Metallized Ceramics Solution

At Great Ceramic, we specialize in metallized ceramics solutions tailored for high-performance industrial and electronic applications. With a strong foundation in advanced ceramic machining, we deliver custom ceramic metallization services that enable robust, high-temperature, and hermetically sealed ceramic-to-metal assemblies.

Whether your application requires ceramic-to-metal feedthroughs, vacuum electronic packaging, or high-reliability metallized substrates, our engineering and processing capabilities ensure consistent quality and high-performance results.

Skip to

Introduction | Capabilities | Cases | Materials | Applications | FAQs

What are Metallized ceramics?

Metallized ceramics represent a cornerstone in modern ceramic packaging technology, enabling reliable, high-strength, and hermetically sealed joints between ceramic and metal components. By depositing a functional metal layer onto an insulating ceramic surface, we create surfaces that support brazing ceramics to metal, vacuum electronic packaging, and electrical connectivity while retaining the intrinsic benefits of advanced ceramics.

Why Metallized Ceramics?

Ceramics such as alumina (Al₂O₃), aluminum nitride (AlN), zirconia (ZrO₂), and silicon nitride (Si₃N₄) possess excellent thermal stability, wear resistance, and electrical insulation. However, they are difficult to bond directly to metals due to poor wettability and mismatched thermal expansion.

Metallization technology overcomes these limitations by forming a metallurgical bond between ceramic and metal via various methods—enabling:

What We Do: Ceramic Metallization Capabilities

Great Ceramic delivers high-reliability metallized ceramics using proprietary Mo/Mn and Mo/Mn/W coatings, enabling precise, hermetic ceramic-to-metal brazing. With in-house plating, tight-tolerance machining, and full testing for strength and seal integrity, we provide custom solutions for medical, electronic, power, and sensor applications. The metallization performance indicators are as follows:

Metallization Techniques Offered

Our experts work with you to select the best metallization materials and processes to achieve reliable, high-strength brazed joints, even in challenging geometries.

Metallization Application Methods

We will choose the appropriate method based on the product structure (cylindrical, flat, inner hole) as well as batch and precision requirements.

Metallized ceramic case

We will custom produce metallized alumina ceramics for ultra-high vacuum feedthroughs, vacuum isolator flanges, gas discharge tubes, grid tubes, vacuum circuit breakers, vacuum capacitors and similar applications according to customer drawings and requirements.

Metallized Ceramic Insulator

Vacuum Ceramic Component

Metallized Ceramic Insulator

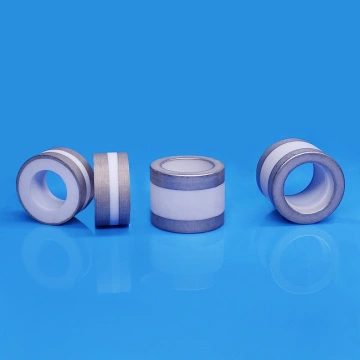

Metallized Ceramic Ring

Optional metallized ceramic materials

We offer a wide range of high purity metallized alumina ceramic components (95%~99.7% purity) for thick film metallization of molybdenum (Mo-Mn) and tungsten (W). The main metallization methods used include screen printing or vacuum sputtering, followed by electroplating or chemical plating on the metallized surface with nickel, gold, silver or tin. In this way, ceramics can be welded with oxygen-free copper, Kovar, stainless steel and other alloys. The material parameters are as follows:

| Project title | Unit | 96% Al2O3 | 97% Al2O3 | 99% Al2O3 | 99.6% Al2O3 |

| Alumina content | % | Al2O3≧95% | Al2O3≧97% | Al2O3≧99% | Al2O3≧99.6% |

| Size range | mm | 0.5-500 | 0.5-500 | 0.5-500 | 0.5-500 |

| Highest accuracy | mm | 0.01 | 0.01 | 0.01 | 0.01 |

| Bulk density | g/cm3 | ≧3.67 | ≧3.70 | ≧3.85 | ≧3.90 |

| Flexural strength | MPa (25℃) | ≧300 | ≧300 | ≧350 | ≧400 |

| Compressive strength | GPa (25℃) | ≧1.8 | ≧1.8 | ≧2.0 | ≧2.3 |

| Thermal conductivity | W/m.K | 10-20 | 10-20 | 15-21 | 15-21 |

| Average linear expansion coefficient | /℃ (20~500℃) | 7.36×10-6 | 6.9×10-6 | 6.9×10-6 | 6.9×10-6 |

| Dielectric constant | 1MHz (20℃) | 9.1 | 9.5 | 9.8 | 10 |

| Dielectric loss tangent value | 1MHz (20℃) | ≦4×10-4 | ≦3×10-4 | ≦2×10-4 | ≦2×10-4 |

| Volume resistivity | Ω.cm (100℃) | ≧1×1014 | ≧1×1014 | ≧1×1014 | ≧1×1014 |

| DC breakdown strength | KV/mm | ≧30 | ≧35 | ≧25 | ≧25 |

| Thermal shock resistance | ℃ | 20~800 | 20~800 | 20~800 | 20~800 |

| Maximum operating temperature | ℃ | ≦1300 | ≦1400 | ≦1500 | ≦1500 |

| Acid resistance | General | Suitable | First-rate | First-rate | |

| Alkali resistance | General | Suitable | Suitable | First-rate | |

| Ease of metallization | Easy | Normal difficulty | Medium difficulty | Very difficult | |

| Air tightness | Pa•m3/s | ≦1×10-11 | ≦1×10-11 | ≦1×10-10 | ≦1×10-9 |

| Average Tension strength | MPa | 130 | 130 | 130 | 130 |

Note: Each batch may be different, for reference only.

Note: Please view it on your computer.

Applications of Metallized Ceramics

Frequently Asked Questions (FAQ)

Customize your metallized ceramic parts

With more than a decade of experience in advanced ceramic manufacturing, Great Ceramic understands that the success of metallized ceramics lies in interface engineering, material compatibility, and tight tolerances. Every step of our process is customized to your design, environment, and joining method.

Whether you are building a one-off prototype or preparing for large-scale production, we support flexible order quantities and serve customers in Europe, North America, and Asia.