High-Temperature Co-fired Ceramic

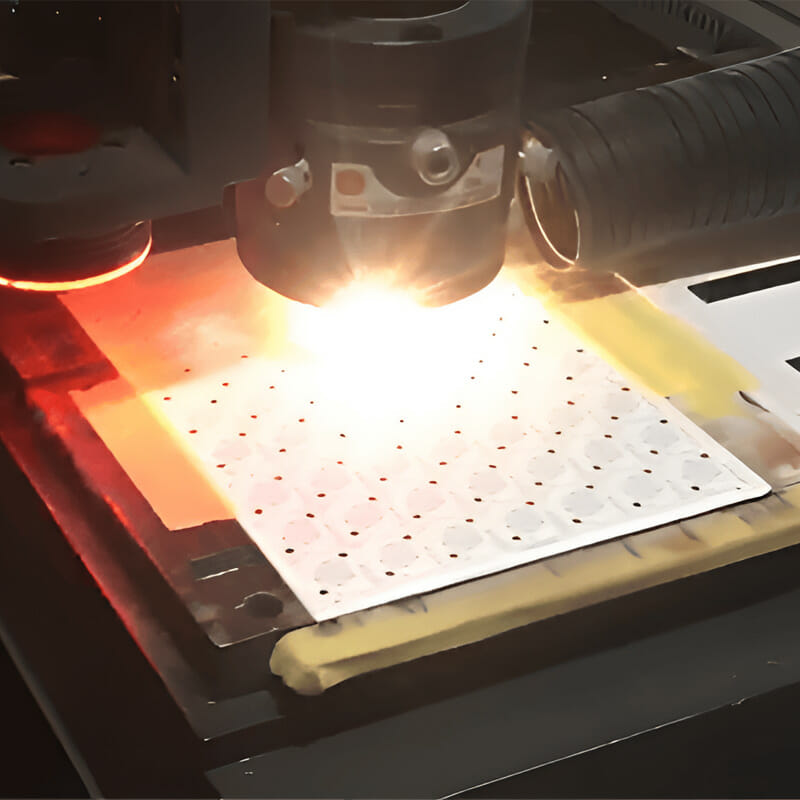

High-temperature co-fired ceramics (HTCC) mainly use aluminum nitride green ceramic tape and high melting point metal pastes such as tungsten, molybdenum and manganese as the main raw materials. The paste is printed on the green ceramic tape through screen printing to form a metal circuit. , and use through-hole filling to connect the upper and lower layers, and then perform multi-layer lamination and high-temperature sintering (the sintering temperature of alumina HTCC is above 1500°C, and the sintering temperature of aluminum nitride HTCC is above 1800°C), and finally electroplating , welding and other processes to form a monolithic structure of a three-dimensional wiring system, which has the advantages of corrosion resistance, high temperature resistance, long life, high efficiency and energy saving, uniform temperature, good thermal conductivity, and fast thermal compensation speed.

HTCC Product Applications

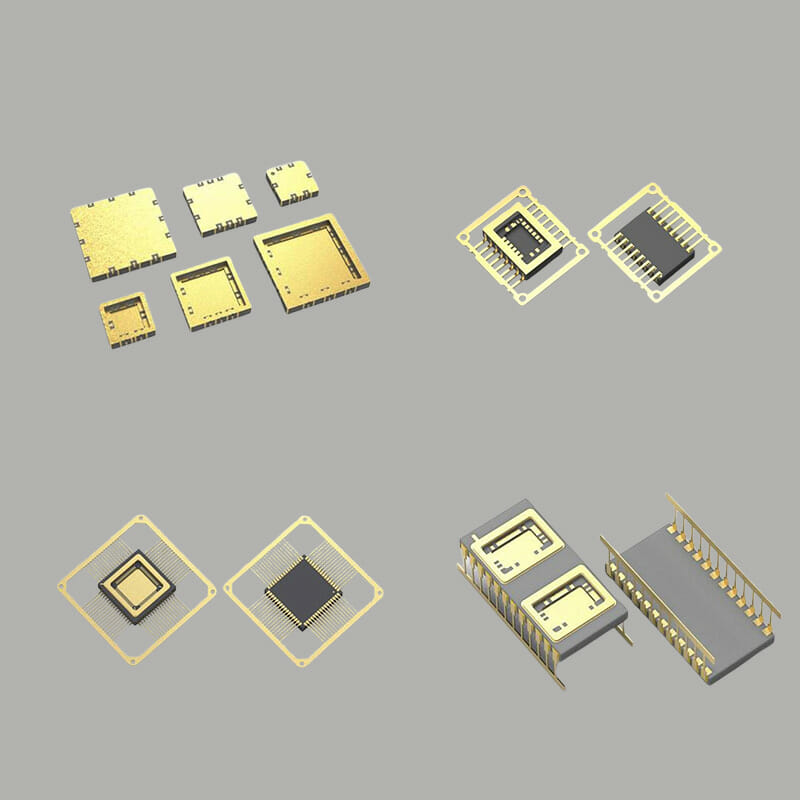

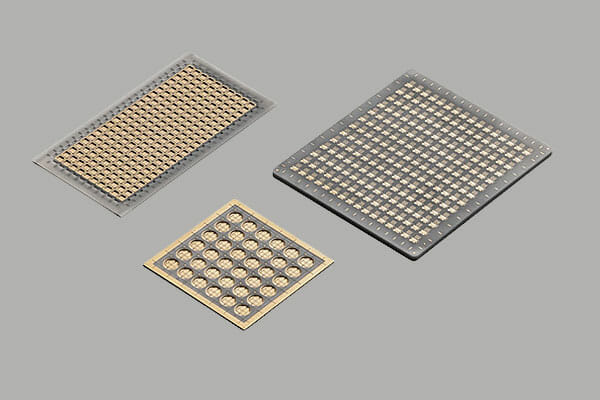

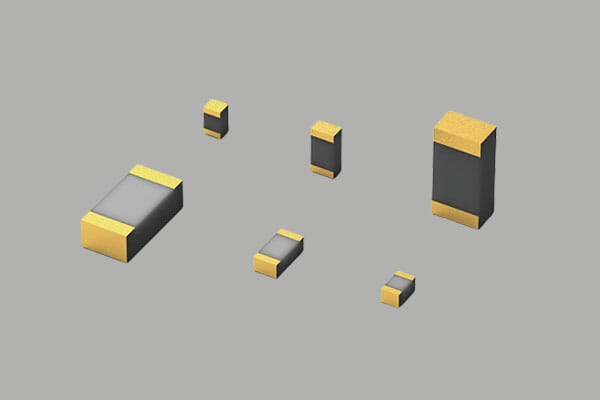

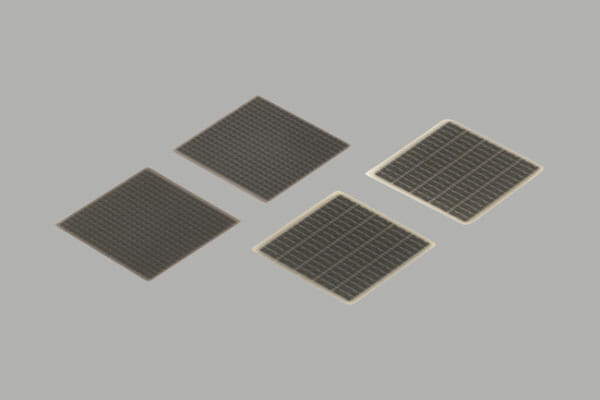

HTCC products mainly include ceramic multi-layer substrates, ceramic packaging shells, UVLED brackets, various heating sheets, etc. The products are mainly used for microwave device packaging, large-scale integrated circuit packaging, hybrid integrated circuit packaging, optoelectronic device packaging, LED chip packaging, Semiconductor packaging and other packaging fields.

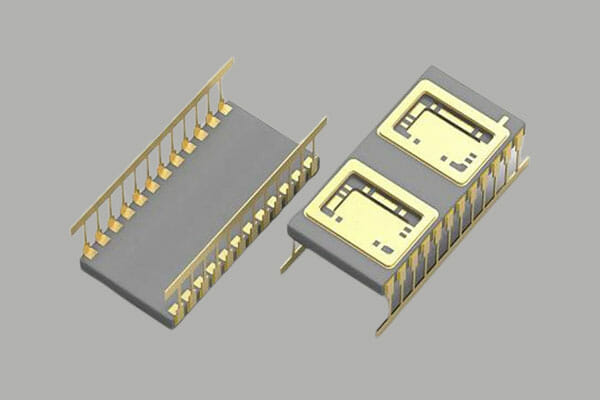

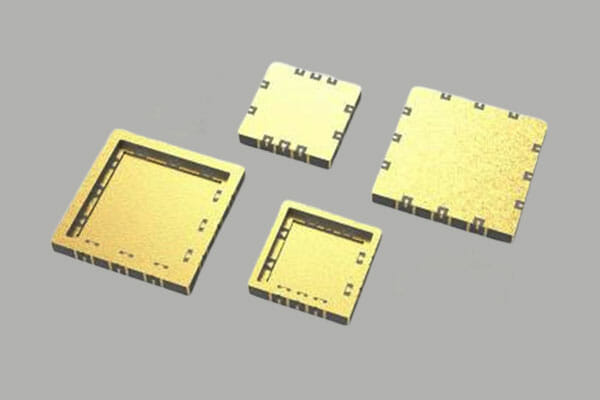

Ceramic Package Housing

Leadless Ceramic Package Housing

UVLED, VCSEL Bracket

Thermal Bridge

Optical Communication Module

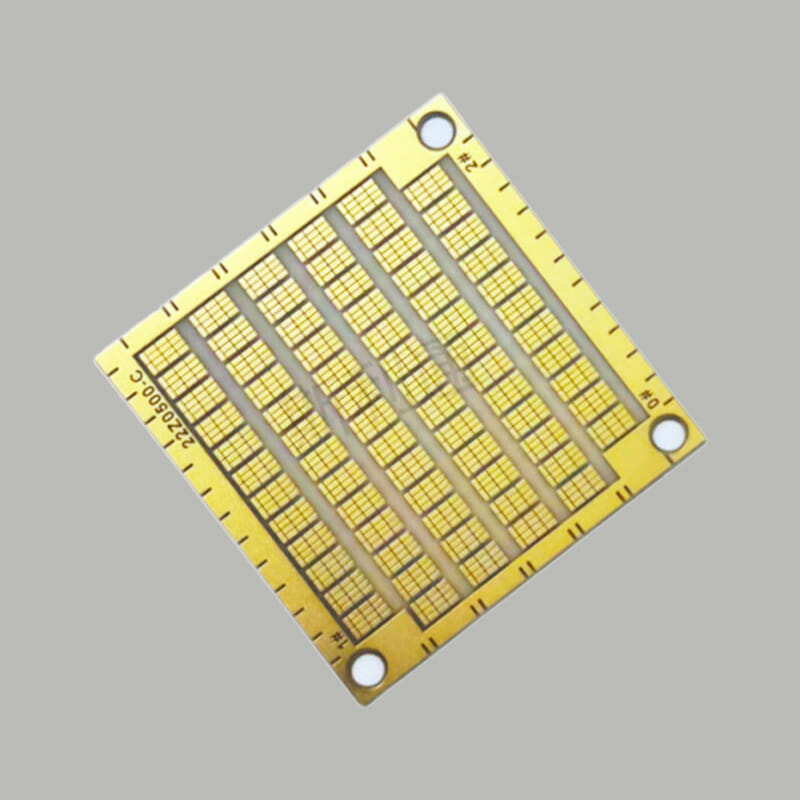

Ceramic Heating Element

HTCC Technical Indicators

- Green porcelain tile specifications: 152.4×152.4mm;

- Thickness range: 120~400um;

- Minimum line width for HTCC printing: 100um;

- HTCC printing minimum spacing: 100um;

- HTCC conductor printing thickness: 7~20um;

- Minimum diameter of through hole: 100um;

- Warpage: <3um/mm;

- Number of HTCC layers: 2~40 layers;

- Single layer thickness: 5 types including 100, 125, 150, 200, 250um.

Learn about laser processing of ceramic substrates

Learn about ceramic substrate metallization