Alumina Ceramic

Alumina ceramic—also known as alumina oxide ceramic, ceramic alumina, or Al₂O₃ ceramic—is one of the most important and versatile advanced technical ceramics in modern engineering. With its exceptional combination of mechanical strength, hardness, corrosion resistance, thermal stability, and electrical insulation, alumina is a preferred material for demanding applications where metals and polymers fail.

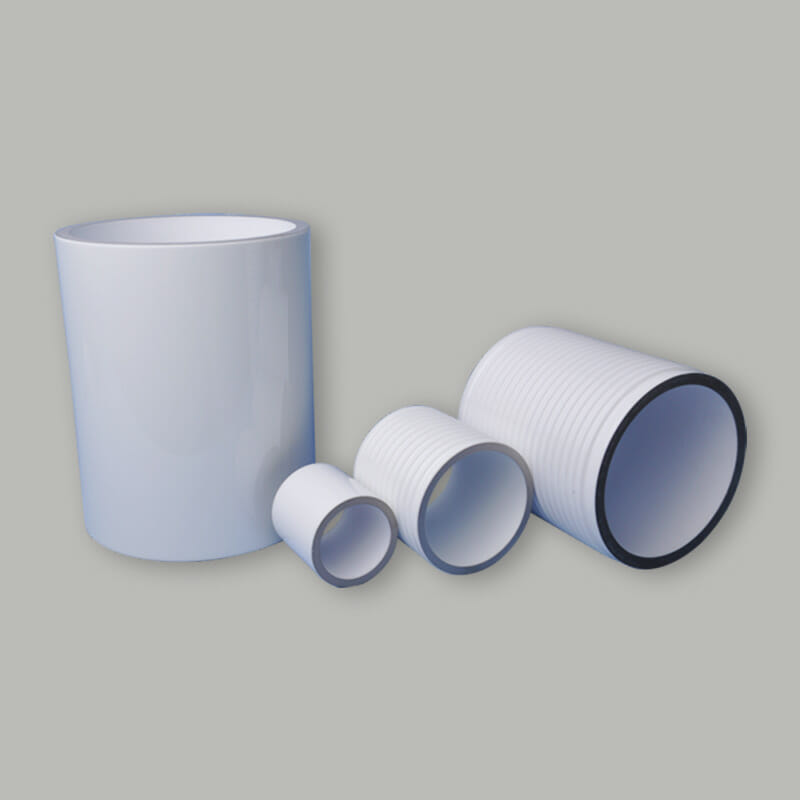

At Great Ceramic, we leverage decades of precision ceramic machining expertise to deliver high-purity alumina ceramics with consistent quality, dimensional accuracy, and outstanding performance. Our production capabilities cover everything from alumina ceramic tubes and rods to intricate alumina ceramic parts for highly specialized industries.

Skip to

Advantages | Applications | Material Grades | Properties | Cases | Machining | FAQs | Related

Alumina Ceramic Properties & Advantages

The alumina ceramic material properties set it apart as a leader in industrial materials:

Is Alumina Ceramic Durable?

The question "Is alumina ceramic durable?" is frequently asked by engineers and buyers alike. The answer is a resounding yes.

Thanks to its exceptional hardness, corrosion resistance, and high-temperature stability, alumina ceramics outperform metals, plastics, and glass in longevity—particularly in abrasive, high-load, and thermally extreme conditions.

Alumina Ceramic Applications

Alumina ceramics are known for their exceptional hardness and wear resistance, excellent corrosion resistance and electrical insulation properties, and can maintain stable mechanical and chemical properties under high temperatures and harsh environments. At the same time, due to their good processability and high cost-effectiveness, they are widely used in electronics, machinery, chemicals and other industries.

Forms and Grades of Alumina Ceramics

Great Ceramic offers custom-engineered alumina ceramics in a variety of grades and forms to match the needs of different industries:

96 Alumina Ceramic

96 Alumina Ceramic is a high-performance ceramic material composed of 96% aluminum oxide (Al₂O₃). Due to its excellent mechanical properties, wear resistance, and chemical stability, it is widely used in industrial manufacturing, electronics, electrical engineering, machinery, and medical fields.

Key Features

Main Application Areas

Production Process and Machining

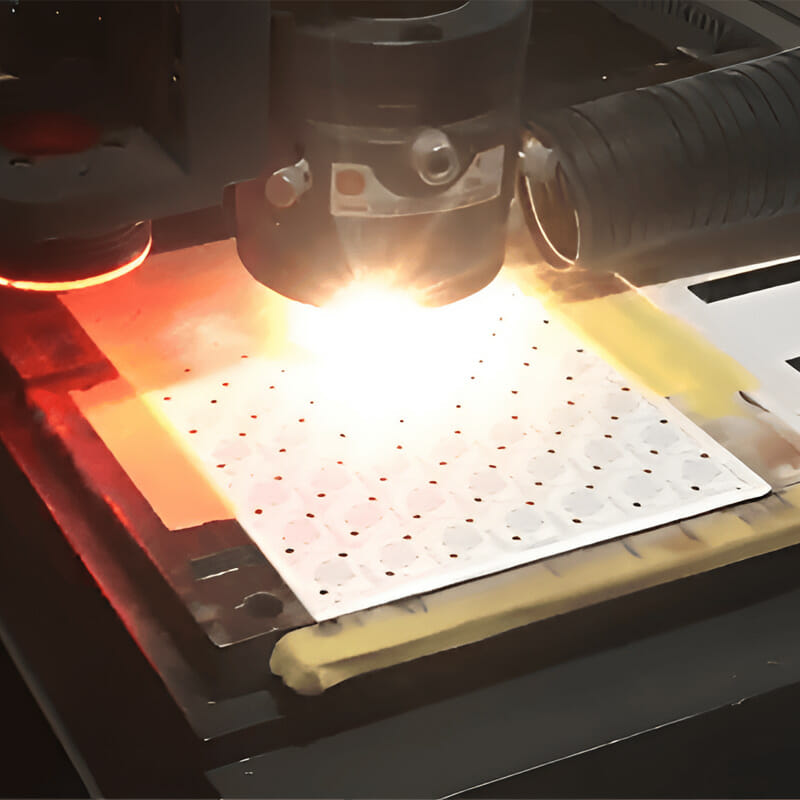

96 Alumina ceramics are typically made from high-purity alumina powder, which is compacted and sintered at high temperatures. The finished product exhibits a dense and uniform microstructure. Due to its high hardness, machining is challenging, often requiring specialized precision ceramic processing techniques such as diamond grinding and laser machining.

99 Alumina Ceramics

99 Alumina ceramics refer to high-purity ceramic materials with an aluminum oxide (Al₂O₃) content of 99%, belonging to the category of advanced ceramics. Due to its high purity, it possesses superior physical, mechanical, and electrical properties and is widely used in high-end industrial fields and precision electronic equipment.

Key Features

Main Applications

Production and Processing

99 alumina ceramics are typically manufactured from high-purity alumina powder through precision molding and high-temperature sintering. Their high density and uniform microstructure ensure excellent performance. Due to their extremely high hardness, processing generally requires diamond tools and advanced machining techniques.

99.7% Alumina Ceramics

99.7% Alumina ceramics refer to high-purity alumina ceramics with an aluminum content of approximately 99.7%. Their high chemical purity provides excellent mechanical strength, wear resistance, electrical insulation, and thermal stability, making them commonly used in high-end industrial and electronic applications where reliability, cleanliness, or electrical insulation are crucial.

Key Features

Typical Applications

Production Process and Machining

99.7 Alumina Ceramic utilizes high-purity alumina powder through advanced isostatic pressing, high-temperature sintering, and hot isostatic pressing (HIP) processes to achieve a dense and uniform material structure. Due to the material's extreme hardness, advanced machining techniques such as diamond grinding, ultrasonic machining, and laser cutting are often employed to ensure precision and surface quality.

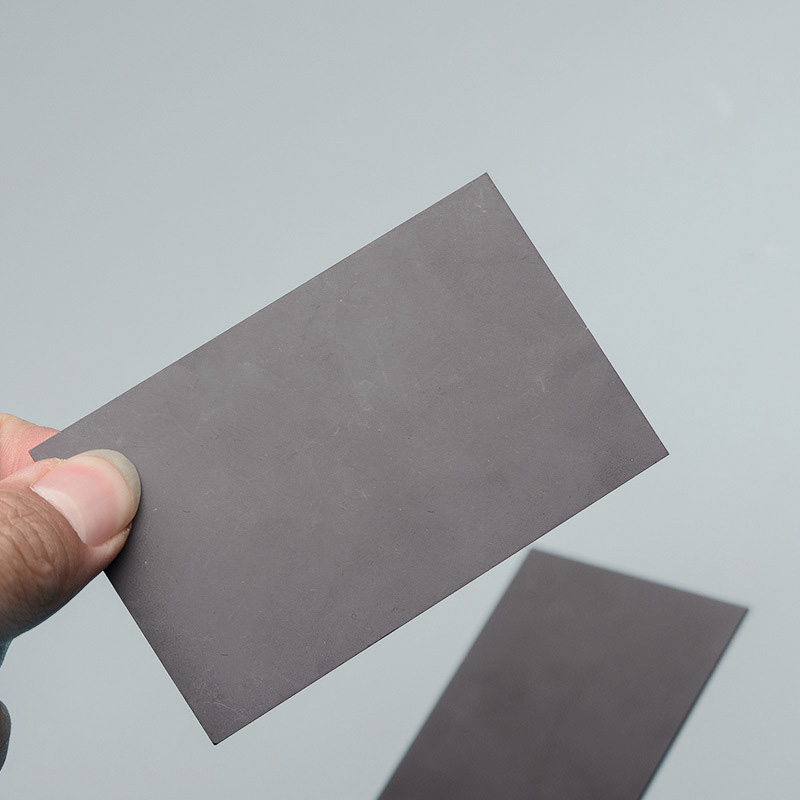

Black Alumina Ceramic Substrate

Black alumina ceramic substrates are high-performance ceramic electronic substrates made from an aluminum oxide (Al₂O₃) matrix doped with a black colorant. Due to their excellent mechanical strength, thermal stability, electrical insulation, and unique black surface properties, they are widely used in electronic packaging, heat dissipation, and high-frequency electronic devices.

Key Features

Typical Applications

Production Process

Black alumina ceramic substrates are typically made by uniformly mixing high-purity alumina powder with a black colorant, forming the substrate through dry pressing or tape casting, and then sintering it at high temperatures. The surface can be precision machined and polished to meet the stringent dimensional and surface quality requirements of electronic packaging. Some products also feature special coatings to enhance electrical performance and durability.

Alumina Ceramic Material Properties – Technical Data

The following only lists the performance parameters of the three most common aluminum oxide ceramics. Normally, alumina ceramics are composed of these types.

Mechanical

| Properties | Unit | 95%Al2O3 | 99%Al2O3 | 99.5%Al2O3 |

| Colour | —— | White | Yellow | Yellow |

| Density | g/cm³ | 3.7 | 3.85 | 3.9 |

| Hardness | GPa | 13.7 | 15.2 | 15.7 |

| Compressive Strength | MPa | 2000 | 2160 | 2350 |

| Flexural Strength | MPa | 280 | 310 | 350 |

| Fracture Toughness | MPa・m1/2 | 3~4 | 3~4 | 4.5 |

| Modulus of Elasticity | GPa | 320 | 360 | 370 |

| Poissons Ratio | —— | 0.23 | 0.23 | 0.23 |

Thermal

| Properties | Unit | 95%Al2O3 | 99%Al2O3 | 99.5%Al2O3 |

| Maximum Use Temperature | ℃(No load) | 1650 | 1650 | 1650 |

| Thermal Conductivity @ 20°C | W/(m・K) | 24 | 29 | 32 |

| Thermal Expansion a at 20–400°C | 1 x 10-6/°C | 7~8 | 7~8 | 7~8 |

| Specific Heat | J/(kg・K) | 780 | 790 | 780 |

| Thermal Shock Resistance | ℃(Put in water) | 200 | 200 | 200 |

Electrical

| Properties | Unit | 95%Al2O3 | 99%Al2O3 | 99.5%Al2O3 |

| Dielectric Constant | 1MHz | 9.4 | 9.9 | 9.9 |

| Dielectric Strength | V/m | 15 x 106 | 15 x 106 | 15 x 106 |

| Dielectric Loss | 1MHz | 4 x 10-4 | 4 x 10-4 | 4 x 10-4 |

| Volume Resistivity @ 25°C | Ω・cm | >1014 | >1014 | >1014 |

| Volume Resistivity @ 500°C | Ω・cm | >108 | >108 | >1010 |

*The values are typical material properties and may vary according to products configuration and manufacturing process. For more details, Please feel free to contact us.

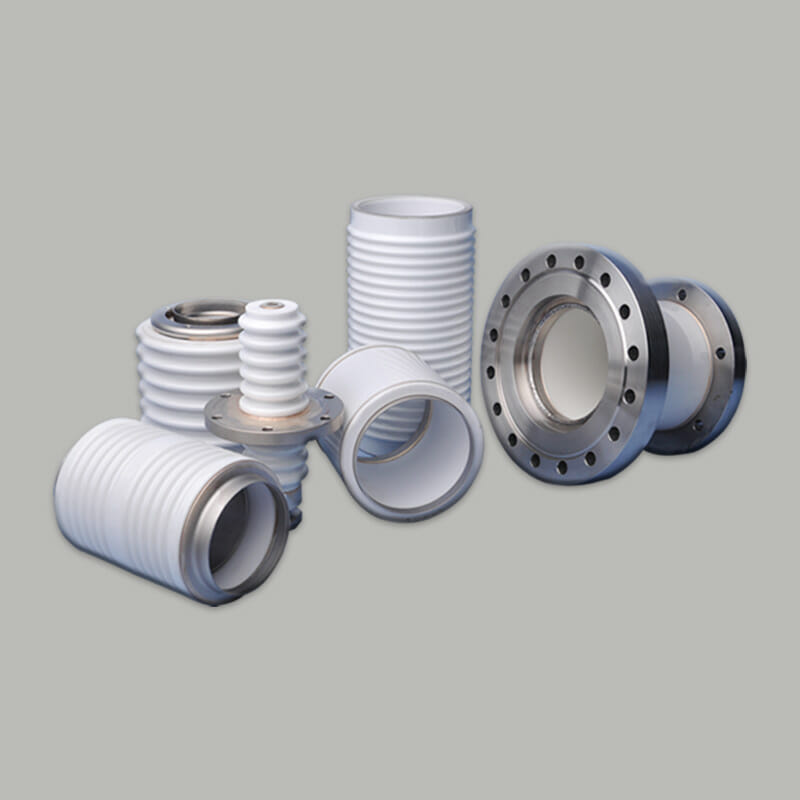

Alumina Ceramic Parts Application Cases

Alumina ceramic's outstanding combination of high hardness, excellent electrical insulation, thermal stability, and chemical resistance makes it a versatile material for numerous industrial applications. Below are some of the most common and impactful use cases of alumina ceramic parts across various sectors:

Alumina Ceramic Machining Capabilities

Great Ceramic offers alumina materials with purities ranging from 92% to 99.9%, with 99% purity being the most commonly used. Alumina can be formed using a variety of methods, including injection molding, compression molding, isostatic pressing, slip casting, and extrusion.

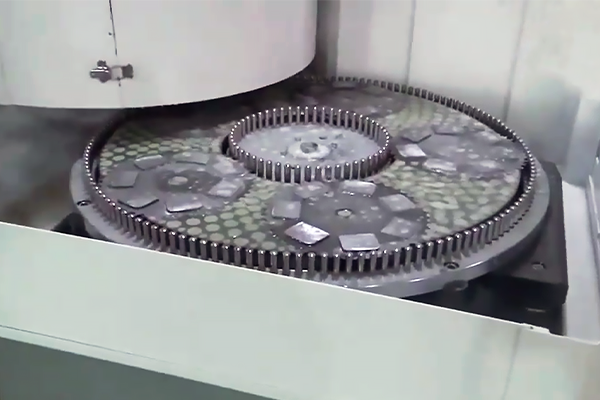

Sintering is a critical step in the manufacture of alumina ceramics. High-temperature sintering densifies the material, but it also shrinks by approximately 20%. This shrinkage makes it difficult to achieve precise final dimensions during green processing, necessitating post-sintering precision machining to achieve exacting dimensional and shape requirements. However, densely sintered alumina ceramics are extremely hard, requiring precision grinding and shaping using superhard tools such as diamond grinding.

At Great Ceramic, we have a wide range of precision ceramic processing equipment to meet the demands of manufacturing complex structures and high-precision parts.

In addition, Great Ceramic can create strong bonds between alumina and metals or other ceramic materials through metallization and brazing techniques, expanding its applications in electronics, machinery, and medical fields.

With advanced processing equipment and rich technical accumulation, we are able to provide customers with full-process solutions from material selection, design optimization to customized processing, helping to achieve high-quality alumina ceramic products.