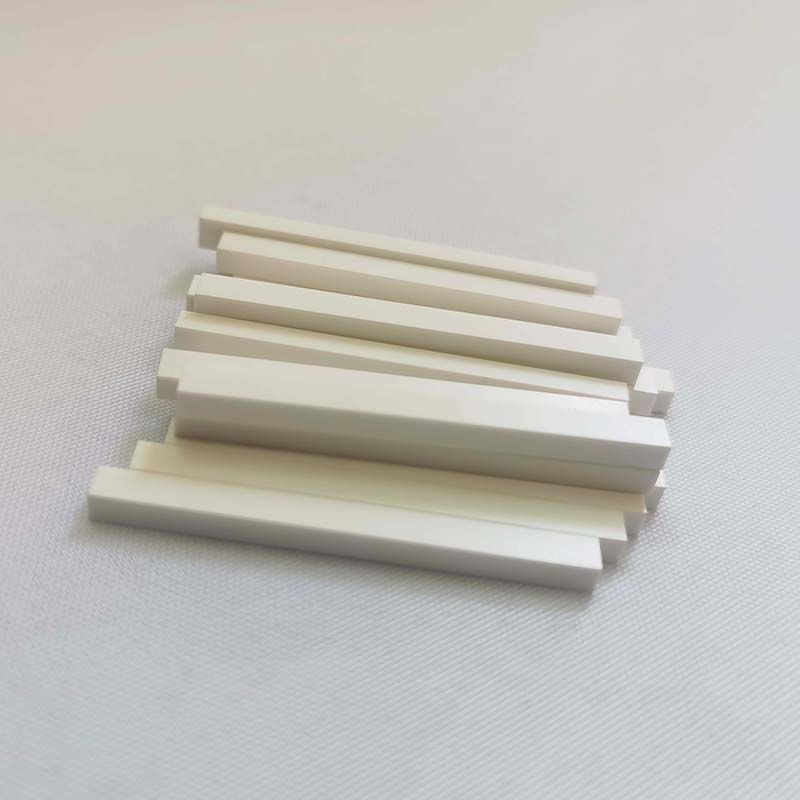

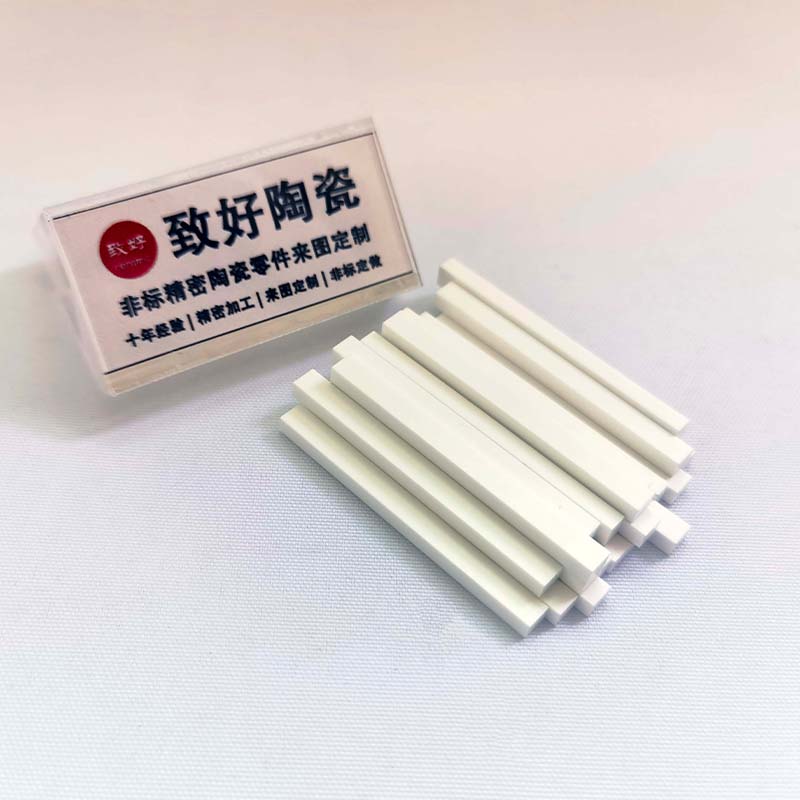

Zirconium Oxide Toughened Alumina (ZTA)

Zirconium Oxide Toughened Alumina (ZTA) is a composite material made from alumina and zirconia. It combines the outstanding characteristics of both materials. Compared to conventional alumina, ZTA possesses superior hardness, higher flexural strength, and similar density.

ZTA Advantage

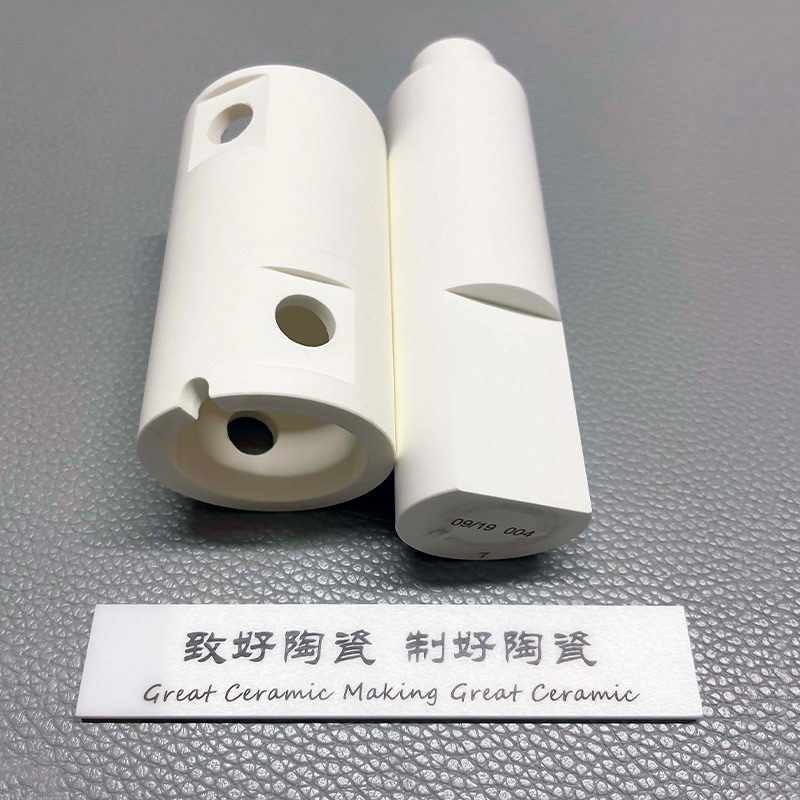

- Stronger than Steel: ZTA has bending strength comparable to steel for demanding applications where traditional materials are brittle.

- Toughness means elasticity: Unlike other brittle ceramics, ZTA's zirconia inclusions act as tiny barriers, absorbing and dissipating energy, preventing catastrophic cracks.

- Extremely Corrosion Resistant: ZTA has excellent chemical and high temperature resistance, allowing it to thrive in harsh environments where metals would yield.

Good friction properties: Low friction and wear resistance make ZTA the first choice for applications requiring smooth operation and extended service life.