Advanced Ceramics Materials Overview

Advanced ceramics are an advanced material, also known as engineering ceramics, technical ceramics, and precision ceramics, which have the advantages of high hardness, high strength, high temperature resistance, corrosion resistance, low density, electrical insulation, biocompatibility, and dimensional stability. Therefore, advanced ceramics are widely used as electronic materials, engineering materials, functional materials, optical materials, and medical materials.

Leading Advanced Ceramics Manufacturer

Great Ceramic is an advanced ceramics manufacturer that produces high-quality ceramics using cutting-edge technologies in advanced materials processing and advanced materials manufacturing. These processes ensure that the materials meet stringent specifications and performance standards.

Types of Advanced Ceramics Materials

Alumina (Al₂O₃)

Known for its excellent hardness and wear resistance, it exhibits good mechanical strength and electrical insulation properties at high temperatures, making it one of the most common and widely used ceramic materials.

Zirconia (ZrO₂)

Renowned for its high strength, toughness, and low thermal conductivity, it is tougher than most ceramics at room temperature, widely used in dental applications, cutting tools, and biomedical fields.

Aluminum Nitride (AlN)

Known for its high thermal conductivity and excellent electrical insulation properties, it also maintains good mechanical strength and chemical stability at high temperatures, making it an ideal material for high-performance electronics and thermal management applications.

Silicon Nitride (Si₃N₄)

Known for its excellent thermal shock resistance, mechanical strength, and wear resistance, it remains stable at high temperatures and is commonly used in turbine blades, bearings, and cutting tools, outperforming most ceramic materials.

Silicon Carbide (SiC)

Famous for its extremely high hardness and thermal conductivity, it also offers excellent chemical resistance and thermal stability, making it widely used in abrasives, refractories, and semiconductor devices, and more wear-resistant than alumina and zirconia.

Boron Nitride (BN)

Exhibits excellent thermal conductivity and electrical insulation, while also demonstrating outstanding chemical stability at high temperatures, widely used in electronic components and high-temperature furnaces, with higher thermal conductivity than alumina and silicon nitride.

Beryllium Oxide (BeO)

Possesses extremely high thermal conductivity and electrical insulation, while maintaining chemical stability at high temperatures, making it an ideal heat dissipation material in electronic devices, with higher thermal conductivity than most ceramic materials.

Machinable Glass Ceramic (MGC)

Noted for its ease of machining, this material combines good mechanical strength and electrical insulation properties, with the ability to be precisely shaped without significant thermal expansion, making it ideal for prototype development and specialized engineering applications.

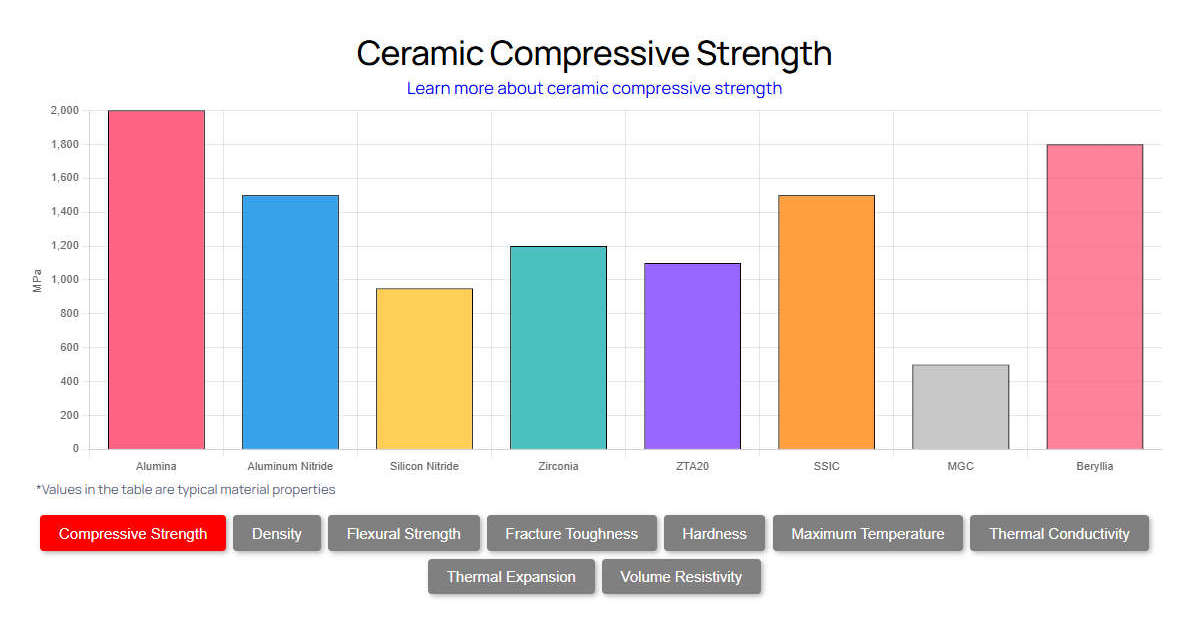

Properties of Advanced Ceramics

Engineering ceramics differ significantly in hardness, wear resistance, corrosion resistance, thermal stability, and mechanical strength. When selecting materials, customers should consider the operating environment, working conditions, stress, thermal shock, and cost to ensure the material meets application requirements and optimizes performance.

Need our help?

Not sure which ceramic material to use? Learn more about engineered ceramics, view our ceramic material comparison chart, or contact us and we’ll be happy to help.