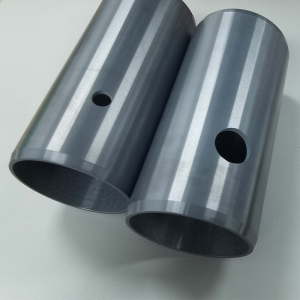

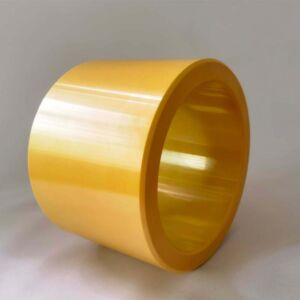

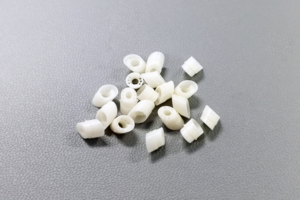

Macor Ceramic Machining

While in the past few years, our factory prides itself on a team of cutting-edge technologies, delivering excellence. To ensure your satisfaction, we contine to enhance production quality and effeciency, tailoring production according to your needs is fine, each product has met the standards required for professional certification. We make great efforts to achieve this win-win situation, skilled operation is our work, we survive by focusing on what customers want. Presently with the desire to expand our business, we’ve got decided to reach a broader audience. The world is our market – this macor ceramic machining will be supplied globally to West Asia, West Africa, Brazil, New Zealand, etc. Great Ceramic collaborates with many factories and qualitified team to provide expert and affordable macor ceramic machining worldwide. We will create a brilliant future in the production with our partners. You can contact us, and we will provide you a quotation up on receipt of the detailed needs. We are looking forward to cooperating with you and providing our best services for you, as well as our macor ceramic machining, Aluminum Oxide Ceramics Processing And Sales,Silicon Nitride Ceramics Processing And Sales.

Macor Ceramic Machining Boost Profit – Consider Other Products?

Macor Ceramic Machining Cut Down Cost – View Other Pages

More About Macor Ceramic Machining & Great Ceramic

Hello from Great Ceramic, have a look at the most trustworthy macor ceramic machining here! Great Ceramic has a long history and experience of providingmacor ceramic machining, which means we are capable and adept. Given our prolonged engagement in this market, we possess a substantial workforce, run a sizable factory, and uphold a high monthly production capacity. Our macor ceramic machining are trustworthy. Our macor ceramic machining are held to the highest quality standards due to our rigorous testing, adherence to standardized production methods, and comprehensive quality management efforts. Moreover, as a adept, we have plenty experience of macor ceramic machining and have gain great reputation. Our partnerships include countless collaborators from numerous countries. Our primary sales regions reach virtually every part of the world. We always believe that your request is our command!If you are looking for a trusted companion, consider us right now!