Technical Ceramic Laser Cutting

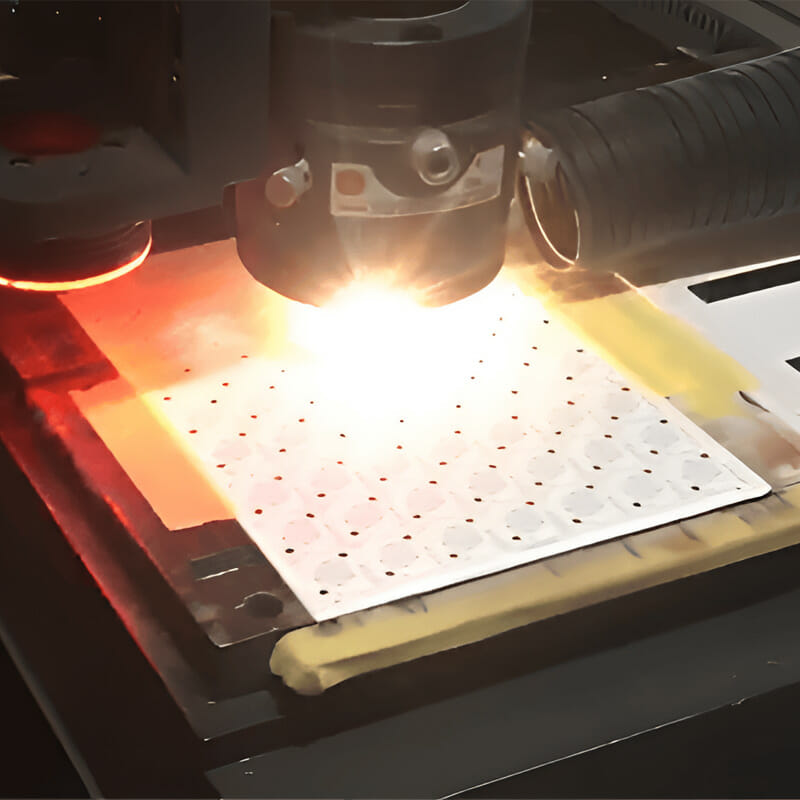

Ceramic laser cutting uses high-energy-density laser beams to irradiate ceramic materials, causing the ceramic materials to quickly melt, vaporize or evaporate in a very short period of time, thereby achieving the cutting of ceramic materials. It has the advantages of good cutting quality, high cutting efficiency, small heat-affected zone, suitable for processing complex graphics and curves, and can achieve mass production.

Ceramic Laser Cutting Principle

The principle of ceramic laser cutting is to utilize the interaction between the laser beam and the ceramic material. When the laser beam irradiates the surface of the ceramic material, a high-temperature, high-pressure melting zone will be formed on the surface of the ceramic material. Due to the high energy density of the laser beam, the melted zone evaporates rapidly in a very short time, thereby achieving cutting of ceramic materials.

Ceramic Laser Cutting Customization

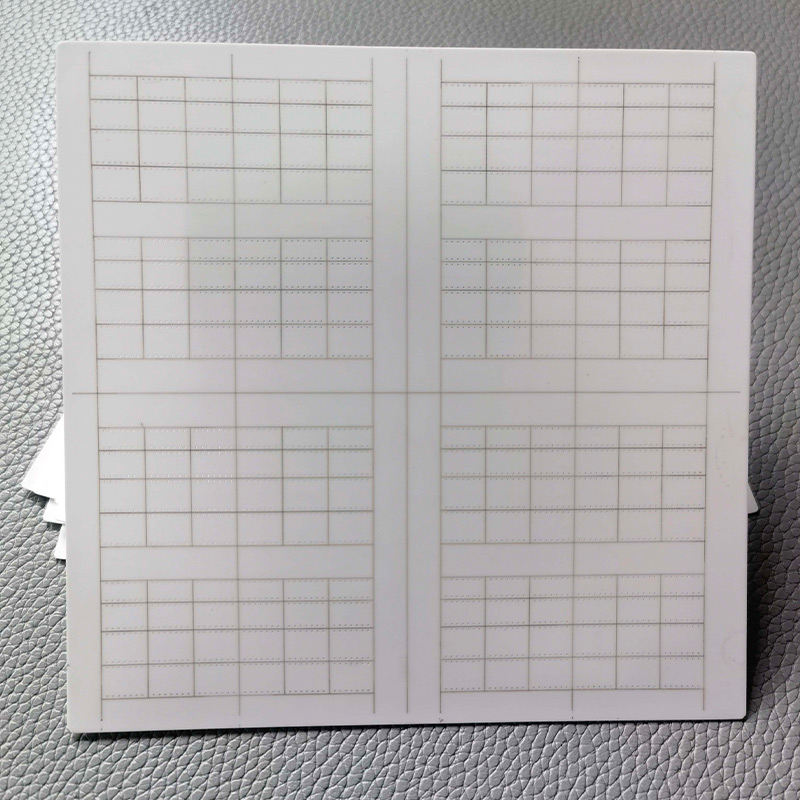

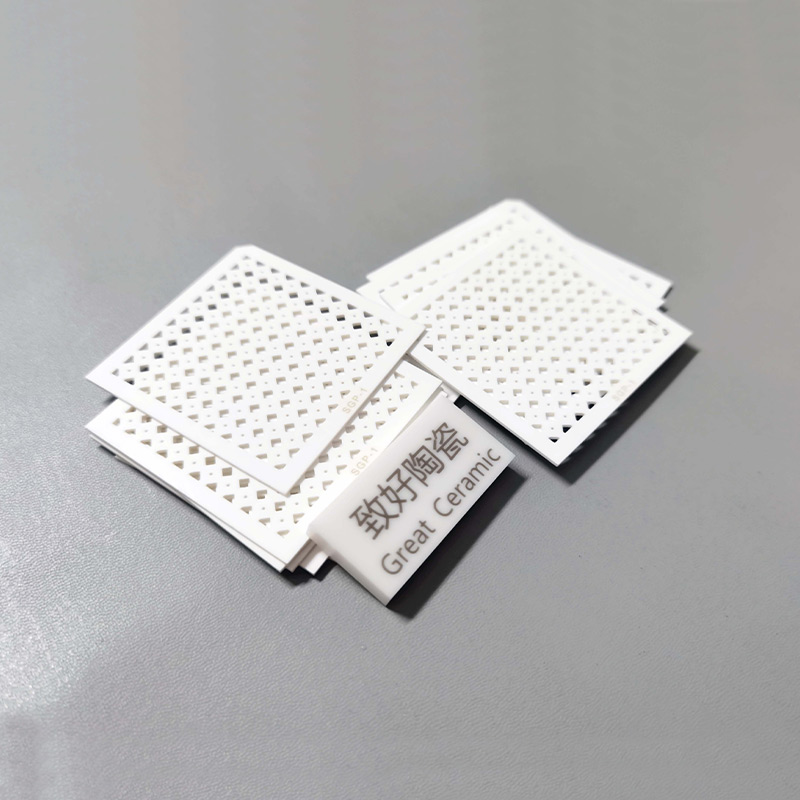

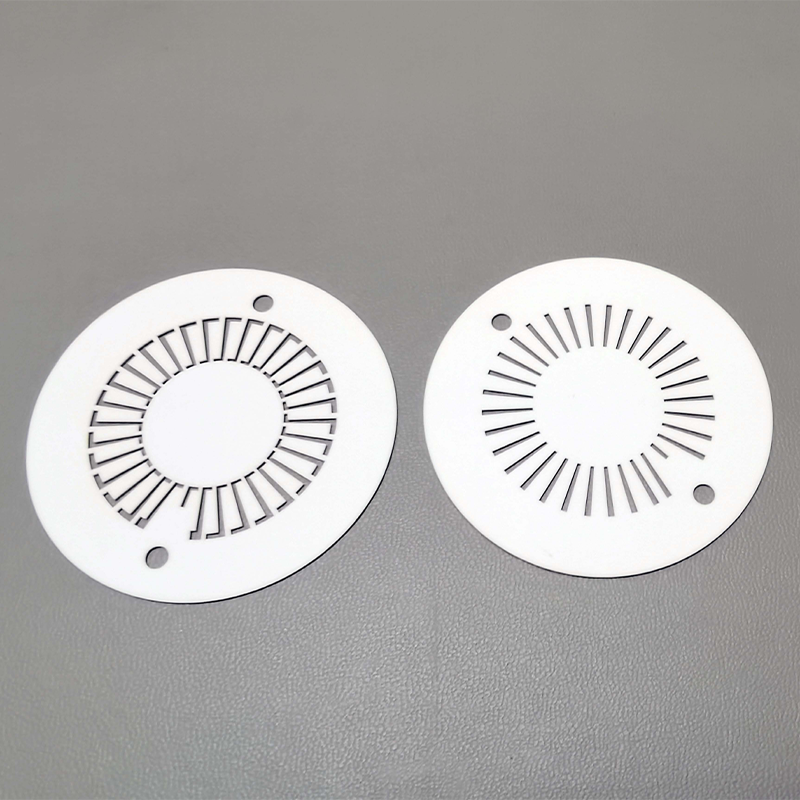

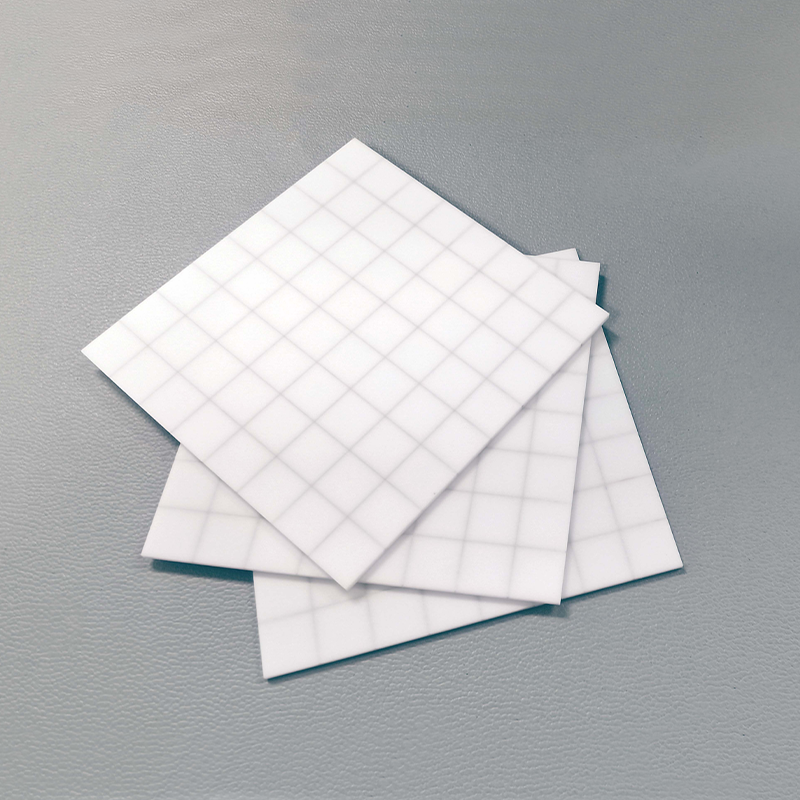

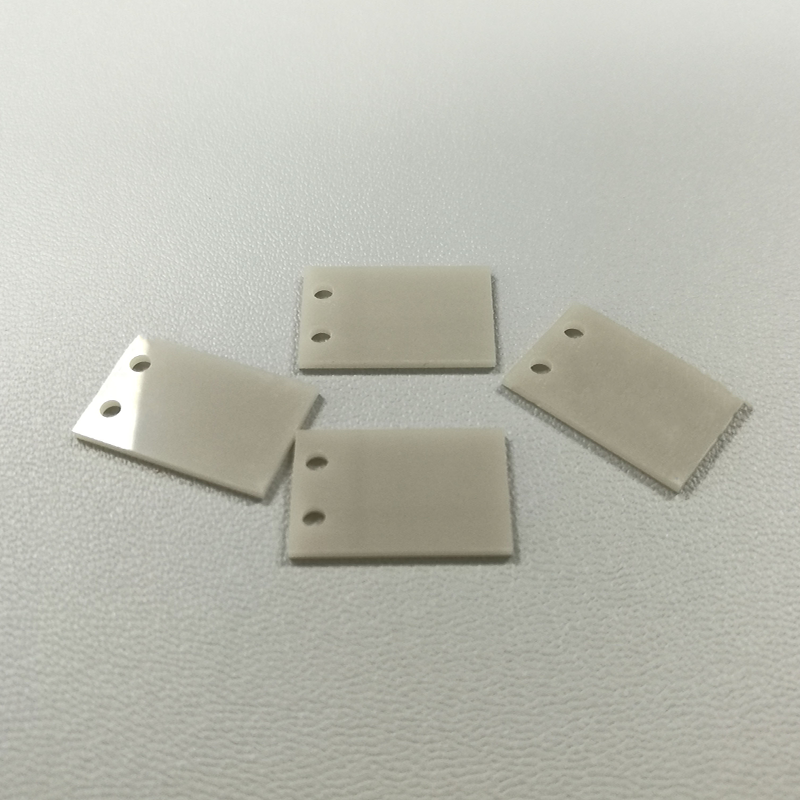

Ceramic laser cutting can process complex patterns, penetrating grooves and holes, and pre-processed dividing lines for breaking off on ceramic substrates. Moreover, we can provide customized processing services according to customers' technical requirements and drawings.

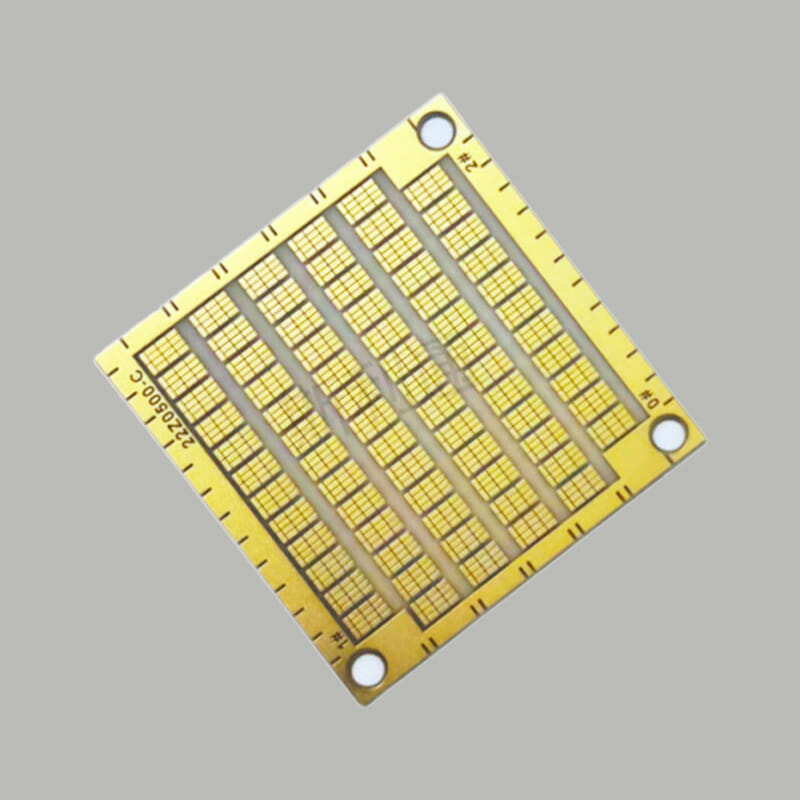

Aluminum Nitride Substrate Laser Cutting

Alumina Substrate Laser Cutting

Alumina Substrate Laser Cutting Grooves

Laser Cutting Insulating Gasket

Beryllium Oxide Laser Cutting

AlN Insulating Gasket

Ceramic Laser Processing Capability

- Max Processing Range: 250×250mm

- Max Processing Thickness: 2.0 (AL2O3), 3.0 (ALN), 1.0 (ZrO2),

- Min Aperture: 0.02mm

- Min Distance Between Hole And Edge: 0.2mm

Laser Cutting Tolerance Reference List

The table below is for reference only. Usually, we will make products according to the drawings provided by customers.

| Items | Ceramic Laser Cutting | ||

| General | Precision | ||

| Length Tolerances | T≤0.645 | +0.20/-0.05 | +0.15/-0.05 |

| 0.635<T≤1.0 | +0.25/-0.10 | +0.20/-0.05 | |

| 1.0<T≤1.2 | +0.30/-0.10 | +0.25/-0.10 | |

| Thickness Tolerances | ±10% Min:±0.05 | ±7% Min:±0.05 | |

| Distance Tolerances Between Snap-lines Or Holes | ±0.05 | ±0.05 | |

| Hole Diameter Tolerances | T≤0.645 | ±0.075 | ±0.05 |

| T>0.635 | ±0.1 | ±0.075 | |

| Tolerance Of Distance From Edge To Snap-line Or Hole | T≤0.645 | +0.15/-0.05 | +0.15/-0.05 |

| 0.635<T≤1.0 | +0.20/-0.05 | +0.20/-0.05 | |

| 1.0<T≤1.2 | +0.25/-0.10 | +0.25/-0.10 | |

| Overall Camber | 0.3% Min:0.05 | 0.25% Min:0.05 | |

| Parallelism/Verticality | 0.3% longest edge size | 0.2% longest edge size | |

Contact US

Learn about ceramic substrate metallization