- Home

- Technical Ceramics Category And Application

- Beryllium Oxide Ceramic Blocks

Beryllium Oxide Ceramic Blocks

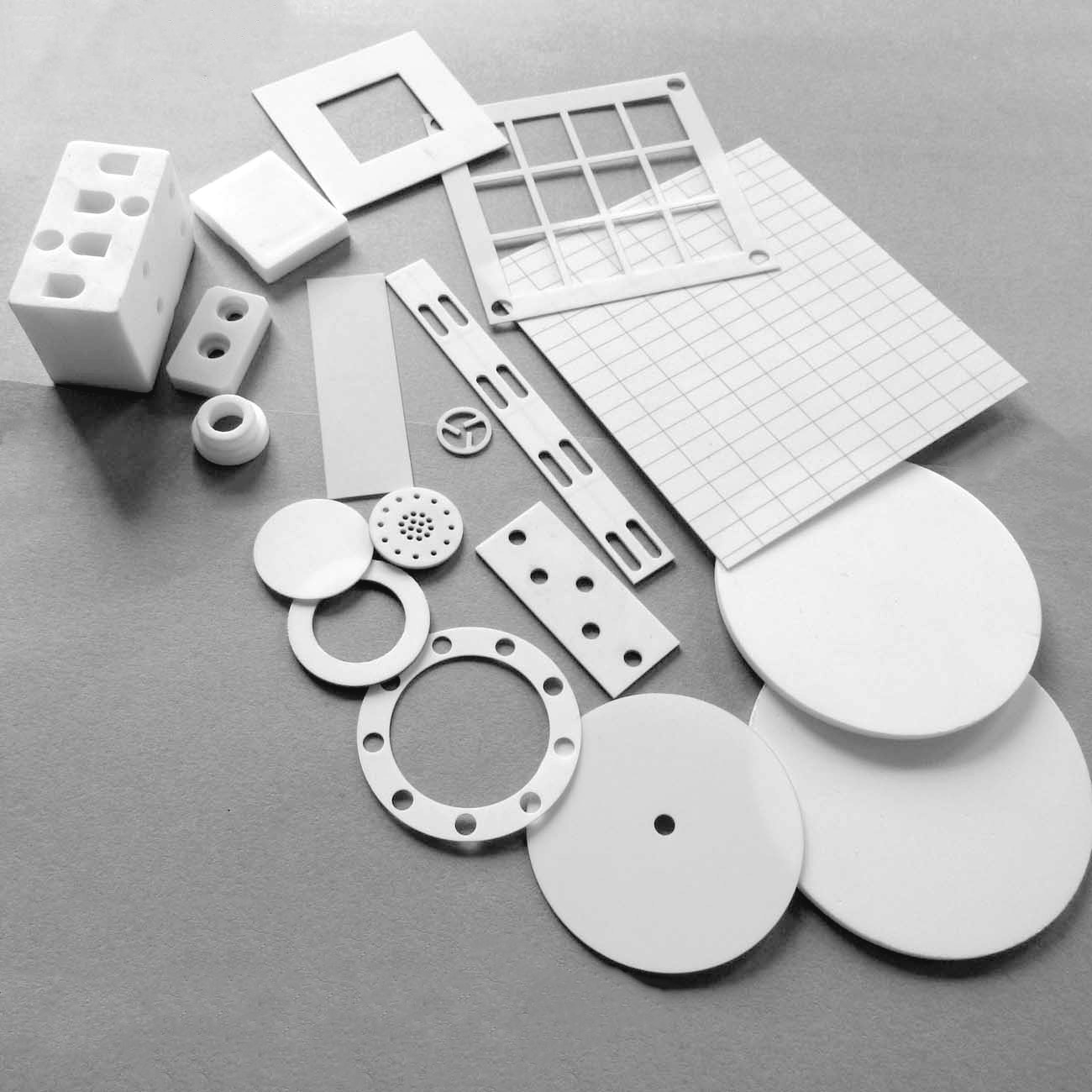

- Customizable Machining

- High thermal conductivity

- High electrical insulation

- High temperature resistance

- High hardness

What is Beryllium Oxide Ceramic Blocks?

Beryllium oxide (BeO) ceramic blocks stand as the undisputed champions of thermal management in the world of advanced materials. Boasting the second highest thermal conductivity of all electrically insulating materials, surpassed only by diamonds, these innovative blocks offer a game-changing solution for applications plagued by heat buildup.

Properties of beryllium oxide blocks

- High Thermal Conductivity: Beryllium oxide ceramic blocks exhibit a very high thermal conductivity, which is approximately 240 W/mK. This property makes them an ideal choice for applications that require efficient heat dissipation, such as electronic components and thermal management systems.

- Low Thermal Expansion: These ceramic blocks have a low coefficient of thermal expansion (CTE), which is around 7.5 x 10-6 K-1. This property ensures that they have excellent thermal shock resistance and can withstand sudden temperature changes without cracking or degrading their mechanical strength.

- High Mechanical Strength: Beryllium oxide ceramic blocks possess a high mechanical strength, with a Vickers hardness of around 700 kg/mm2. This property makes them suitable for applications that require a strong and durable ceramic material.

- High Dielectric Strength: These ceramic blocks have a high dielectric strength of approximately 25 kV/mm, which makes them an excellent choice for electronic components and insulators.

- Low Loss Factor: Beryllium oxide ceramic blocks have a low loss factor, which is typically around 0.005 at 1 MHz. This property is crucial for applications that require minimal signal loss, such as RF and microwave components.

- Chemical Inertness: These ceramic blocks are highly resistant to chemical attack and can withstand exposure to a wide range of chemicals, including acids, bases, and organic solvents. This property makes them suitable for use in harsh environments and chemical processing applications.

- Low Density: Beryllium oxide ceramic blocks have a low density of around 2.9 g/cm3, which is approximately 60% of the density of alumina. This property makes them lightweight and easy to handle, while still maintaining their high strength and durability.

Applications of Beryllium Oxide Ceramic Blocks

Due to their unique combination of properties, beryllium oxide ceramic blocks are used in a wide range of applications across various industries. Some of these applications include:

- Electronic Components: Beryllium oxide ceramic blocks are commonly used in the manufacturing of electronic components, such as capacitors, inductors, transformers, and magnetic heads, due to their high dielectric strength and low loss factor.

- Thermal Management: These ceramic blocks are used in thermal management systems, such as heat sinks and heat spreaders, due to their high thermal conductivity and ability to dissipate heat efficiently.

- Structural Components: Beryllium oxide ceramic blocks can be used as structural components in various applications, such as aerospace and automotive engineering, due to their high mechanical strength and lightweight nature.

- Chemical Processing: These ceramic blocks are used in chemical processing applications, such as reactors and storage vessels, due to their chemical inertness and ability to withstand harsh environments.

- Medical Implants: Beryllium oxide ceramic blocks can be used in medical implants, such as hip replacements and dental implants, due to their biocompatibility and ability to withstand the harsh environment of the human body.

Considerations and Responsible Handling

While BeO's performance reigns supreme, it's crucial to acknowledge its potential health hazards. Beryllium dust is a known carcinogen, necessitating proper safety protocols and controlled environments during machining and handling.

Investing in Cutting-Edge Technology:

Beryllium oxide ceramic blocks represent the cutting edge of thermal management solutions. Their phenomenal performance opens doors to previously unimaginable possibilities in diverse industries. When paired with responsible handling practices, BeO blocks offer a powerful tool for unlocking the full potential of heat-sensitive applications.

Contact us to find out what we can do for you!

- We will reply to your message within 24 hours;

- We can provide you with technical consulting services;

- We support any number of product customization;

- We are happy to provide service for you.

Packing and Shipping

Great Ceramic's beryllium oxide ceramic has been carefully processed to minimize damage during storage and transportation and maintain the quality of our products in the original state.