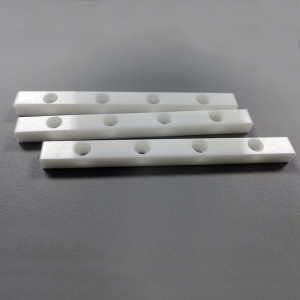

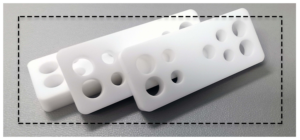

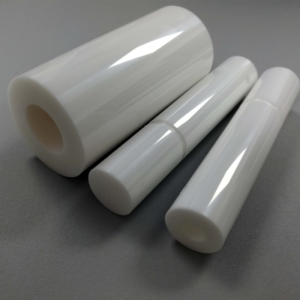

Ceramic Part

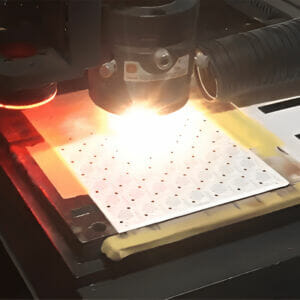

With our cutting-edge production facilities, we assure the production of high-quality goods, we also accept Customized Products order, our OEM-standard products successfully undergoes professional certification. We are eager to cooperate with foreign companies which care much on the high quality, budget-friendly prices, effective capability and superior service. The ceramic part will supply to all over the world, such as South Asia, South Africa, Mexico, Australia, etc. With a rich history spanning decades, our company is marked by innovative technologies, defining our professional approach. Great Ceramic collaborates with many factories and qualitified team to provide expert and affordable ceramic part worldwide. We are looking forward to cooperating with you and providing our best services for you, as well as our ceramic part, Aluminum Oxide Ceramics Processing And Sales,Silicon Nitride Ceramics Processing And Sales. We believe in: our goal is exceptional service, we adhering to the business philosophy of ‘customer first. Let us cooperate hand in hand to make a good future. Do contact us at any time you feel free.

Ceramic Part Boost Profit – Consider Other Products?

Ceramic Part Cut Down Cost – View Other Pages

More About Ceramic Part & Great Ceramic

Experience Great Ceramic firsthand, have a look at the most outstanding ceramic part here! Great Ceramic has a long history and experience of providingceramic part, which means we are capable and skilled. With a long history in this market, we have accumulated a substantial workforce, operate a spacious factory, and maintain a significant monthly production capacity. Our ceramic part are unique. Quality assurance is our top priority, and we achieve it through the implementation of strict testing standards, adherence to standardized production processes, and the practice of comprehensive quality management for our ceramic part. Moreover, as a skilled, we have a plethora of experience of ceramic part and have gain great reputation. We collaborate with abundant partners from various countries. Our primary sales regions encompass nearly every corner of the globe. We always believe that your request is our command!If you are looking for a industry-leading collaborator, consider us right now!