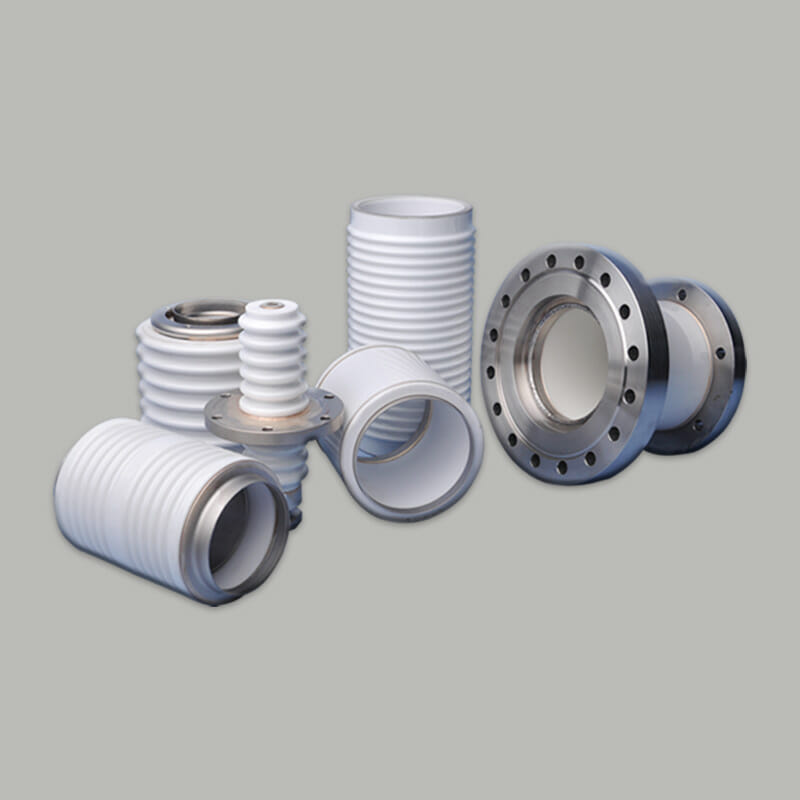

Ceramic and Metal Brazed Assemblies

The brazing assemblies uses valveable materials or oxygen-free copper parts with a similar expansion coefficient to the ceramic parts and metallized ceramic parts to achieve sealing between the ceramic and the metal through brazing. The sealing parts can be argon arc welded with stainless steel, thereby Achieve air-tight connection between ceramic parts and metal structural parts.

Brazed Assemblies Company

Great Ceramic provides precision brazing of dissimilar materials such as metals and ceramics to create high-performance brazed assemblies. Skilled technicians and state-of-the-art facilities allow us to provide custom brazed parts for the most demanding applications.

Uses of brazed assemblies

Ceramic and metal brazing assemblies are mainly used in electron tubes, launch tubes, microwave tubes, traveling wave tubes, vacuum gauge tubes, accelerating tubes, trigger tubes, thyristors, X-ray tubes, CT tubes, high-voltage electrodes and other fields. Especially in the field of high-power, high-reliability packaged electronic products, it shows excellent performance.

Our Brazing Capabilities

– Vacuum and controlled atmosphere brazing up to 2200°F

– Resistance heating and induction brazing for rapid, localized heat

– Broad selection of active metal and silver-based filler metals

– Precise joint clearance control (±0.001")

– Ultra-clean material preparation and handling

– Advanced inspection using scanning acoustic microscopy

Brazed Assemblies Technical Parameters

| Project title | Unit | 96% Al2O3 | 97% Al2O3 | 99% Al2O3 | 99.6% Al2O3 |

| Alumina content | % | Al2O3≧95% | Al2O3≧97% | Al2O3≧99% | Al2O3≧99.6% |

| Size range | mm | 0.5-500 | 0.5-500 | 0.5-500 | 0.5-500 |

| Highest accuracy | mm | 0.01 | 0.01 | 0.01 | 0.01 |

| Bulk density | g/cm3 | ≧3.67 | ≧3.70 | ≧3.85 | ≧3.90 |

| Flexural strength | MPa (25℃) | ≧300 | ≧300 | ≧350 | ≧400 |

| Compressive strength | GPa (25℃) | ≧1.8 | ≧1.8 | ≧2.0 | ≧2.3 |

| Thermal conductivity | W/m.K | 10-20 | 10-20 | 15-21 | 15-21 |

| Average linear expansion coefficient | /℃ (20~500℃) | 7.36×10-6 | 6.9×10-6 | 6.9×10-6 | 6.9×10-6 |

| Dielectric constant | 1MHz (20℃) | 9.1 | 9.5 | 9.8 | 10 |

| Dielectric loss tangent value | 1MHz (20℃) | ≦4×10-4 | ≦3×10-4 | ≦2×10-4 | ≦2×10-4 |

| Volume resistivity | Ω.cm (100℃) | ≧1×1014 | ≧1×1014 | ≧1×1014 | ≧1×1014 |

| DC breakdown strength | KV/mm | ≧30 | ≧35 | ≧25 | ≧25 |

| Thermal shock resistance | ℃ | 20~800 | 20~800 | 20~800 | 20~800 |

| Maximum operating temperature | ℃ | ≦1300 | ≦1400 | ≦1500 | ≦1500 |

| Acid resistance | General | Suitable | First-rate | First-rate | |

| Alkali resistance | General | Suitable | Suitable | First-rate | |

| Ease of metallization | Easy | Normal difficulty | Medium difficulty | Very difficult | |

| Air tightness | Pa•m3/s | ≦1×10-11 | ≦1×10-11 | ≦1×10-10 | ≦1×10-9 |

| Tension strength | Kg/cm2 | 3 | 3 | 3 | 3 |

Note: Each batch may be different, for reference only.

Note: Please view it on your computer.

Brazing Metals to Ceramics

Brazing provides a reliable process to join metals and ceramics in lightweight, high strength assemblies. We carefully select compatible materials and brazing filler metals to create tailored joints. Common material combinations include:

| ceramics | 95%Al2O3 | 97%Al2O3 | Sapphire | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Metal | AgCu28 | OFC | Ag | AuSn20 | AgCu28 | OFC | Ag | AuSn20 | AgCu28 | OFC | Ag | AuSn20 |

| Kovar 4J33 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| Kovar 4J34 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| OF-Cu | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||

| Au | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||

| Au | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

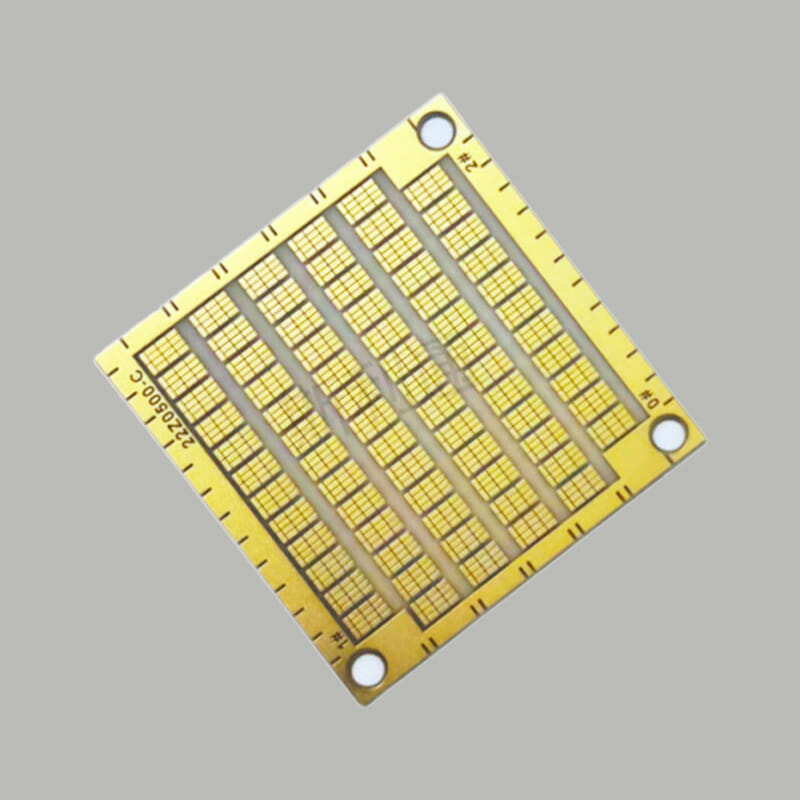

Learn about ceramic substrate metallization

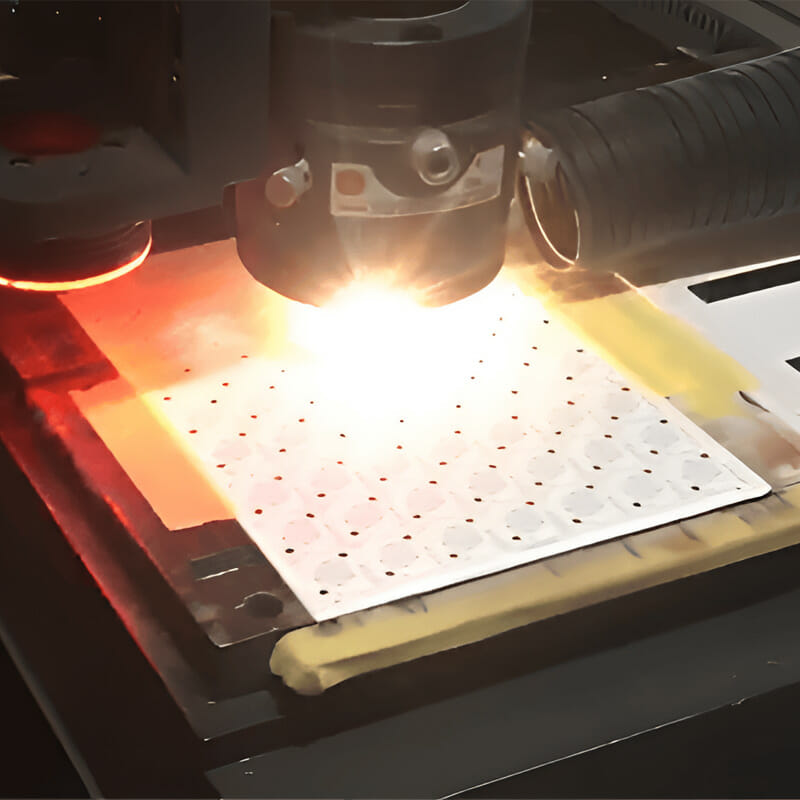

Learn about laser processing of ceramic substrates