- Home

- Technical Ceramics Category And Application

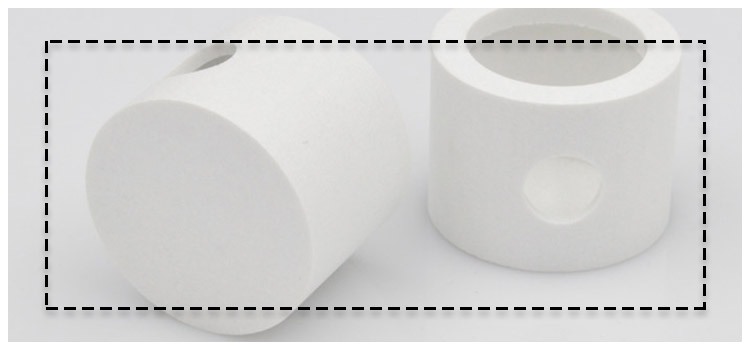

- Boron nitride ceramic structural parts

Boron nitride ceramic structural parts

- Shape and size can be customized according to requirements

- Mohs hardness as low as 2, is a kind of soft material easy to process

- The thermal conductivity is as high as 33W / M.K. it is the highest in ceramic materials above 530 ℃

- It has excellent electrical properties, low expansion coefficient and good corrosion resistance

Boron Nitride

BN

Boron nitride is a crystal composed of nitrogen atoms and boron atoms. The crystal structure is divided into hexagonal boron nitride (HBN), closely packed hexagonal boron nitride (WBN) and cubic boron nitride. The crystal structure of hexagonal boron nitride has graphite layered structure, showing loose, lubricating, easy to absorb moisture, light weight and other properties of white powder, so it is also called "white graphite".

The expansion coefficient of hexagonal boron nitride is equivalent to that of quartz, but its thermal conductivity is ten times that of quartz. It also has good lubricity at high temperature. It is an excellent high temperature solid lubricant. It has strong neutron absorption capacity, stable chemical properties, and is chemically inert to almost all molten metals.

Feature

Lower density: 2.27g/cm,Lower than most ceramics

High thermal conductivity: the thermal conductivity of hot pressed products is 33W / M.K, which is the largest among ceramic materials above 530 ℃.

Low thermal expansion coefficient: 2×10-6 is the smallest expansion coefficient in ceramics, next only to quartz glass

The lower friction coefficient: U is 0.16 and does not increase at high temperature

Good corrosion resistance: no chemical reaction with general molten metal

Toxicological safety

Structure

Great Ceramic has rich experience in milling, grinding and polishing precision (Advanced) ceramics and firing ceramics, which enables us to achieve:

- Shape and size can be customized according to requirements;

- The shape accuracy of square shaped products can reach ± 0.1 mm generally, and ± 0.01 mm at the most precise;

- The dimensional accuracy of tubular products can reach ± 0.05mm in general and ± 0.01mm in the most precise case;

- The dimensional accuracy of the internal groove and round hole is generally about ± 0.1 mm, and the position accuracy is within 0.1 mm;

- Please contact us for other details of the structure.

All tolerances can be improved upon depending on the size, shape & geometry of the precision ceramic part. Great Ceramic is dedicated to ensuring we make only the highest quality parts that meet or exceed our customers specifications.

Why Choose Us

Great Ceramic has accumulated many years of experience in the pursuit of developing the best precision (Advanced) ceramic parts in the world, and is constantly applying this knowledge every day. In fact, we have been involved in the production of precision ceramics by many customers.

Contact us to find out what we can do for you.

- We can reply to your inquiry within 24 hours (except on Saturdays and Sundays);

- We can provide customized product service for you;

- We can accept the customized service of 1 product.

Packing and Shipping