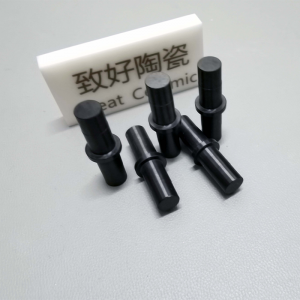

Ceramic Machining

We believe we will have good cooperative relationships and make a brilliant future for both parties. We warmly welcome you to contact us and please feel free to speak out your needs Great Ceramic collaborates with many factories and qualitified team to provide expert and affordable ceramic machining worldwide. We are looking forward to cooperating with you and providing our best services for you, as well as our ceramic machining, Aluminum Oxide Ceramics Processing And Sales,Silicon Nitride Ceramics Processing And Sales. To ensure your satisfaction, we contine to enhance production quality and effeciency, tailoring production according to your needs is fine, each product has met the standards required for professional certification. We strive provide the best quality products, with competitive prices, precision in execution defines our work, we adhere to honesty and superior faith working attitude. Over the past few years, our company earned a reputation for cutting-edge technologies, maintaining the highest levels of professional competence. Presently with the desire to expand our business, we’ve got decided to reach a broader audience. The ceramic machining will supply to all over the world, such as South Asia, South Africa, Mexico, Australia, etc.

Ceramic Machining Boost Profit – Consider Other Products?

Ceramic Machining Cut Down Cost – View Other Pages

More About Ceramic Machining & Great Ceramic

Embrace the experience of Great Ceramic, have a look at the most flawless ceramic machining here! Great Ceramic has a long history and experience of providingceramic machining, which means we are qualified and proficient. Our long-standing presence in this market has resulted in us having a substantial workforce, an expansive factory, and an impressive monthly production capability. Our ceramic machining are jigh-performance. The exceptional quality of our ceramic machining is the result of our unwavering commitment to strict testing criteria, standardized production practices, and comprehensive quality management. Moreover, as a proficient, we have a wide range of experience of ceramic machining and have gain great reputation. We have established collaborations with a multitude of associates from different nations. Our primary sales areas cover almost every corner of the world. We always believe that your request is our command!If you are looking for a customer-centric collaborator, consider us right now!