- Home

- Technical Ceramics Category And Application

- Zirconia Toughened Alumina (ZTA) Ceramic Pumps

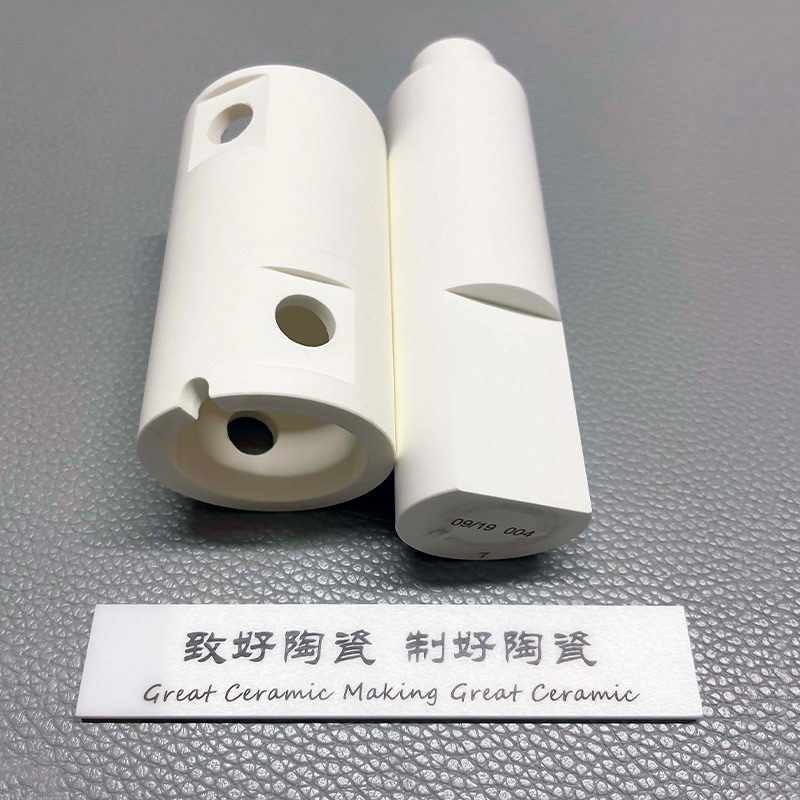

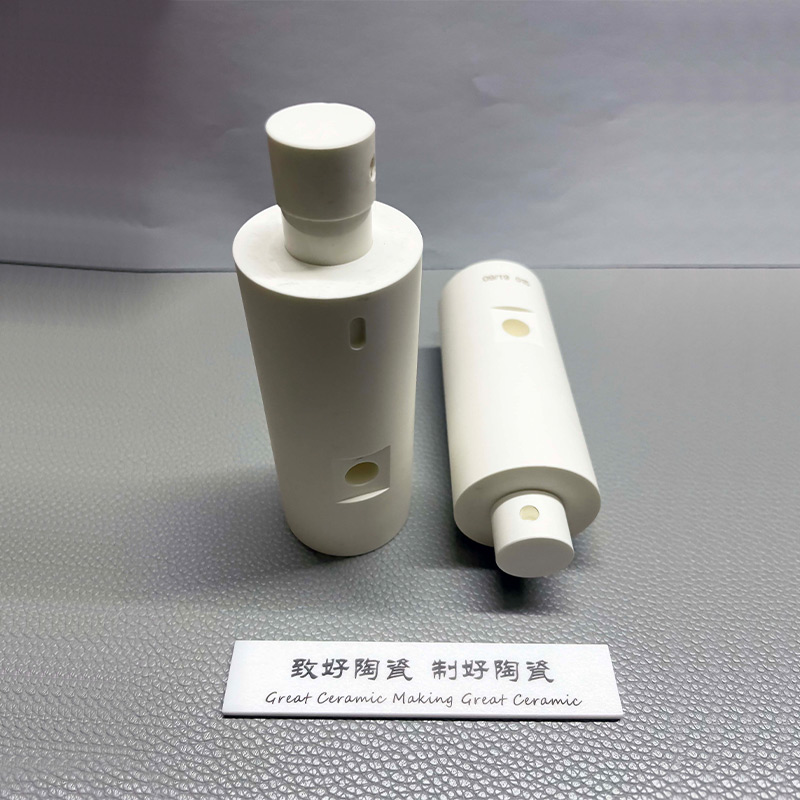

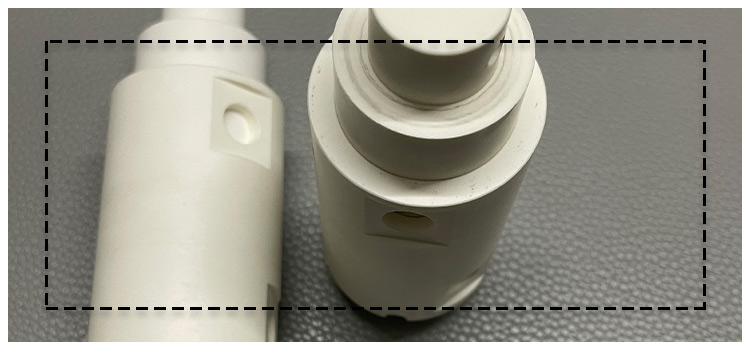

Zirconia Toughened Alumina (ZTA) Ceramic Pumps

- Can be customized according to drawings

- High strength and toughness

- Good wear resistance

- Corrosion resistance

- Biocompatibility

- Lightweight

ZTA Ceramic Pumps Introduction

ZTA ceramic pumps are made from a unique material called Zirconia Toughened Alumina, which is a composite of zirconia and alumina. This material combination provides the pumps with enhanced mechanical properties, making them suitable for use in harsh industrial environments. ZTA ceramic pumps are designed to handle various fluids, including corrosive and abrasive substances, and are capable of delivering high performance under extreme pressure and temperature conditions.

Features of ZTA Ceramic Pumps

ZTA ceramic pumps boast several distinct features that set them apart from other types of pumps. Some of their key characteristics include:

High Mechanical Strength: Zirconia Toughened Alumina pumps have exceptional mechanical strength, allowing them to operate effectively in high-pressure environments. They can handle pressures up to 20 bar, making them suitable for use in demanding industrial applications.

Excellent Wear Resistance: The presence of alumina particles in the ZTA material composition enhances the pump's wear resistance, enabling it to handle abrasive fluids and slurries without compromising performance.

Good Chemical Resistance: Zirconia Toughened Alumina ceramic pumps demonstrate remarkable chemical resistance against various aggressive chemicals, including acids and bases. This property makes them ideal for use in chemical processing applications where exposure to harsh chemicals is common.

Low Friction Coefficient: The surface of Zirconia Toughened Alumina pumps has a low friction coefficient, reducing the risk of sticking and clogging. This feature ensures smooth operation and minimizes maintenance downtime.

High Temperature Stability: Zirconia Toughened Alumina ceramic pumps can operate efficiently at high temperatures, ranging from -20°C to 200°C (-4°F to 392°F). This temperature stability makes them suitable for use in high-temperature applications, such as heat transfer systems and hot water circulation.

Dvantages of ZTA Ceramic Pump

The advantages of using ZTA ceramic pumps are numerous, and they include:

Long Service Life: Zirconia Toughened Alumina pumps have a long service life due to their high mechanical strength and excellent wear resistance. They can operate for extended periods without requiring replacement or repair, reducing maintenance costs and downtime.

Reduced Maintenance Costs: The low friction coefficient and good chemical resistance of ZTA ceramic pumps result in reduced maintenance costs. They require less frequent cleaning and maintenance compared to traditional pumps, saving time and money.

Improved Efficiency: Zirconia Toughened Alumina pumps offer improved efficiency due to their smooth operation and low power consumption. They can handle high flow rates with minimal energy input, reducing operating costs and environmental impact.

Versatility: Zirconia Toughened Alumina pumps are versatile and can be used in a variety of applications, including chemical processing, mineral processing, food and beverage production, and pharmaceutical manufacturing. Their ability to handle corrosive and abrasive fluids makes them particularly useful in challenging industrial environments

Applications of ZTA Ceramic Pumps

ZTA ceramic pumps have numerous applications across various industries, including:

Chemical Processing: ZTA ceramic pumps are widely used in chemical processing plants to transport corrosive and abrasive fluids. Their excellent chemical resistance and wear resistance make them ideal for handling sulfuric acid, hydrochloric acid, and other aggressive chemicals.

ineral Processing: In mineral processing, ZTA ceramic pumps are used to transport slurries and suspensions containing abrasive particles. Their high wear resistance and low friction coefficient enable them to handle these materials efficiently and reliably.

Food and Beverage Production: ZTA ceramic pumps are employed in food and beverage production to handle liquids and slurries. Their non-stick surface and easy cleanability make them perfect for applications involving hygiene-sensitive products.

Pharmaceutical Manufacturing: In pharmaceutical manufacturing, ZTA ceramic pumps are utilized to transport sensitive drugs and active pharmaceutical ingredients. Their biocompatibility and chemical resistance ensure that the purity and efficacy of the final product are maintained.

Zirconia Ceramics Supply Company

Great Ceramic has been engaged in the work of precision technical ceramics for many years, and has rich experience in the milling, grinding and polishing of Zirconia(ZrO2) Ceramics. We can:

- Make products according to the requirements of the drawings;

- Manufacturing more complex products;

- Achieve higher dimensional accuracy;

- Realize quick response and delivery;

- Provide more professional services.

Great Ceramic can improve all tolerances according to the size and structure of precision advanced ceramic products. Great Ceramic is committed to ensuring that we only produce the highest quality precision ceramic parts that meet or exceed customer specifications.

Contact us to find out what we can do for you!

- We will reply to your message within 24 hours;

- We can provide you with technical consulting services;

- We support any number of product customization;

- We are happy to provide service for you.

Packing and Shipping

Great Ceramic's Zirconia Toughened Alumina (ZTA) Ceramic Pumps has been carefully processed to minimize damage during storage and transportation and maintain the quality of our products in the original state.