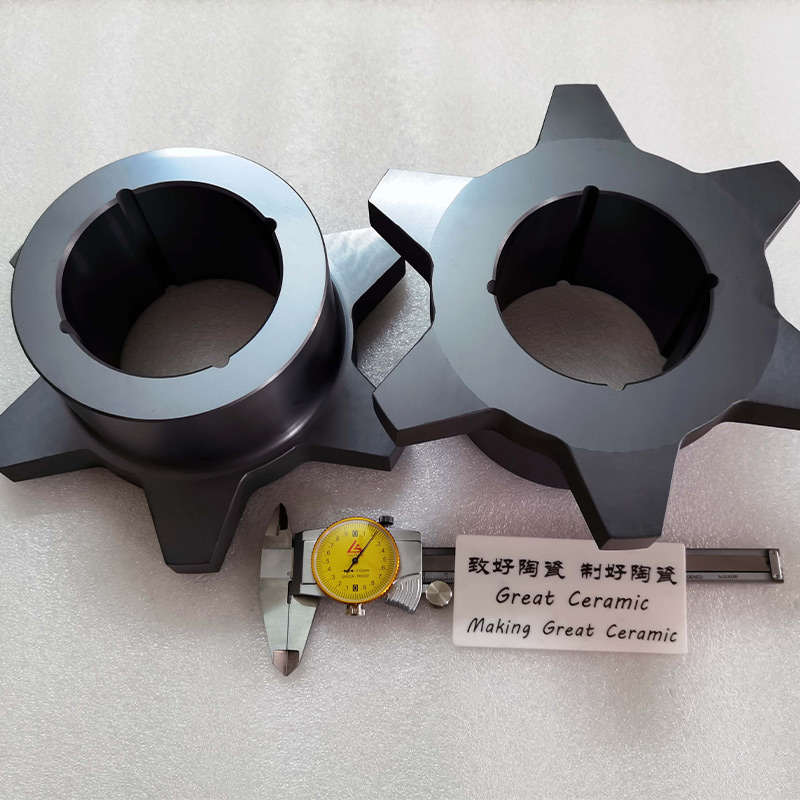

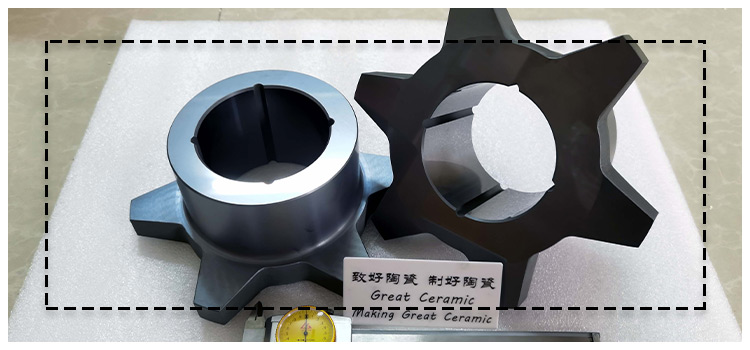

The Production Characteristics Of Silicon Carbide Impeller

- Can be customized with a maximum outer diameter of 500 mm and a height of 350 mm (current equipment capacity)

- The end face can be finely ground for the sealing surface, with an accuracy of 0.01mm

- The highest surface roughness Ra0.2um

- Strict dimensional inspection and surface fluorescence penetrant inspection are carried out at the factory

- Density greater than 3.14g/cm³

- The hardness is above 22GPa, very wear-resistant

- It can meet the requirements of food-grade medium transportation

Silicon Carbide Impeller Manufacturer

Great Ceramic has been engaged in precision technical ceramics for many years, and has rich experience in milling, grinding and polishing silicon carbide(SIC) ceramics. We can:

- Customized ceramic products according to requirements;

- Manufacturing very complex ceramic products;

- Achieve high dimensional accuracy;

- Fast response and delivery;

- Provide more professional services.

Great Ceramic can improve all tolerances according to the size and structure of precision advanced ceramic products. Great Ceramic is committed to ensuring that we only produce the highest quality precision ceramic parts that meet or exceed customer specifications.

Contact us to find out what we can do for you!

- We will reply to your message within 24 hours;

- We can provide you with technical consulting services;

- We support any number of product customization;

- We are happy to provide service for you.

Packing and Shipping

Great Ceramic’s SiC impeller will be packed in cartons and foam cotton before shipment to minimize damage during storage and transportation and maintain the original quality of the product.