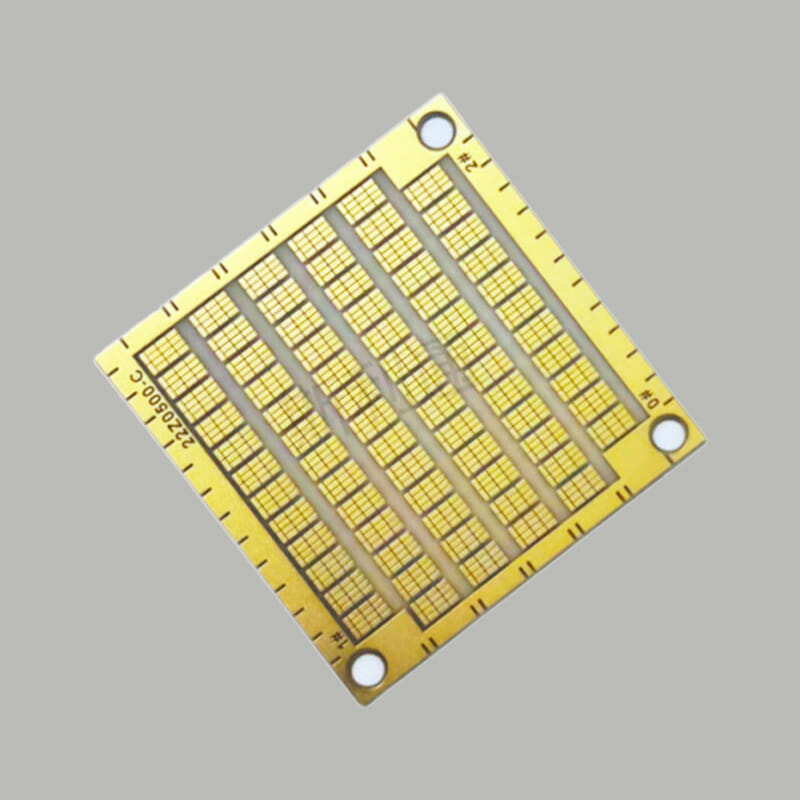

Aluminum Nitride (AlN) Substrate

Aluminum nitride ceramic substrates have high thermal conductivity, low dielectric coefficient and dielectric loss, and excellent mechanical properties, making them one of the most ideal choices for electronic applications. It is widely used in information communications, LED packaging, semiconductors, power modules (IGBT), image sensing, new energy, electronic appliances and other fields.

ALN Substrate Manufacturing Company

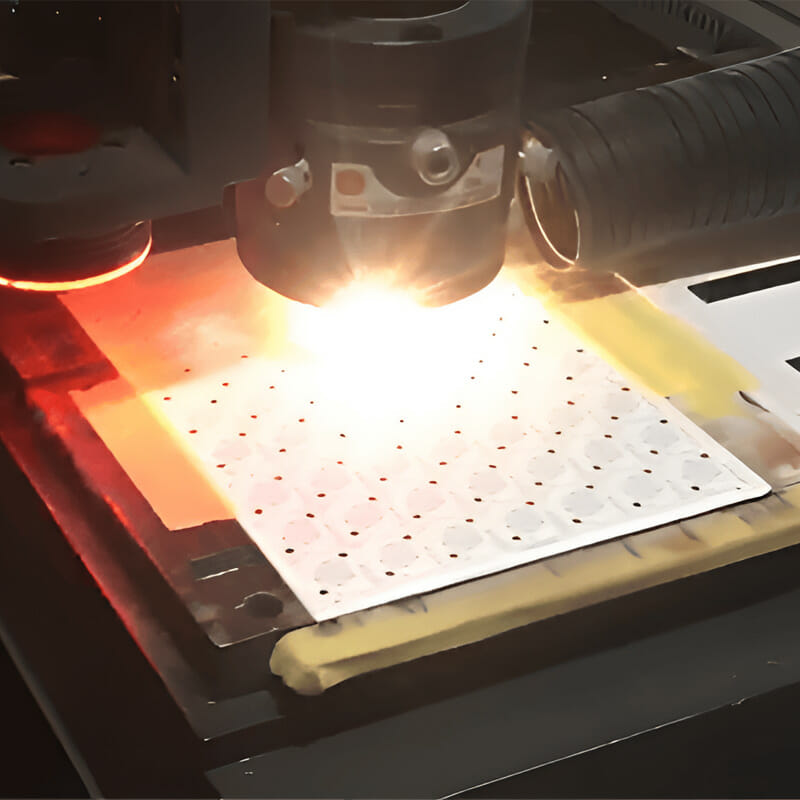

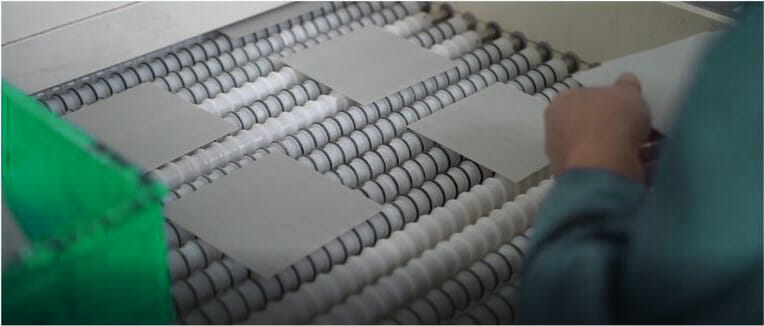

Great Ceramic offers aluminum nitride ceramic substrates produced by tape casting. The shape and size can be customized according to customer needs, the surface can also be polished, or various shapes can be customized through laser cutting and other processes, and are suitable for various metallization processes.

Properties of AlN Ceramic Substrate

Basic properties of ceramic substrates

| Items | Unit | AlN-170 | AlN-200 | AlN-230 |

| Color | – | Gray/Beige | Gray/Beige | Gray/Beige |

| Volume density | g/cm³ | 3.3 | 3.3 | 3.3 |

| Surface roughness | um(Ra) | <0.8 | <0.8 | <0.8 |

| Camber | length ‰ | ≤3 | ≤3 | ≤3 |

Mechanical properties of substrate

| Items | Unit | AlN-170 | AlN-200 | AlN-230 |

| Bending Strength | MPa | ≥400 | ≥350 | ≥300 |

| Fracture Toughness | MPa·m1/2 | 3.0 | 2.6 | 2.4 |

| Vickers Hardness | GPa | 11 | 11 | 11 |

Thermal properties of the substrate

| Items | Unit | AlN-170 | AlN-200 | AlN-230 |

| Thermal conductivity | W/m·k(25℃) | ≥170 | ≥195 | ≥225 |

| Thermal expansion coefficient | ×10-6/k (20℃~800℃) | 4~6 | 4~6 | 4~6 |

| Thermal shock resistance | ≥10(800℃) | No cracks | No cracks | No cracks |

| Heat capacity | J/(kg·k) | 720 | 720 | 720 |

Electrical properties of the substrate

| Items | Unit | AlN-170 | AlN-200 | AlN-230 |

| Volume resistance | Ω·cm(20℃) | ≥1014 | ≥1013 | ≥1013 |

| Dielectric constant | 1MHz | 9.0 | 8.7 | 8.5 |

| Dielectric loss | 1MHz | 4×10-4 | 4×10-4 | 4×10-4 |

| Dielectric strength | KV/mm | ≥15 | ≥15 | ≥15 |

Note: Each batch may be different, for reference only.

Note: Please view it on your computer.

Dimensions Of Ceramic Substrate

Great Ceramic offers a variety of standardized sizes of aluminum nitride (AlN) ceramic to meet customer needs. In addition, we also provide customers with customized services for ceramic substrates, and the size of the substrate can be customized according to customer needs.

| Size(mm) | ||||||

| Thickness | 50.8×50.8 | 114.3×114.3 | 120×120 | 140×190 | 254×254 | 300×300 |

| 0.25 | √ | √ | √ | – | – | – |

| 0.38 | √ | √ | √ | – | – | – |

| 0.5 | √ | √ | √ | √ | – | – |

| 0.635 | √ | √ | √ | √ | √ | √ |

| 1 | √ | √ | √ | √ | √ | √ |

| 1.5 | √ | √ | √ | √ | √ | √ |

| 2 | √ | √ | √ | √ | √ | √ |

Advantages of aluminum nitride ceramic substrates

- Conduct strict quality control from raw materials to finished products to ensure uniform quality;

- Provide customized processing services, including size adjustment, surface polishing, laser cutting, etc. according to needs;

- Widely used in ceramic metallization, such as DPC (direct copper plating method), thin film sputtering method, DBC (direct copper plating method), AMB (active copper brazing method), thick film printing, etc.;

- The minimum thickness can reach 0.1 mm.

Conclusion

Aluminum nitride (AlN) ceramic substrates are vital components in modern electronics, offering a unique combination of high thermal conductivity and electrical insulation. Whether you’re looking for an aluminum nitride sheet, substrate, or ceramic material, AlN’s properties make it a top choice for advanced electronic applications.

For more information about our aluminum nitride (AlN) products, including specifications and customization options, please contact us.

Learn about ceramic substrate metallization