Zirconia Ceramic Parts

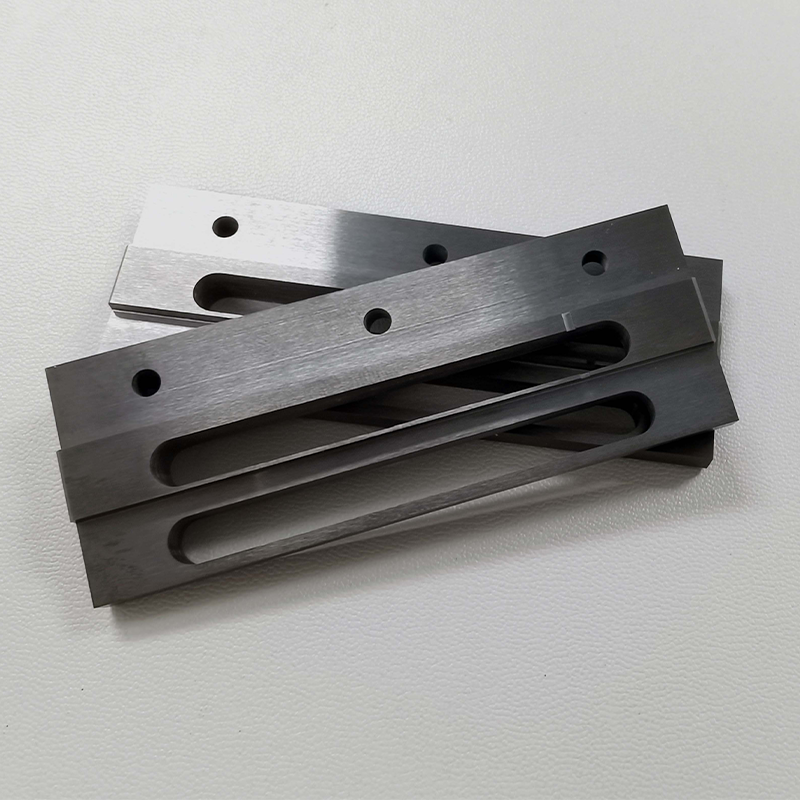

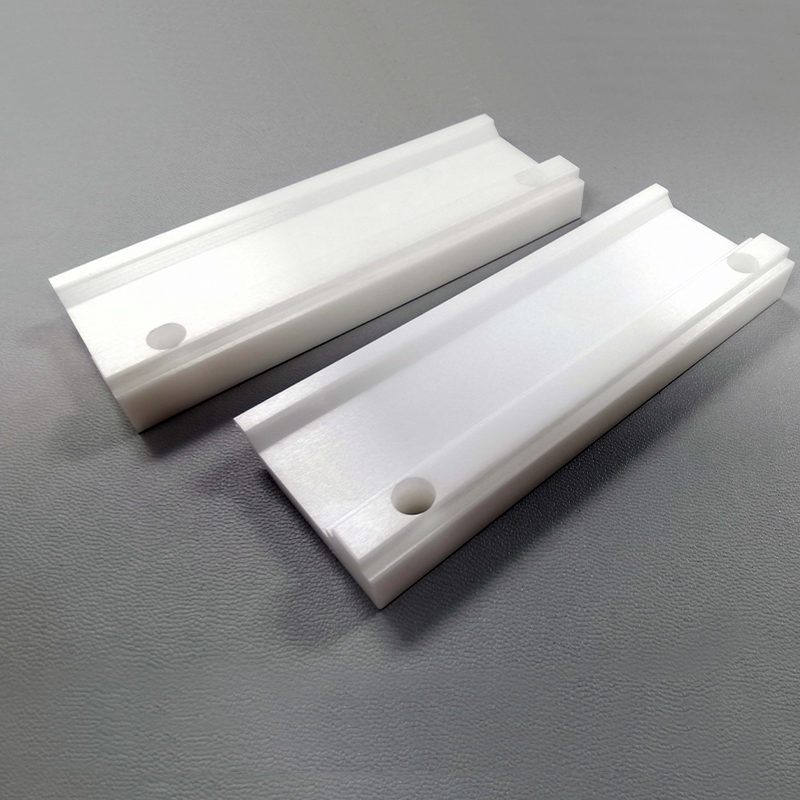

Zirconia ceramics (components) have high strength, high hardness, excellent wear resistance and corrosion resistance, as well as good toughness and low thermal conductivity, making them suitable for precision machining and high-performance applications.

Types of Zirconia Ceramics

Zirconia ceramics can change their composition or color according to different industrial needs, and each type has different performance characteristics and application scenarios. The following are the common types of zirconia ceramics we sell:

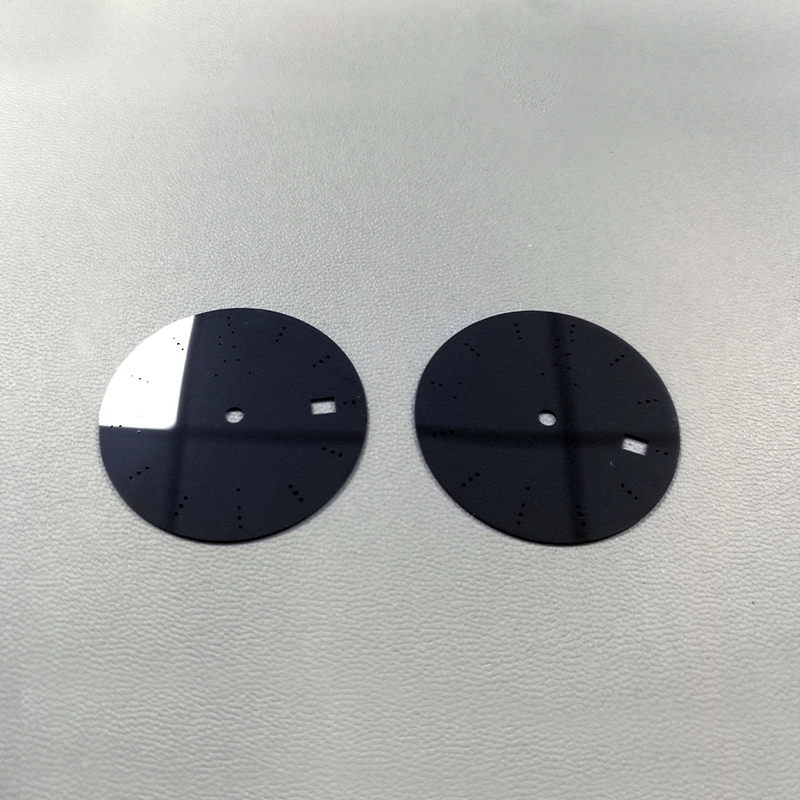

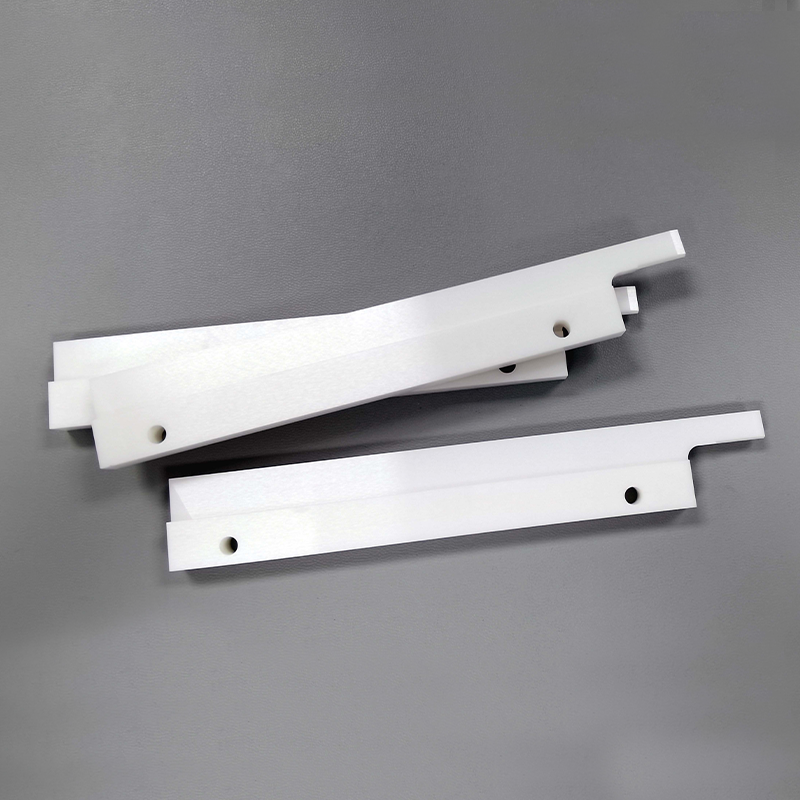

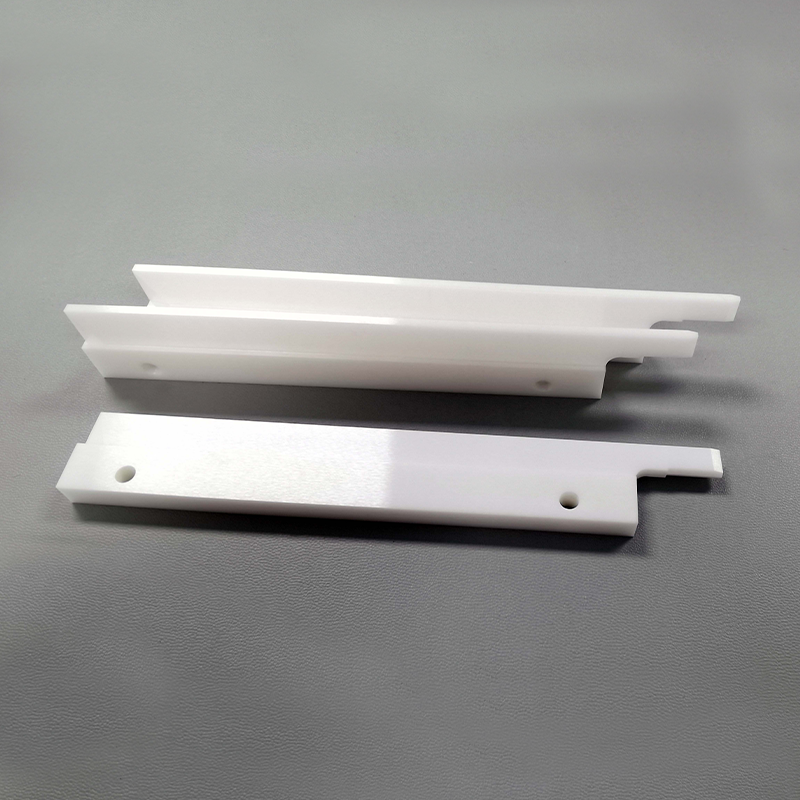

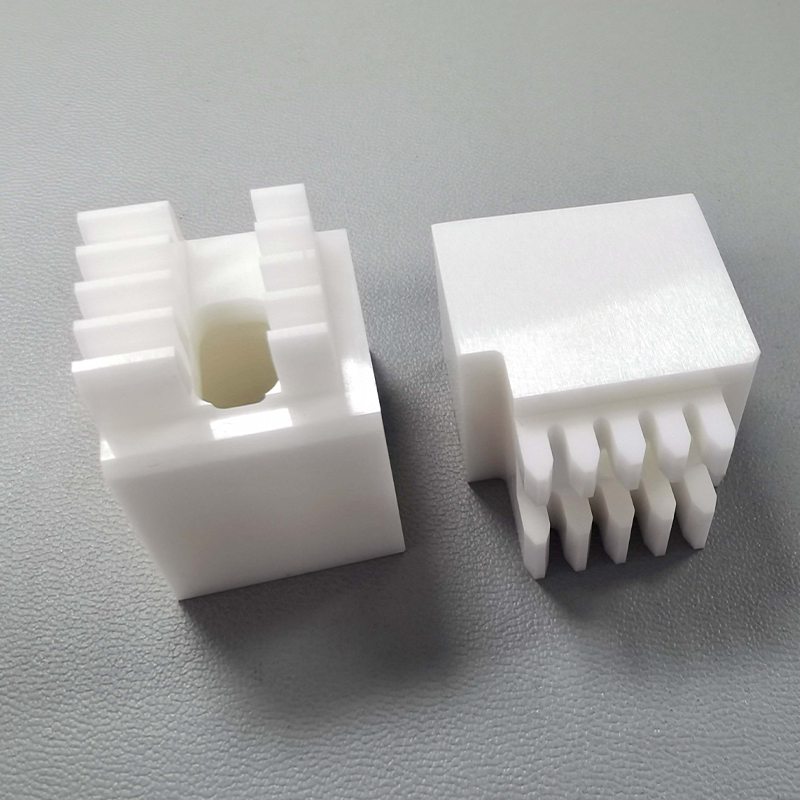

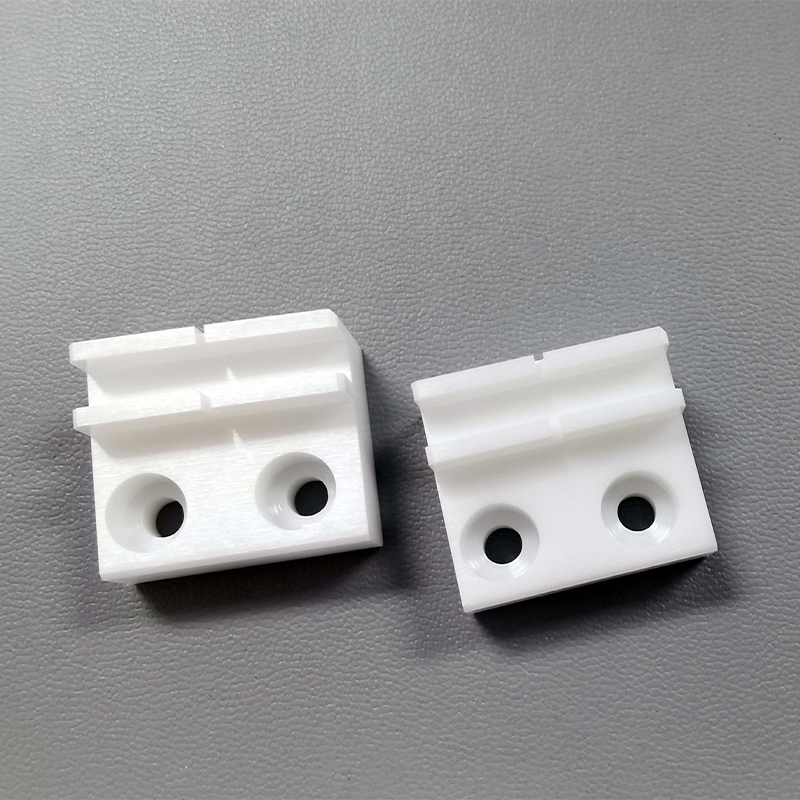

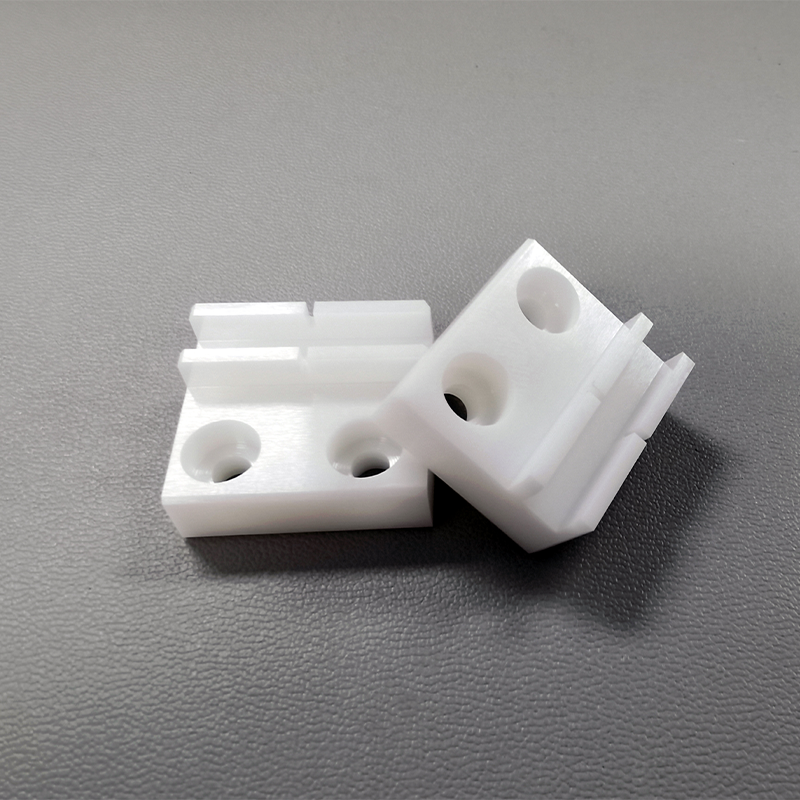

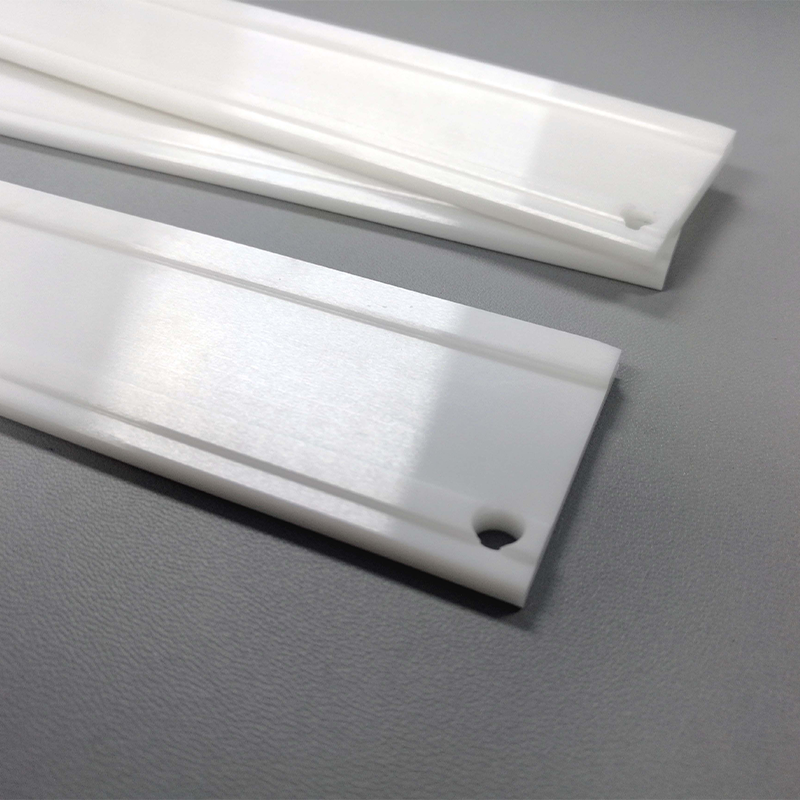

Custom machined zirconia ceramic parts

Great Ceramic is a professional manufacturer of zirconia ceramic parts (components), providing customized machining, OEM and other services. Its products include ceramic materials, ceramic plates, ceramic tubes, ceramic rods, ceramic sleeves, ceramic parts, etc.