Introduction

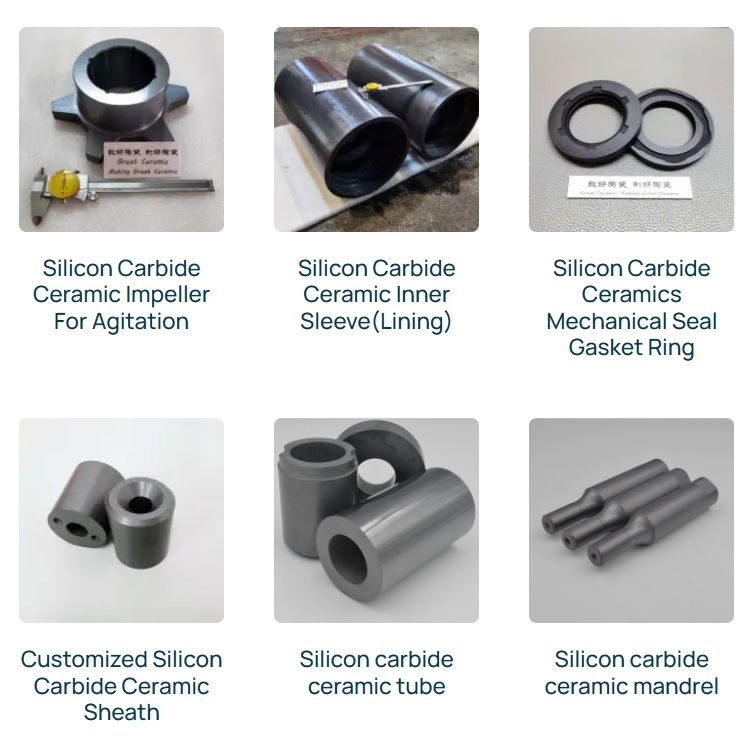

SiC ceramics are a type of structural ceramic material with excellent physical and chemical properties. They are widely used in aerospace, metallurgy, chemical, and energy industries. The sintering methods for SiC ceramics are mainly classified into four categories: pressureless sintering, reaction sintering, hot pressing, and hot isostatic pressing.

Pressureless Sintering

Pressureless sintering is a process of sintering SiC ceramics under normal pressure by adding sintering aids to enhance the bonding strength between powder particles. The advantages of pressureless sintering are that the equipment is simple and the production cost is low. It is suitable for the preparation of large-sized and complex-shaped parts. The disadvantages of pressureless sintering are that the sintering temperature is high, about 2000 °C or higher, and the sintering time is long, about 10-20 hours.

Reaction Sintering

Reaction sintering is a process of sintering SiC ceramics in which powder particles react with other substances to form new compounds, thereby promoting sintering densification. The advantages of reaction sintering are that the sintering temperature is low, about 1600 °C or so, and the sintering time is short, about 1-2 hours. The disadvantages of reaction sintering are that the types of sintering aids are limited, and the sintering process is prone to defects such as pores and cracks.

Hot Pressing

Hot pressing is a process of sintering SiC ceramics under pressure by heating to enhance the bonding strength between powder particles. The advantages of hot pressing are that the sintering temperature is relatively low, about 1800 °C or so, and the sintering time is short, about 1-2 hours. The disadvantages of hot pressing are that the equipment is complex and the production cost is high. It is suitable for the preparation of simple-shaped parts.

Hot Isostatic Pressing

Hot isostatic pressing is a process of sintering SiC ceramics under high temperature and pressure by heating to enhance the bonding strength between powder particles. The advantages of hot isostatic pressing are that the sintering temperature and pressure can be controlled, the sintering density is high, and the sintering defects are few. The disadvantages of hot isostatic pressing are that the equipment is complex and the production cost is high.

Comparison of Sintering Methods for SiC Ceramics

Table 1 summarizes the advantages and disadvantages of each sintering method for SiC ceramics.

| Sintering Method | Advantages | Disadvantages |

|---|---|---|

| Pressureless Sintering | Simple equipment, low production cost, suitable for the preparation of large-sized and complex-shaped parts | High sintering temperature, long sintering time |

| Reaction Sintering | Low sintering temperature, short sintering time, suitable for the preparation of small-sized and simple-shaped parts | Limited types of sintering aids, sintering process prone to defects |

| Hot Pressing | Relatively low sintering temperature, short sintering time, suitable for the preparation of simple-shaped parts | Complex equipment, high production cost |

| Hot Isostatic Pressing | Controllable sintering temperature and pressure, high sintering density, few sintering defects | Complex equipment, high production cost |

Development Trends of Sintering Methods for SiC Ceramics

With the advancement of science and technology, the sintering methods for SiC ceramics are also constantly developing. The future development trends of sintering methods for SiC ceramics mainly include the following aspects:

- Low-temperature sintering: Low-temperature sintering can reduce energy consumption, reduce production costs, and promote the industrialization of SiC ceramic products.

- High-performance sintering: By improving the sintering process, the performance of SiC ceramics can be improved, such as high-temperature strength, wear resistance, and corrosion resistance.

- Complex-shaped sintering: The development of sintering methods suitable for the preparation of complex-shaped SiC ceramics.

Conclusion

Sintering methods for SiC ceramics are an important process for the preparation of SiC ceramics. Different sintering methods have different advantages and disadvantages. The appropriate sintering method should be selected according to specific needs. In the future, the sintering methods for SiC ceramics will develop in the direction of low-temperature sintering, high-performance sintering, and complex-shaped sintering.