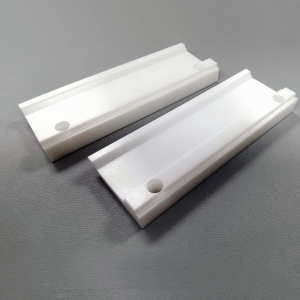

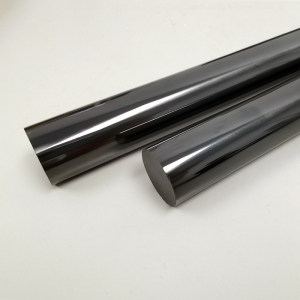

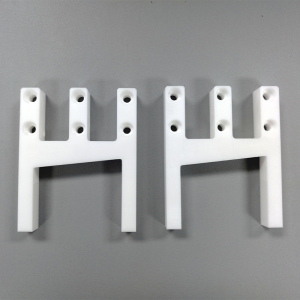

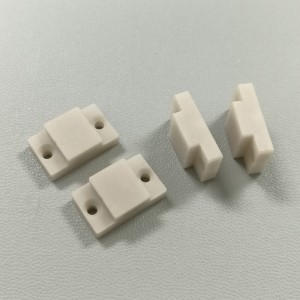

Technical Ceramic Parts

Since the factory founded, we have committed to the development of new products, skilled performance is our work, we adhere to honesty and superior faith working attitude. We welcome new and previous clients from all walks of lifestyle to get in touch with us for long term business relationships and mutual accomplishment! The world is our market – this technical ceramic parts will be supplied globally to West Asia, West Africa, Brazil, New Zealand, etc. While in the past few years, our factory prides itself on a team of cutting-edge technologies, delivering excellence. We strongly think that we will do superior and far better. We warmly welcome you to contact us and please feel free to speak out your needs Great Ceramic collaborates with many factories and qualitified team to provide expert and affordable technical ceramic parts worldwide. We are looking forward to cooperating with you and providing our best services for you, as well as our technical ceramic parts, Aluminum Nitride Ceramics Processing And Sales,Silicon Nitride Ceramics Processing And Sales. As a professional manufacturer, we are capable of meeting your requirements, we accept and consider all orders with unique specifications, each product has met the standards required for professional certification.

Technical Ceramic Parts Boost Profit – Consider Other Products?

Technical Ceramic Parts Cut Down Cost – View Other Pages

More About Technical Ceramic Parts & Great Ceramic

Hello from Great Ceramic, have a look at the most preferred technical ceramic parts here! Great Ceramic has a long history and experience of providingtechnical ceramic parts, which means we are competitive and skillful. With a lengthy track record in this market, we have developed a substantial workforce, operate a spacious factory, and sustain a strong monthly production output. Our technical ceramic parts are outstanding. Quality assurance is at the core of our operations, with strict testing standards, standardized production processes, and comprehensive quality management in place to safeguard the excellence of our technical ceramic parts. Moreover, as a skillful, we have abundant experience of technical ceramic parts and have gain great reputation. Our cooperative network extends to partners from a vast number of countries. The main sales regions we cover span almost every part of the world. We always believe that your request is our command!If you are looking for a well-branded teammate, consider us right now!