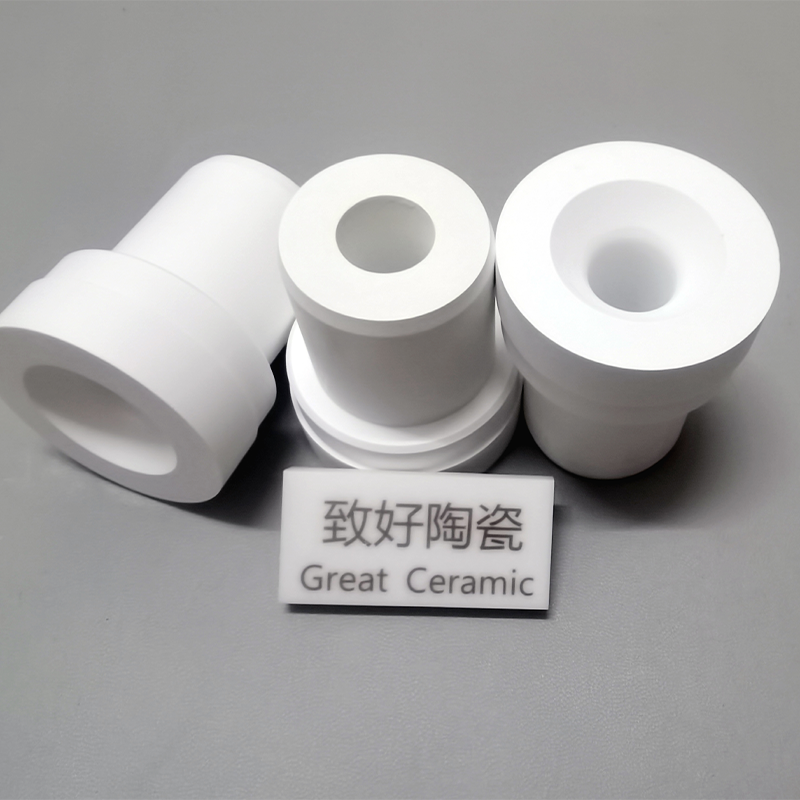

What is boron nitride(BN) ceramics?

Boron nitride(BN) ceramics are made from boron nitride powder by hot pressing and sintering, and then processed according to the size and specifications required by customers.

Density and hardness of BN ceramics

BN ceramics, also known as white graphite, is structurally similar to graphite and belongs to a sheet-like hexagonal structure with a theoretical density of 2.27g/cm3 and a Mohs hardness of 2.

Why use BN ceramics?

Has good electrical insulation, thermal conductivity, excellent chemical stability against thermal shock, and good moisture resistance to molten metal, slag, and glass.

Eight advantages of Boron Nitride ceramics

- High heat resistance: 1500℃ air-cooled to room temperature for dozens of times without breaking, and 2800℃ in inert gas without softening.

- High thermal conductivity: hot-pressed products are 33W/M.K (same as pure iron). When the temperature is above 530 °C, it is the material with the best thermal conductivity among ceramic materials.

- Low thermal expansion coefficient: The expansion coefficient is second only to quartz glass, which is the smallest among ceramics. In addition, it has high thermal conductivity, so it has good thermal shock resistance.

- Excellent electrical properties: good high temperature insulation, the resistivity at room temperature is greater than 10^14Ω·cm, and it can reach 10^3Ω·cm at 2000 °C, which is the best high-temperature insulating material in ceramics.

- Good corrosion resistance: with general metals (iron, copper, aluminum, lead, etc.), rare earth metals, precious metals, semiconductor materials (germanium, silicon, potassium arsenide), glass, molten salt (crystal stone, fluoride) , slag), inorganic acids and alkalis do not react.

- Lower friction coefficient: U is 0.16, it does not increase at high temperature, and it is more resistant to high temperature than molybdenum disulfide and graphite.

- High purity: its impurity content is less than 10PPM, while the boron content is greater than 43.6%.

- Machinability: low hardness, can be processed into parts with high precision by general machining methods.

Precautions for maching Boron Nitride ceramics

The boron nitride ceramic material has excellent machinability and can be machined into complex shapes with extremely tight tolerances as required. The following should be noted:

1. All boron nitride ceramic materials can be processed with standard high-speed steel cutting tools. For the processing of hard composite materials, carbide tools or diamond tools are recommended.

2. Grinding can be performed as required, and standard taps and die can be used to process threads.

3. The machining process should always be kept dry without the use of cutting oil and coolant.

4. Cutting tools should be sharp and clean, and cutting tools with negative inclination should not be used.

5. When processing materials, be careful when jamming and clamping to avoid applying excessive pressure. Climb milling technology should be used to prevent missing edges and corners.