Silicon Nitride Parts & Components

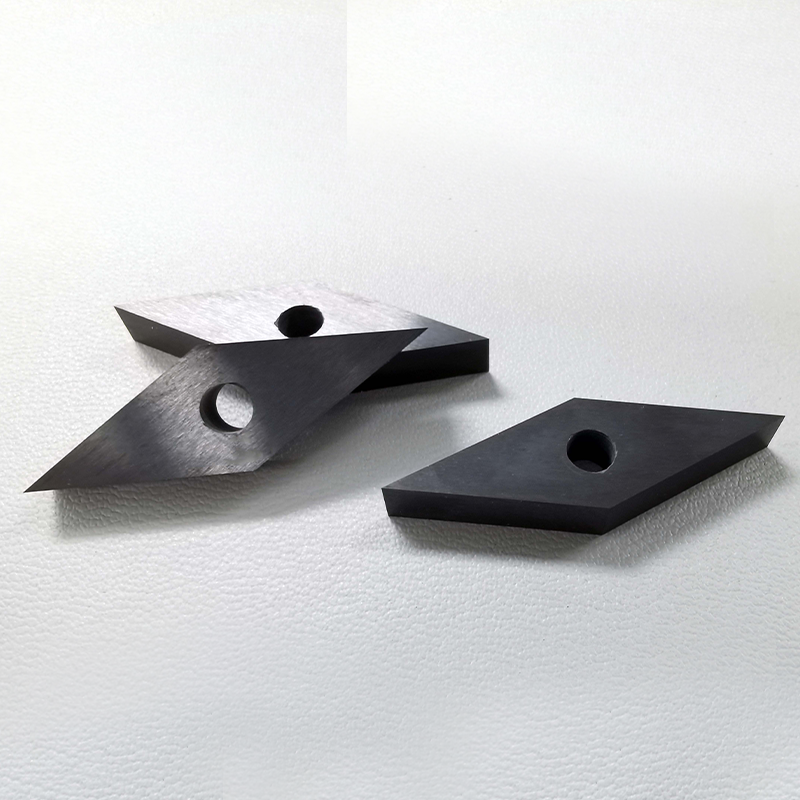

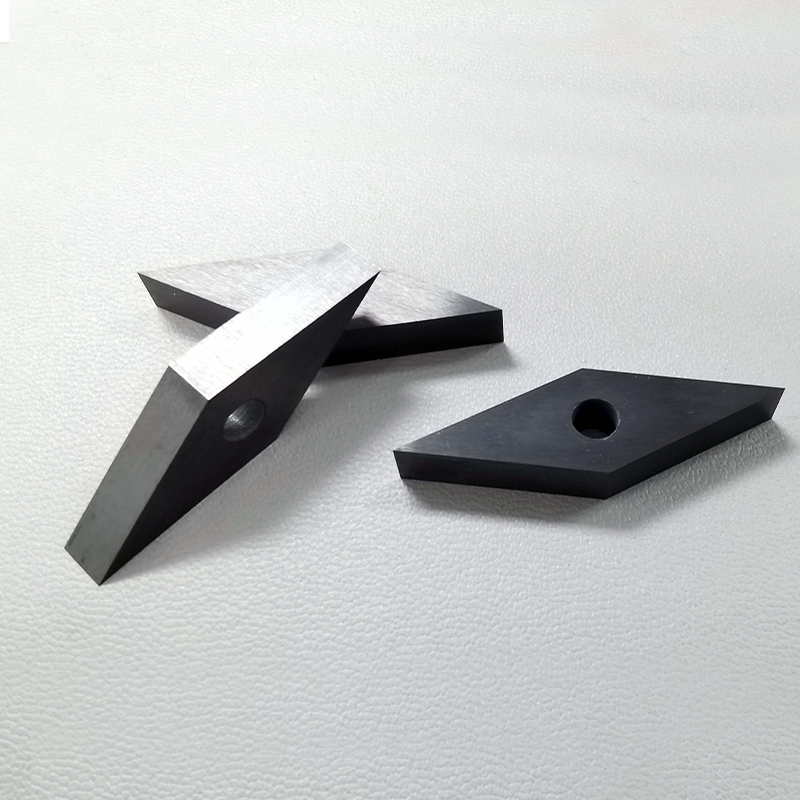

Silicon nitride materials (Si3N4) have high strength, high hardness, high temperature resistance, wear resistance, thermal shock resistance and excellent chemical stability, and are widely used in aerospace, automobile, electronics and other fields.

Silicon Nitride Materials Uses

Parts made of silicon nitride (Si₃N₄) ceramic materials are widely used in the following fields due to their high strength, high temperature resistance, wear resistance and thermal shock resistance:

Silicon Nitride Material Manufacturers

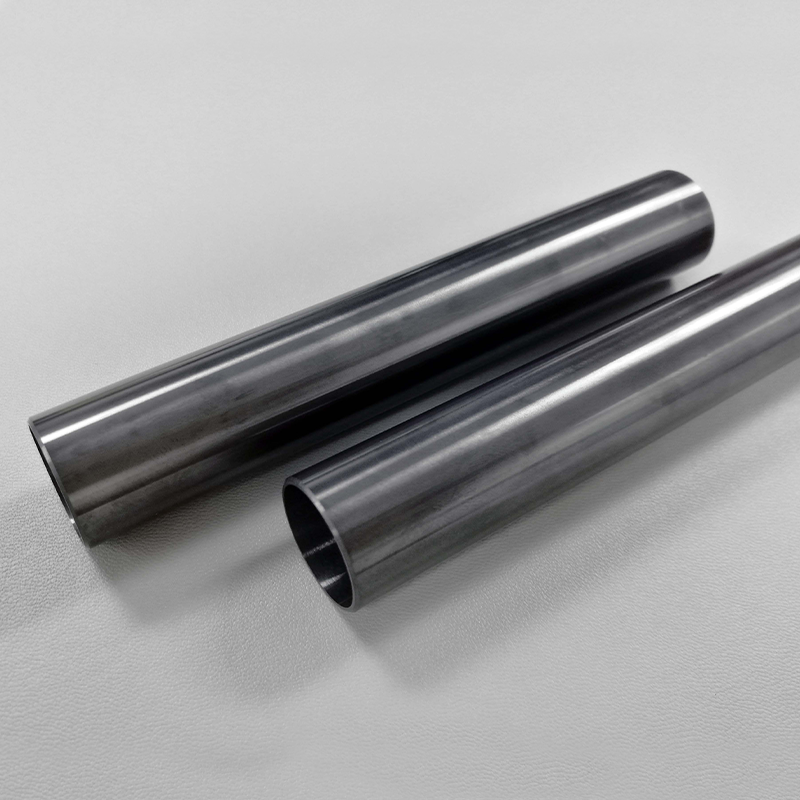

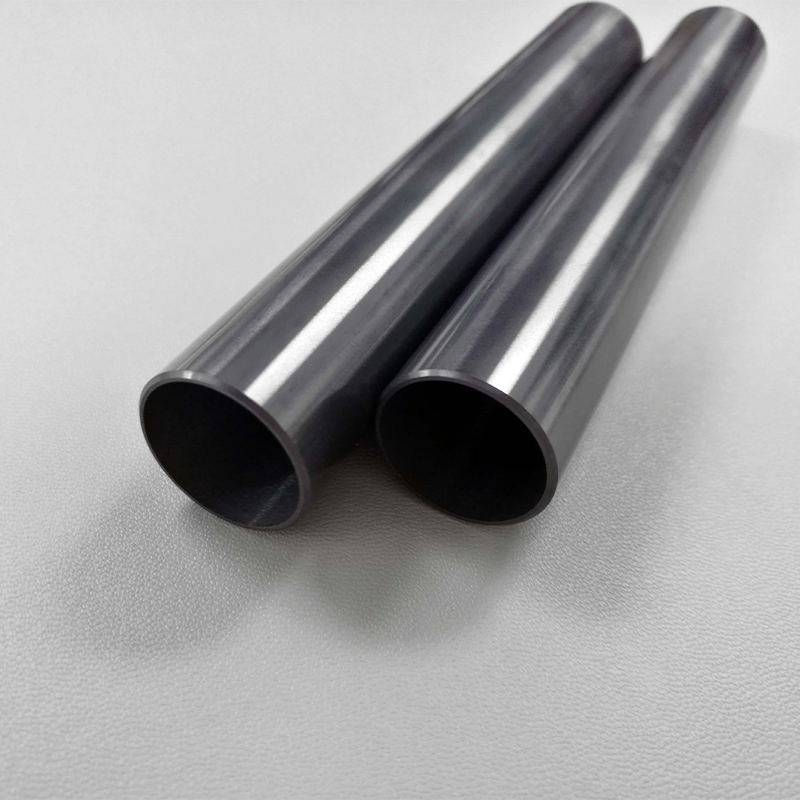

Great Ceramic is a professional manufacturer of silicon nitride ceramic materials parts (components), providing customized machining, OEM and other services. Its products include ceramic materials, ceramic plates, ceramic tubes, ceramic rods, ceramic sleeves, ceramic parts, etc.