- Home

- Technical Ceramics Category And Application

- Magnesium Oxide Stabilized Zirconia Ceramic Sleeves

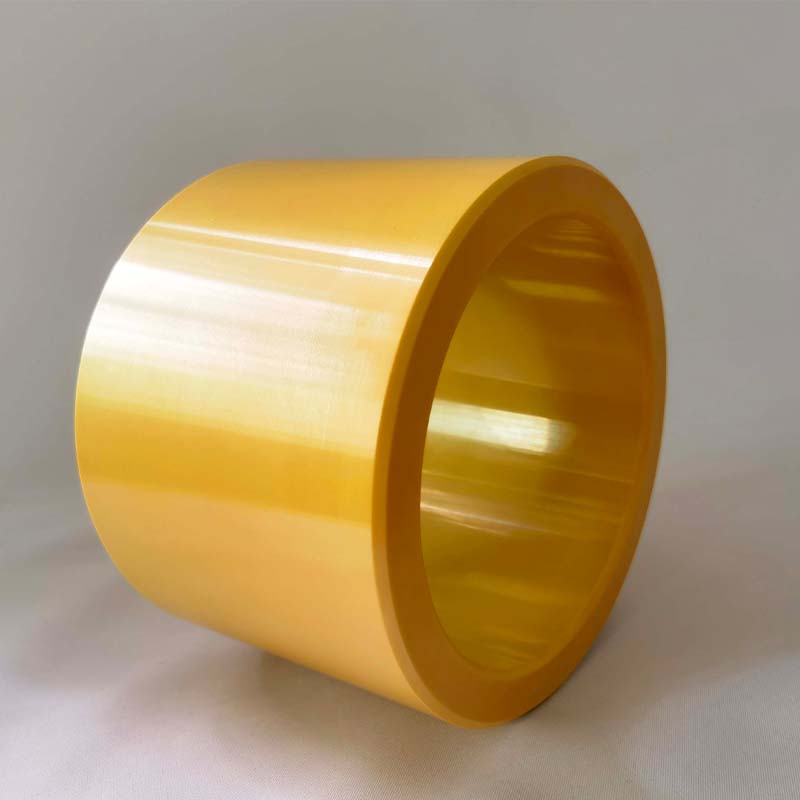

Magnesium Oxide Stabilized Zirconia Ceramic Sleeves

- Customizable

- Unmatched Wear Resistance

- Superior Strength

- Exceptional Thermal Shock Resistance

- Corrosion Resistance

- Low Thermal Conductivity

What are Mg-PSZ ceramic sleeves?

The Magnesium Oxide Stabilized Zirconia Ceramic Sleeves exhibit high strength, toughness, and wear & corrosion resistance. The magnesium oxide addition stabilizes the high-temperature tetragonal zirconia phase and prevents transformation to the room temperature stable monoclinic phase. This results in a product with high strength and corrosion resistance.

Ceramic Sleeves Performance Description

- Unmatched Wear Resistance: Mg-PSZ ceramic sleeves exhibit wear resistance 5-10 times higher than steel and significantly outperform other ceramics like alumina. This translates to extended component life, reduced maintenance downtime, and cost savings.

- Exceptional Strength: With a flexural strength surpassing most metals, Mg-PSZ sleeves withstand high loads and pressures without compromising integrity. This ensures reliable operation in even the most challenging environments.

- Impregnable Corrosion Barrier: Mg-PSZ ceramics are virtually immune to chemical attack, making them ideal for handling aggressive fluids, gases, and abrasive materials. Their inherent self-lubricating properties further minimize friction and wear.

- Thermal Stability: Mg-PSZ sleeves maintain dimensional stability and performance across a wide temperature range, from cryogenic to high-heat applications. This versatility expands their potential across diverse industries.

Industry Applications

These ceramic sleeves are widely used in various industries due to their excellent wear and corrosion resistance, as well as their high mechanical strength and biocompatibility. Some typical applications include:

- Pump & Valve Components: Mg-PSZ sleeves excel in pump impellers, plungers, and valve seats, ensuring extended service life and reduced downtime in fluid handling systems.

- Wear Parts & Linings: Their exceptional wear resistance makes them ideal for lining chutes, hoppers, and wear plates in industries like mining, cement, and power generation.

- High-Precision Components: Mg-PSZ’s dimensional stability and low thermal expansion coefficient make them perfect for precision applications like bearings, bushings, and seals.

- Chemical & Medical Equipment: The inherent corrosion resistance and biocompatibility of Mg-PSZ find applications in various chemical processing and medical device components.

Why Choose Magnesium Stabilized Zirconia?

Magnesium Oxide Stabilized Zirconia Ceramic Sleeves are a high-performance solution for various industrial applications, offering exceptional durability, wear resistance, and chemical resistance. Their unique properties make them an ideal choice for a wide range of industries, including structural ceramics, bearings, and wear parts.

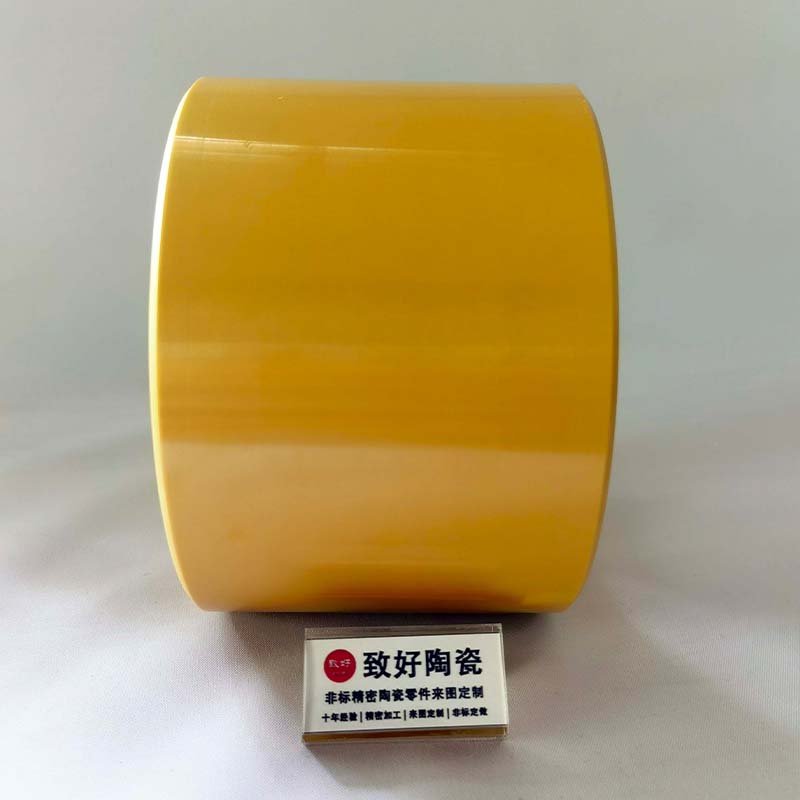

Zirconia Ceramics Supply Company

Great Ceramic has been engaged in the work of precision technical ceramics for many years, and has rich experience in the milling, grinding and polishing of Zirconia(ZrO2) Ceramics. We can:

- Make products according to the requirements of the drawings;

- Manufacturing more complex products;

- Achieve higher dimensional accuracy;

- Realize quick response and delivery;

- Provide more professional services.

Great Ceramic can improve all tolerances according to the size and structure of precision advanced ceramic products. Great Ceramic is committed to ensuring that we only produce the highest quality precision ceramic parts that meet or exceed customer specifications.

Packing and Shipping

Great Ceramic’s magnesium stabilized zirconia ceramic sleeves has been carefully processed to minimize damage during storage and transportation and maintain the quality of our products in the original state.