- Home

- Technical Ceramics Category And Application

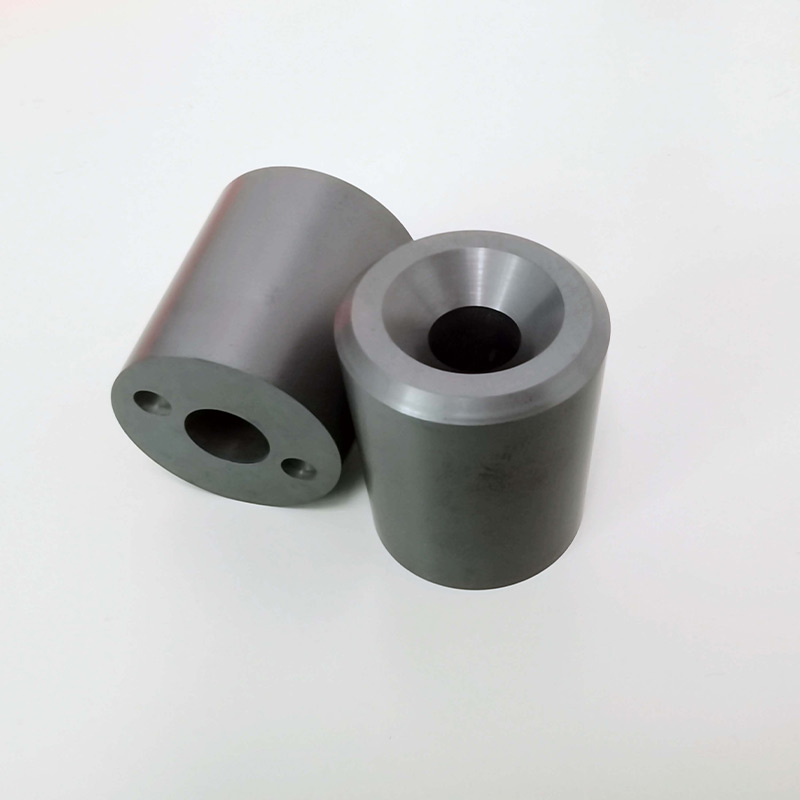

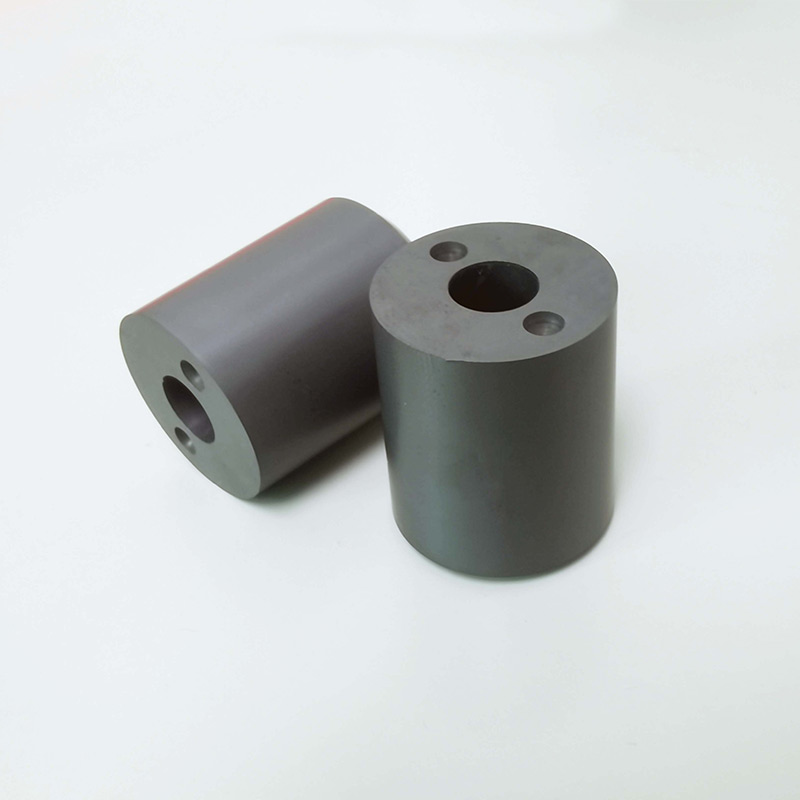

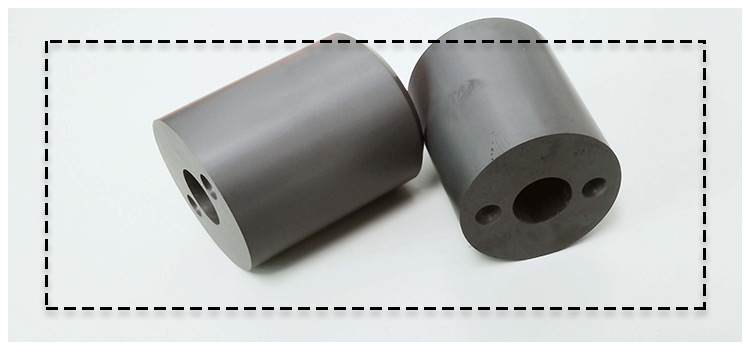

- Customized Silicon Carbide Ceramic Sheath

Customized Silicon Carbide Ceramic Sheath

- Can be customized according to requirements;

- Can make very complex structures;

- The surface can be polished;

- It can be used at 1400 ℃;

- High hardness, very wear-resistant;

- High corrosion resistance;

Advantages Of Silicon Carbide Ceramic Sheath

Silicon carbide ceramic sheath uses SIC materials with excellent mechanical properties, excellent oxidation resistance, high wear resistance and low friction coefficient, so that it can be used in extremely harsh environments, or to extend the service life of parts.

Silicon Carbide Ceramic Sheath Applications

Generally, SIC ceramic sheath is used because of its ultra-high hardness, oxidation resistance and high temperature resistance. In some applications that are very easy to wear and have high service temperature, the use of SIC sheath as a component can effectively extend the service life, so it has great economic benefits.

In addition, due to the superior performance of the parts made of silicon carbide, they have been widely used in petroleum, chemical industry, microelectronics, automobile, aerospace, aviation, paper making, laser, mining, atomic energy and other industrial fields.

Now, silicon carbide has been widely used in the fields of high-temperature bearings, bulletproof plates, nozzles, high-temperature corrosion resistant parts and electronic equipment components in the high-temperature and high-frequency range.

Silicon Carbide Ceramic Sheath Performance

SiC ceramic sheath prepared by direct sintering has the characteristics of high hardness, corrosion resistance, oxidation resistance and low friction coefficient. In addition, the greatest feature of silicon carbide ceramics is that they can still maintain high mechanical strength at high temperatures. The strength of ordinary ceramic materials will be significantly reduced at 1200~1400 ℃, while the bending strength of silicon carbide will remain at a higher level at 1400 ℃.

The basic characteristics of directly sintered silicon carbide ceramics are as follows:

- Colour: Dark Gray

- Density: 3.15g/cm³

- Porosity: ≤0.1%

- Hardness: 22GPa

- Compressive Strength: 2600MPa

- Flexural Strength: 400MPa

- Elastic Modulus: 410GPa

- Maximum Use Temperature: 1400℃

- Thermal Conductivity: 100~120W/(m・K)

- Coefficient Of Thermal Expansion: 4 x 10-6/°C

Silicon Carbide Ceramic Sheath Manufacturer

Great Ceramic has been engaged in precision technical ceramics for many years, and has rich experience in milling, grinding and polishing silicon carbide(SIC) ceramics. We can:

- Customized ceramic products according to requirements;

- Manufacturing very complex ceramic products;

- Achieve high dimensional accuracy;

- Fast response and delivery;

- Provide more professional services.

Great Ceramic can improve all tolerances according to the size and structure of precision advanced ceramic products. Great Ceramic is committed to ensuring that we only produce the highest quality precision ceramic parts that meet or exceed customer specifications.

Contact us to find out what we can do for you!

- We will reply to your message within 24 hours;

- We can provide you with technical consulting services;

- We support any number of product customization;

- We are happy to provide service for you.

Packing and Shipping

Great Ceramic's Silicon Carbide Ceramic Sheath has been carefully processed to minimize damage during storage and transportation and maintain the quality of our products in the original state.