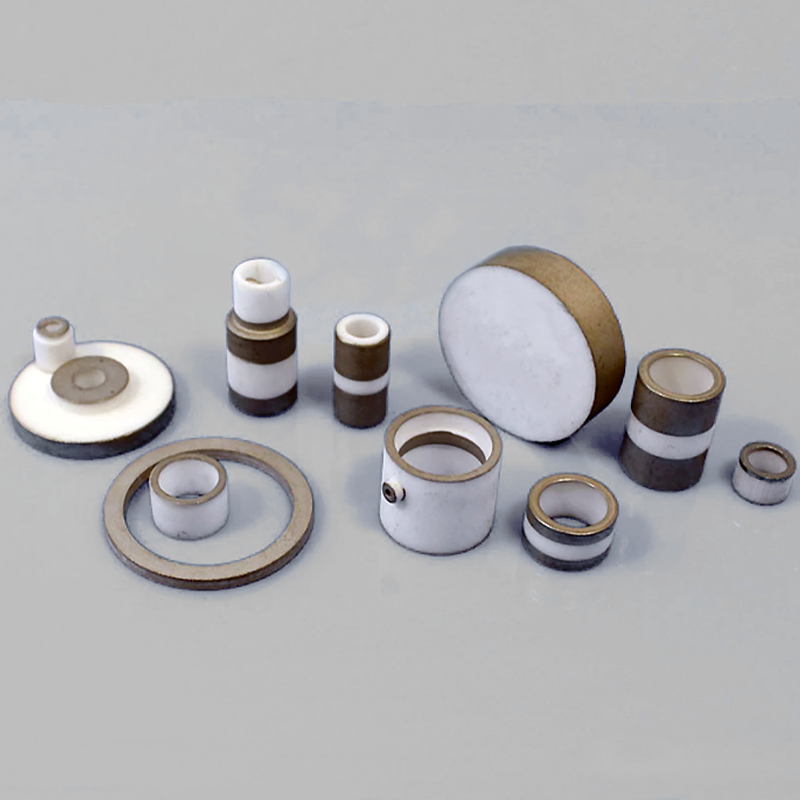

Because the surface structure of ceramic material is different from that of metal material, welding often can not wet the surface of ceramic, and can not form a firm bond with it. Therefore, the sealing of ceramic and metal is a special process method, namely metallization method: first, firmly adhere a layer of metal film on the ceramic surface, so as to realize the welding of ceramic and metal. In addition, the special glass solder can directly realize the welding of ceramic and metal.

- Stronger Bond

- Higher Precision at a Lower Cost

- Reduced Substrate Deformation

Great Ceramic has rich experience in milling, grinding and polishing precision (Advanced) ceramics and firing ceramics, which enables us to achieve:

- Provide customized service for surface metallization of fine grinding ceramics;

- The bonding strength between the metal layer and the ceramic is high, and the electrical properties are good;

- Repeatable welding;

- The thickness of the metal layer can be adjusted in the range of 1 μ M-1 mm;

- The resolution of L / s can reach 20 μ m, which can realize the through-hole connection directly;

- Provide customized solutions for customers;

- Please contact us for further details on surface metallization.

All tolerances can be improved upon depending on the size, shape & geometry of the precision ceramic part. Great Ceramic is dedicated to ensuring we make only the highest quality parts that meet or exceed our customers specifications.

Great Ceramic has accumulated many years of experience in the pursuit of developing the best precision (Advanced) ceramic parts in the world, and is constantly applying this knowledge every day. In fact, we have been involved in the production of precision ceramics by many customers.

Contact us to find out what we can do for you.

- We can reply to your inquiry within 24 hours (except on Saturdays and Sundays);

- We can provide customized product service for you;

- We can accept the customized service of 1 product.