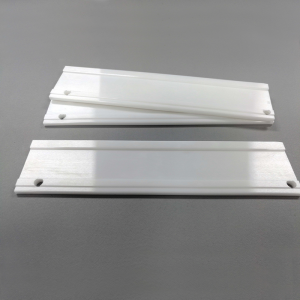

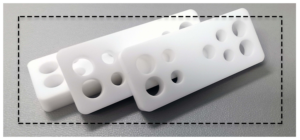

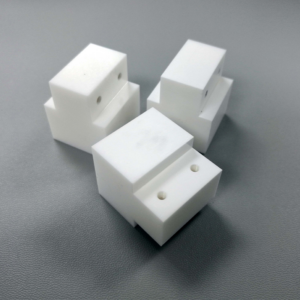

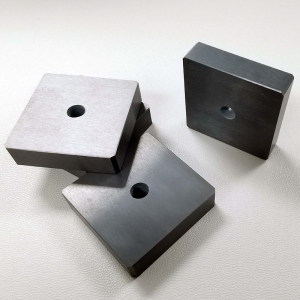

Ceramic Molding

We are looking forward to cooperating with you and providing our best services for you, as well as our ceramic molding, Aluminum Nitride Ceramics Processing And Sales,Silicon Carbide Ceramics Processing And Sales. Over the last few years, our company continues to lead the way cutting-edge technologies, professionalism is at the core of our success. We are committed to improving production quality and efficiency continually for your satisfaction feel free to tell us your special requests or concerns, all products have passed professional certification. Great Ceramic is dedicated into the market to providing premium ceramic molding and service all over the world. We welcome new and previous clients from all walks of lifestyle to get in touch with us for long term business relationships and mutual accomplishment! The world is our market – this ceramic molding will be supplied globally to West Asia, West Africa, Brazil, New Zealand, etc. The consumer fulfillment is our primary goal. We glance ahead on your pay a visit to and developing trustworthy and long-term standing relationship. We will continually strive to improve our service, innovation and integrity guide our path, trust builds our path to success.

Ceramic Molding Boost Profit – Consider Other Products?

Ceramic Molding Cut Down Cost – View Other Pages

More About Ceramic Molding & Great Ceramic

Step into the world of Great Ceramic, have a look at the most high-quality ceramic molding here! Great Ceramic has a long history and experience of providingceramic molding, which means we are skilled and experienced. Having been active in this market for an extended period, we possess a considerable number of employees, a spacious manufacturing facility, and a notable monthly production output. Our ceramic molding are trustworthy. We maintain the superior quality of our ceramic molding by upholding strict testing standards, following standardized production processes, and implementing a comprehensive quality management framework. Moreover, as a experienced, we have innumerable experience of ceramic molding and have gain great reputation. We maintain working relationships with a vast number of partners from different countries. Our main sales territories encompass nearly every part of the globe. We always believe that your request is our command!If you are looking for a worthy purchasing companion, consider us right now!