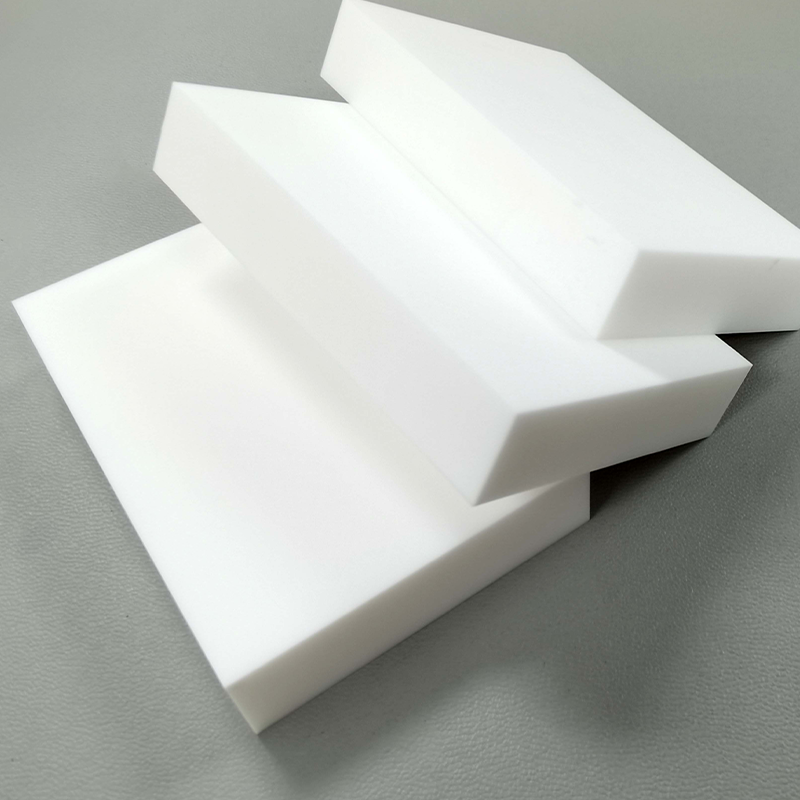

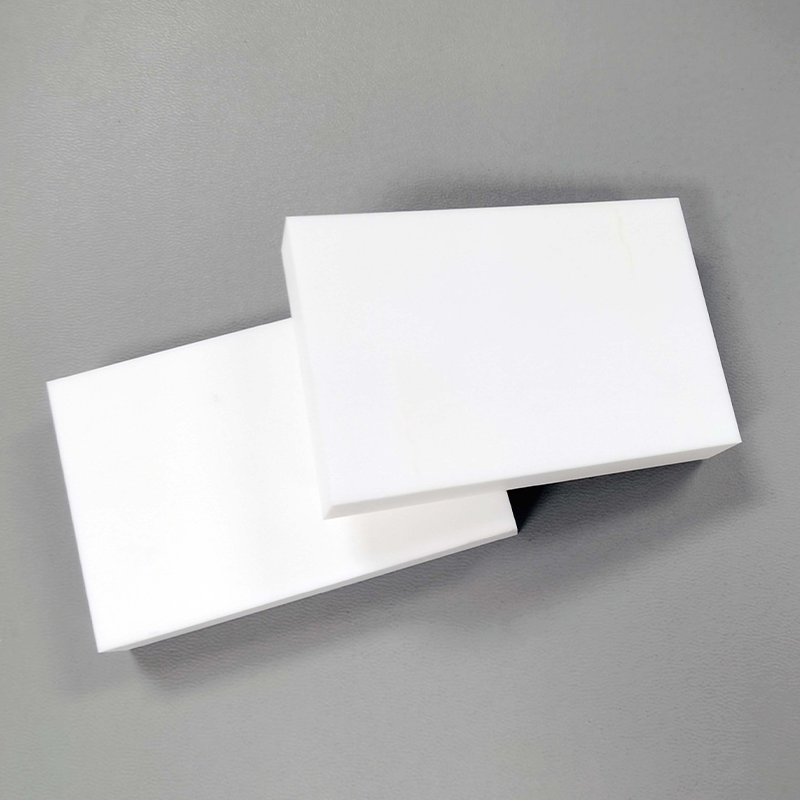

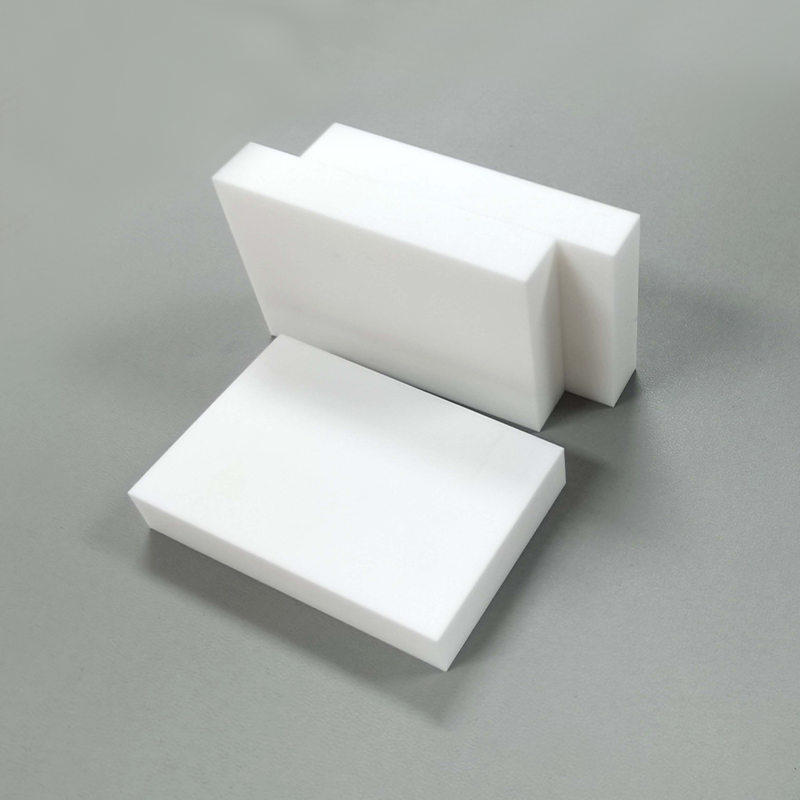

Advantages of machinable ceramic blocks

One of the main advantages of machinable ceramics is that it can be machined with conventional metalworking tools. This allows for significantly faster turnarounds and substantially lower production costs when compared with other technical ceramics, making it an excellent material for both prototyping and medium-volume production runs.

Machinable Ceramic Block Feature

- Density: 2.5(g/cm³)

- Mohs Hardness: 4~5

- Maximum Temperature: 800(℃)

- Thermal Conductivity @ 25°C: 1.46(W/mK)

- Dielectric Strength: >40(KV/mm)

- Volume Resistivity @ 20°C : >1014(Ω.cm)

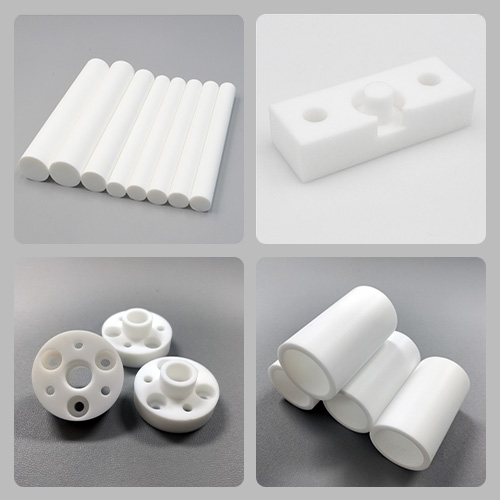

Structure

Great Ceramic has rich experience in milling, grinding and polishing precision (Advanced) ceramics and firing ceramics, which enables us to achieve:

- Shape and size can be customized according to requirements;

- The shape accuracy of square shaped products can reach ± 0.05 mm generally, and ± 0.01 mm at the most precise;

- The dimensional accuracy of tubular products can reach ± 0.05mm in general and ± 0.01mm in the most precise case;

- The dimensional accuracy of the internal groove and round hole is generally about ± 0.05 mm, and the position accuracy is within 0.1 mm;

- Please contact us for other details of the structure.

All tolerances can be improved upon depending on the size, shape & geometry of the precision ceramic part. Great Ceramic is dedicated to ensuring we make only the highest quality parts that meet or exceed our customers specifications.

Why Choose Us?

Great Ceramic has accumulated many years of experience in the pursuit of developing the best precision (Advanced) ceramic parts in the world, and is constantly applying this knowledge every day. In fact, we have been involved in the production of precision ceramics by many customers.

Contact us to find out what we can do for you.

- We can reply to your inquiry within 24 hours (except on Saturdays and Sundays);

- We can provide customized product service for you;

- We can accept the customized service of 1 product.

Packing and Shipping