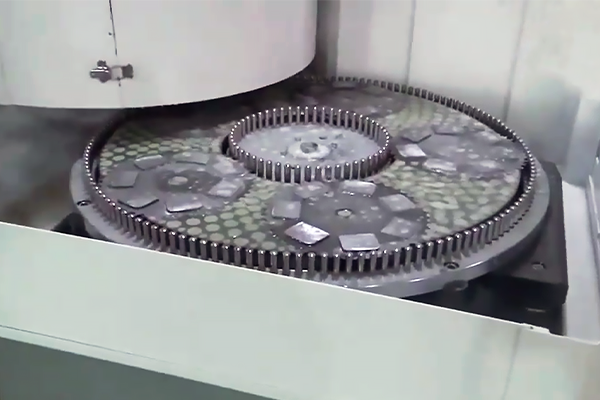

Ceramic Grinding & Polishing

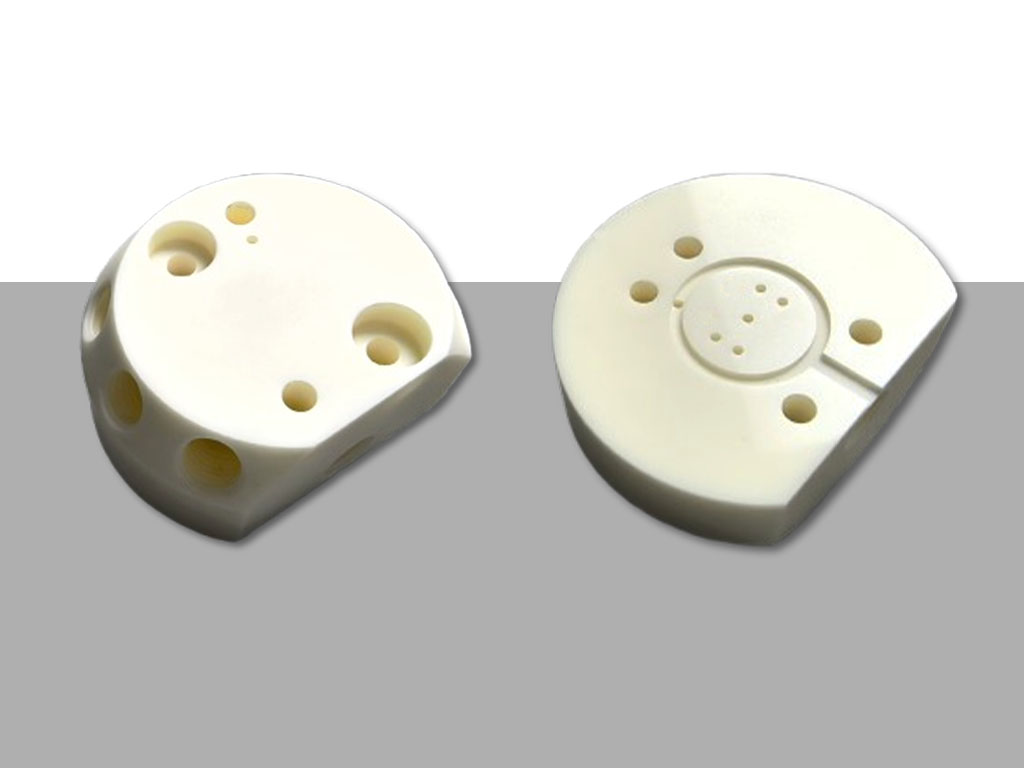

At Great Ceramic, we offer advanced ceramic grinding and polishing services tailored for high-performance applications in electronics, medical, aerospace, and more. Our expert team specializes in ceramic machining, precision surface finishing, and post-fired ceramic processing, ensuring every component achieves tight tolerances, flawless surface quality, and superior functional reliability.

Whether you're fabricating zirconia shafts, alumina insulators, or custom ceramic housings, we are your partner for consistent quality and competitive turnaround.

Why Ceramic Grinding & Polishing Is Essential

Unlike traditional materials, technical ceramics are extremely hard, chemically inert, and thermally stable—but also brittle and difficult to machine. Therefore, advanced grinding and polishing techniques are required to:

We process both green body (pre-fired) and sintered (post-fired) ceramic parts with minimal material loss and maximum finish quality.

Materials We Process

| Material | Highlights | Popular Applications |

|---|---|---|

| Alumina (Al₂O₃) | High hardness, excellent insulation | Insulators, electronics substrates |

| Zirconia (ZrO₂ / ZTA) | High toughness, wear resistance | Structural components, housings |

| Silicon Nitride (Si₃N₄) | Thermal shock resistance, high strength | Bearings, engine parts, crucibles |

| Silicon Carbide (SiC) | Ultra-hard, chemical resistance | High-temp and corrosive environment parts |

| Aluminum Nitride (AlN) | High thermal conductivity, insulation | Thermal management, semiconductor tools |

| Boron Nitride (BN) | Dry-lubricant, high-temp insulation | High-temp bearing & insulation parts |

| Beryllium Oxide (BeO) | Exceptional thermal and electrical traits | RF electronics, heat spreaders |

| Machinable Glass Ceramic | Easy to machine, ideal for prototyping | Prototyping intricate structural parts |

Our Ceramic Machining & Polishing Capabilities

| Capability | Feature | Typical Tolerance | Surface Finish |

|---|---|---|---|

| Surface grinding & polishing | Flatness and parallelism control within microns

Ideal for ceramic wafers, plates, thermal isolators |

±0.002 mm | Ra0.02 μm |

| Cylindrical and ID/OD Grinding |

Precision outer and inner diameter finishing Used for shafts, sleeves, pistons, and rods |

±0.002 mm | Ra0.02 μm |

| Centerless grinding & polishing |

High-throughput ceramic rod diameter control Excellent repeatability and production efficiency |

±0.001 mm | Ra<0.02 μm |

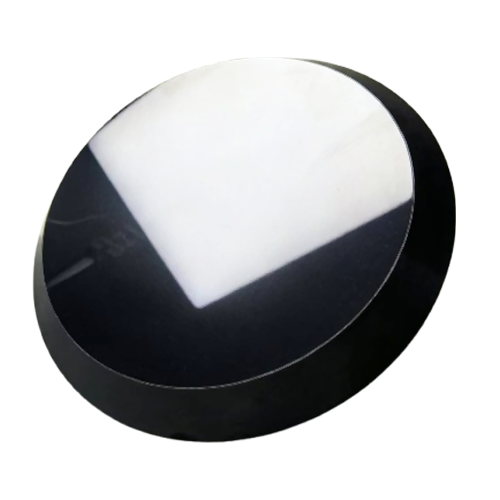

| Fine Grinding & Lapping |

Achieve sub-micron tolerance and ultra-flatness Perfect for bonding surfaces, optical windows, and sealing rings |

±0.001 mm | Ra<0.02 μm |

Why Choose Great Ceramic?

We're more than just a machining service provider—we are your trusted partner for advanced ceramic part fabrication. Here's what sets us apart:

Customer Use Cases

Frequently Asked Questions

Ready to Elevate Your Ceramic Components?

Whether you're developing next-gen electronics, precision medical devices, or aerospace-grade insulation, Great Ceramic is your trusted partner in advanced ceramic grinding and polishing.