Aluminum nitride

Aluminum nitride (AlN) is a high-performance advanced ceramic material renowned for its exceptional thermal conductivity, outstanding electrical insulation, and excellent mechanical strength. The chemical formula for aluminum nitride is AlN, consisting of aluminum and nitrogen atoms bonded in a hexagonal crystal structure.

Unlike many ceramics, aluminum nitride ceramics combine high thermal conductivity with low dielectric constant, making them an ideal choice for applications where both efficient heat dissipation and electrical insulation are required.

With properties that surpass traditional ceramics like alumina in specific areas, AlN aluminum nitride has become an indispensable material in the semiconductor, electronics, aerospace, and power device industries.

Skip to

Advantages | Applications | Material Grades | Properties | Cases | Machining | FAQs | Related

Key Advantages of Aluminum Nitride

Aluminum nitride ceramic stands out due to a combination of superior physical and chemical characteristics that make it a better choice than many traditional materials.

Precautions

Aluminum nitride ceramics react chemically with liquids such as inorganic acids, strong bases, and water and dissolve slowly, so they cannot be directly immersed in such materials. However, aluminum nitride is resistant to most molten salts, including chlorides and cryolite.

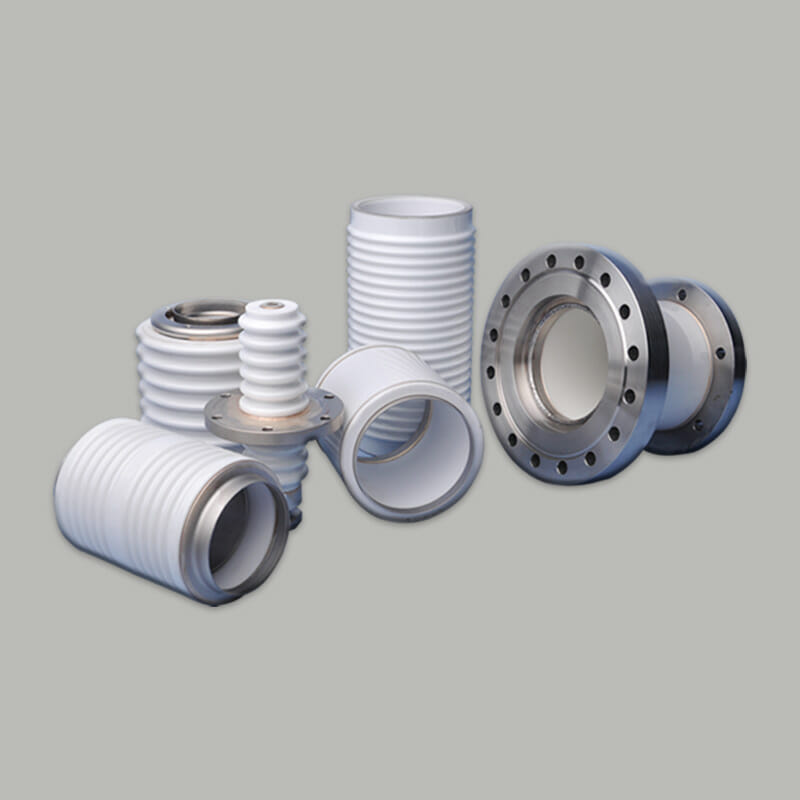

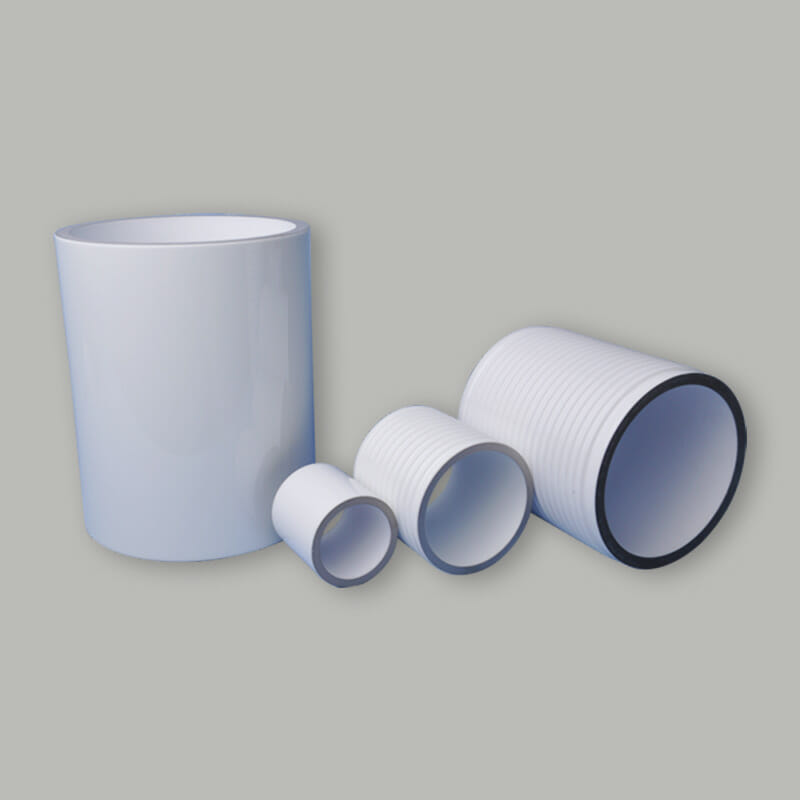

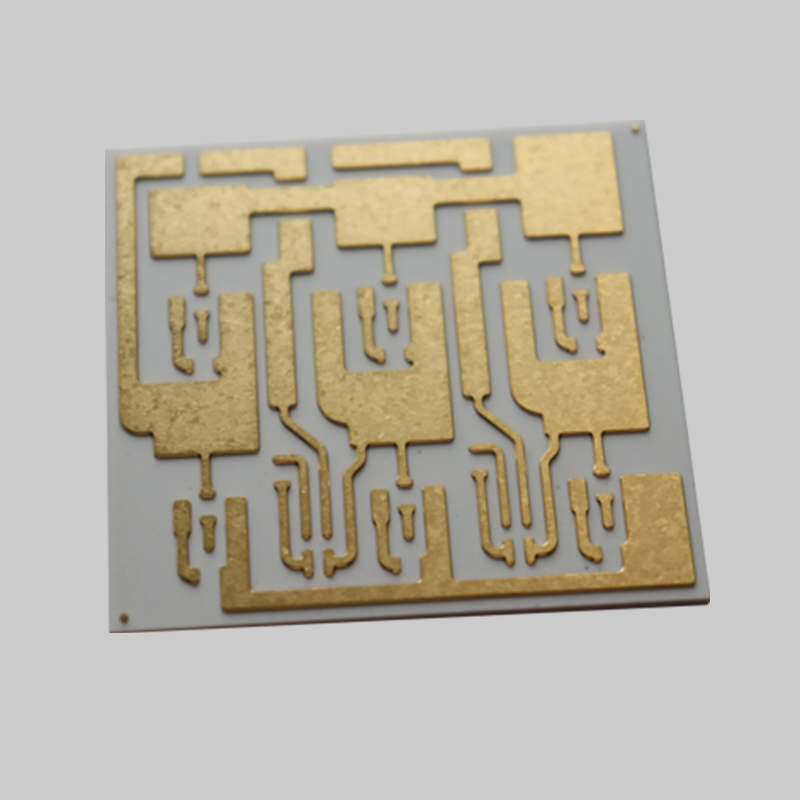

Aluminum nitride Ceramic Applications

Aluminum nitride (AlN) ceramics are widely used across multiple high-tech industries due to their excellent thermal conductivity and electrical insulation properties. They are extensively used in semiconductor and electronic packaging, serving as heat dissipation substrates for high-power devices such as IGBT modules and LEDs, ensuring stable operation. In automotive electronics, AlN is a key heat dissipation material for electric vehicle power modules and battery management systems. Furthermore, AlN plays an important role in microwave and radio frequency equipment, medical devices, and aerospace and defense, providing high-performance heat dissipation and electrical insulation solutions.

Available grades of aluminum nitride material

At Great Ceramic, we offer AlN aluminum nitride ceramics in multiple grades to meet diverse engineering requirements:

Aluminum Nitride Ceramic (AlN-170)

Standard-grade aluminum nitride (AlN) ceramic is an advanced ceramic material that combines high thermal conductivity with excellent electrical insulation properties. It features a low coefficient of thermal expansion and high heat resistance while maintaining good mechanical strength, making it a key material in electronic packaging and thermal management. Standard-grade AlN ceramic strikes a balance between performance and cost and is widely used in thermal management systems for industrial electronics and power devices.

Key Features

Typical Applications

Production and Machining

Standard-grade aluminum nitride ceramics are typically produced from high-purity aluminum nitride powder using a sintering aid-assisted hot pressing (HP) process. To reduce cost and maintain stable performance, standard-grade AlN ceramics incorporate a sintering aid (such as yttrium oxide) into the formulation to enhance sintering density. Diamond tools are typically used for precision cutting, grinding, and polishing to ensure substrate dimensional accuracy and surface quality.

AlN-200 Upgraded Aluminum Nitride

AlN-200 grade aluminum nitride ceramic is an advanced ceramic material with high thermal conductivity and electrical insulation properties. With thermal conductivity reaching 200 W/(m·K) and above, it ranks at the top of the aluminum nitride ceramic performance spectrum. Designed specifically for high-power electronics, optoelectronics, and devices requiring extreme thermal management, it offers thermal conductivity approaching that of copper while maintaining excellent mechanical properties, combined with low thermal expansion characteristics unmatched by alumina ceramics.

Key Features

Typical Applications

Production and Processing

AlN-200 ceramics typically utilize high-purity aluminum nitride powder. Ultra-high density and thermal conductivity are achieved through optimized formulation and high-temperature pressureless sintering or hot isostatic pressing (HIP). During the manufacturing process, the oxygen content is strictly controlled (typically <0.5 wt%) to maximize intergranular heat transfer. The finished substrates often undergo precision grinding, polishing, and metallization (such as Mo/Mn or Ti/Cu plating) to facilitate subsequent soldering and electronic packaging.

AlN-230 Ultra Aluminum Nitride Ceramic

AlN-230 grade aluminum nitride ceramic is an advanced technical ceramic material with ultra-high thermal conductivity (≥230 W/(m·K)), representing the top performance grade within the aluminum nitride family. While maintaining excellent electrical insulation, it achieves thermal conductivity close to or even exceeding that of some metals, making it ideal for applications requiring extreme heat dissipation and high-power electronic packaging.

Compared to standard-grade (150–180 W/(m·K)) and high-grade (200 W/(m·K)) AlN, AlN-230 offers enhanced thermal management performance, significantly reducing device junction temperatures, extending device life, and enabling higher power density designs.

Key Features

Typical Applications

Production and Processing

AlN-230 grade ceramics are made from ultra-high-purity aluminum nitride powder with a strictly controlled oxygen content (typically ≤0.3 wt%). They are manufactured using an optimized sintering additive system and high-temperature pressureless sintering or hot isostatic pressing (HIP) processes. Their dense microstructure and extremely low grain boundary thermal resistance contribute to their ultra-high thermal conductivity.

The finished substrates are precision-ground and polished on both sides to ensure thickness tolerance and surface flatness. Metallization treatments (such as Ti/Cu or Mo/Mn plating) are also available to meet the soldering requirements of electronic packaging.

BN+AlN (Composite) Ceramics

BN+AlN composite ceramics are advanced ceramic materials made by combining hexagonal boron nitride (h-BN) and aluminum nitride (AlN) in a specific ratio. They combine high thermal conductivity, electrical insulation, and excellent machinability.

This material combines the high thermal conductivity, high insulation, and low thermal expansion of AlN with the low density, good lubricity, and easy machinability of BN. It is ideal for electronic and industrial applications requiring efficient thermal management, lightweight structures, and complex fabrication.

Material Characteristics

Typical Applications

Preparation Process

BN+AlN composite ceramics are typically produced by uniformly mixing high-purity aluminum nitride powder and hexagonal boron nitride powder and then producing them through hot pressing or hot isostatic pressing (HIP). Adjusting the BN content can flexibly change the thermal conductivity, strength and processability of the material, achieving a balance between performance and processing costs.

Key Properties of Aluminum Nitride

| Property | AlN-170 (Standard) | AlN-200 (Upgraded) | AlN-230 (Ultra) |

|---|---|---|---|

| Thermal Conductivity (W/m·K) | ≥170 | ≥200 | ≥230 |

| Volume Resistivity (Ω·cm) | >1×1014 | >1×1014 | >1×1014 |

| Dielectric Strength (kV/mm) | >15 | >15 | >15 |

| Coefficient of Thermal Expansion (CTE) (×10⁻⁶/K) | ~4.5 | ~4.5 | ~4.5 |

| Flexural Strength (MPa) | 300 – 400 | 350 – 450 | 350 – 450 |

| Maximum Operating Temperature (°C, in inert atmosphere) | ≥1000 | ≥1000 | ≥1000 |

| Oxygen Content (wt%) | 0.5 – 1.0 | ≤0.5 | ≤0.3 |

| Cost Positioning | Economy | High Performance | Ultra-High Performance |

| Typical Applications | General power electronics packaging, LED heat sink substrates | High-power semiconductor modules, RF/microwave devices | Ultra-high power SiC/GaN modules, high-power lasers, military-grade thermal management |

*The values are typical material properties and may vary according to products configuration and manufacturing process. For more details, Please feel free to contact us.

*Aluminum nitride is easy to be oxidized on the surface, which forms a layer of alumina.This helps to protect the material, but it affects the thermal conductivity (alumina is about 30 W/mK).In an oxidative atmosphere, this occurs at about 700℃.In an inert atmosphere, the layer protects AlN at temperatures as high as about 1350℃.When the temperature is higher than this, bulk oxidation occurs.

Aluminum nitride product application cases

Aluminum nitride ceramics combine high thermal conductivity, excellent electrical insulation, low dielectric constant, and a thermal expansion coefficient close to that of silicon, making them versatile materials suitable for numerous industrial applications. The following are the most common and influential use cases of aluminum nitride products in various fields:

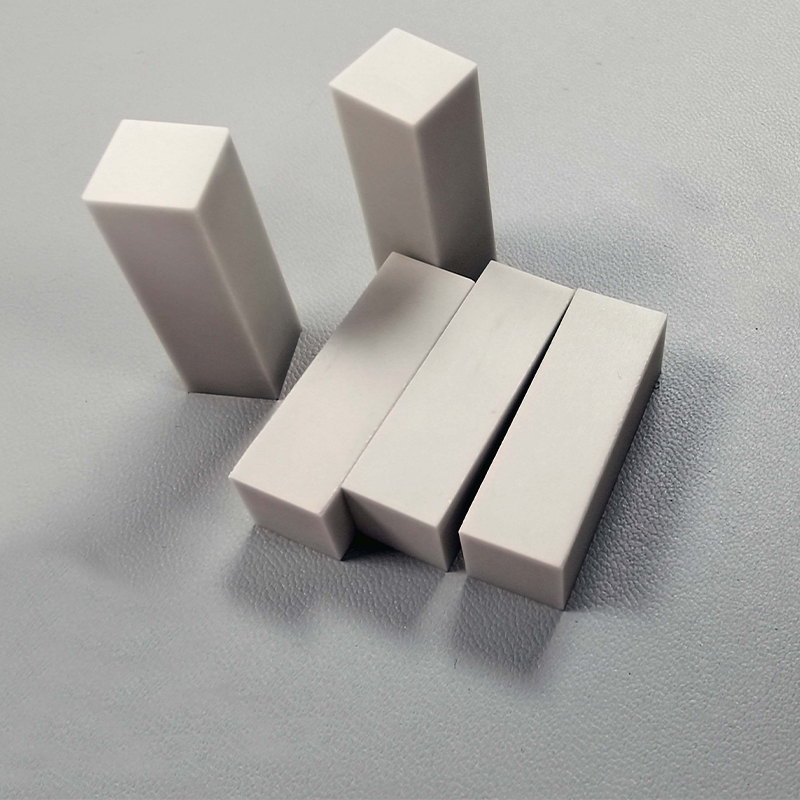

Machining of Aluminum Nitride

Great Ceramic offers AlN aluminum nitride ceramics with high purity and exceptional thermal conductivity aluminum nitride performance, making them ideal for applications that demand both superior heat dissipation and electrical insulation. Aluminum nitride can be formed through several methods, including dry pressing, isostatic pressing, injection molding, and tape casting, depending on the required product geometry and performance.

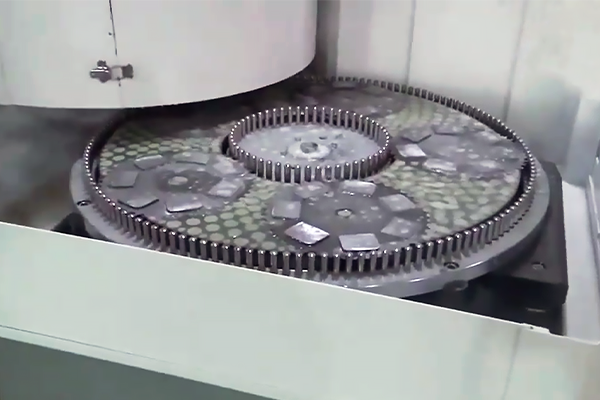

Sintering is a critical step in aluminum nitride ceramic production. High-temperature sintering in a nitrogen atmosphere ensures densification while preserving the material's thermal and electrical properties. Similar to alumina ceramics, AlN aluminum nitride shrinks by about 20% during sintering, which makes achieving precise dimensions in the green state challenging. As a result, post-sintering precision machining is necessary to meet exact tolerances and complex geometries.

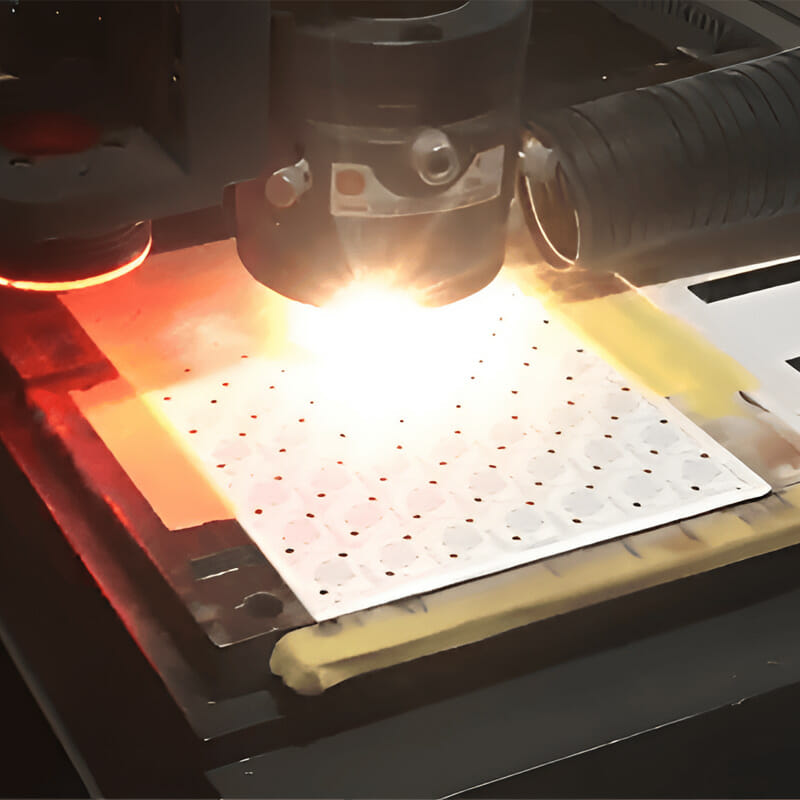

Due to its high hardness and brittleness, aluminum nitride requires specialized techniques such as diamond grinding, laser machining, or ultrasonic processing. Great Ceramic uses advanced CNC ceramic machining systems to produce intricate parts, from aluminum nitride substrates to complex custom components.

With a full suite of advanced processing equipment and extensive technical expertise, Great Ceramic provides end-to-end solutions — from material selection and design optimization to precision machining and assembly — ensuring high-quality, high-performance aluminum nitride ceramic products for the most demanding applications.