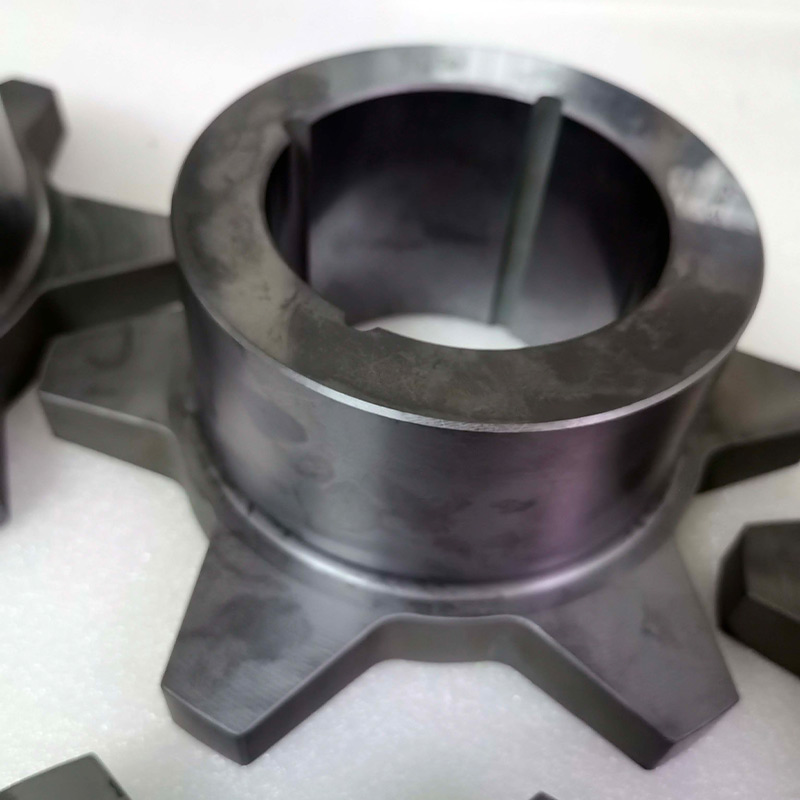

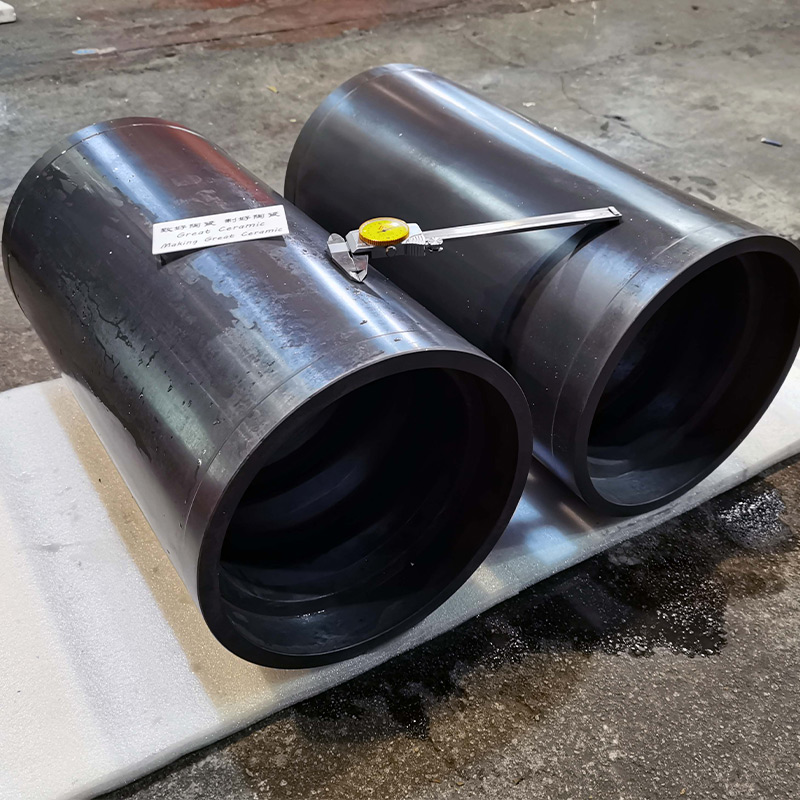

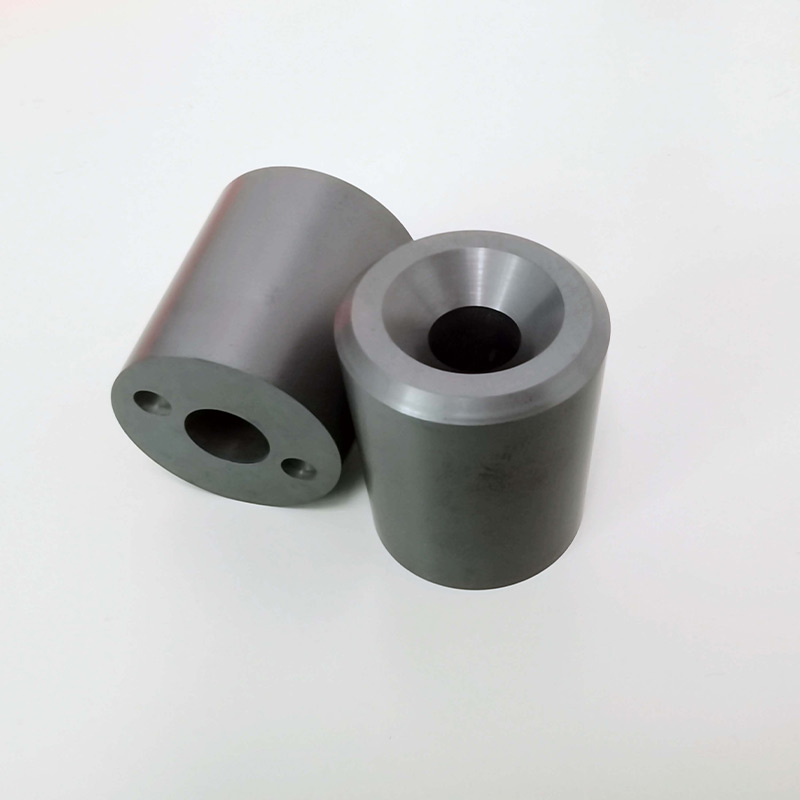

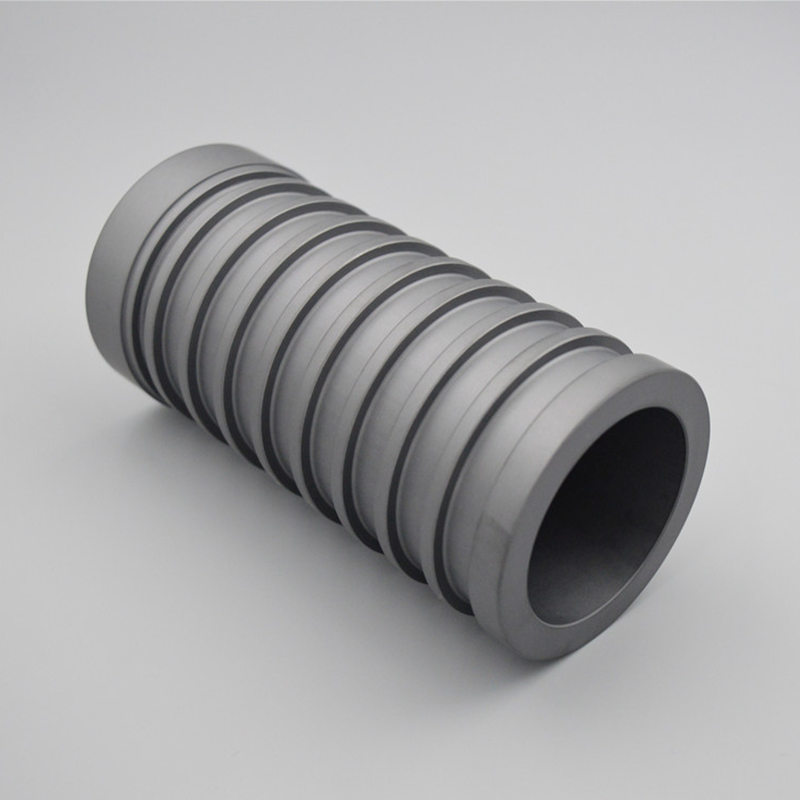

Silicon Carbide Ceramic Parts & Components

Silicon carbide ceramic (SiC) components have the characteristics of high hardness, high temperature resistance, corrosion resistance, good thermal conductivity and low thermal expansion coefficient. It also has oxidation resistance, electrical insulation and high mechanical strength, and can work stably for a long time in harsh environments.

Uses of Silicon Carbide Ceramics

Silicon carbide ceramics (SIC) are widely used, mainly due to their excellent wear resistance, high temperature resistance, corrosion resistance and high strength. The following are some of the main applications of SIC ceramics:

Silicon Carbide Suppliers

Great Ceramic is a leading supplier of silicon carbide ceramics, providing customized processing, OEM and other services. Its products include silicon carbide crucibles, silicon carbide plates, silicon carbide bushings, silicon carbide rods, silicon carbide ceramic parts, etc.