- Home

- Technical Ceramics Category And Application

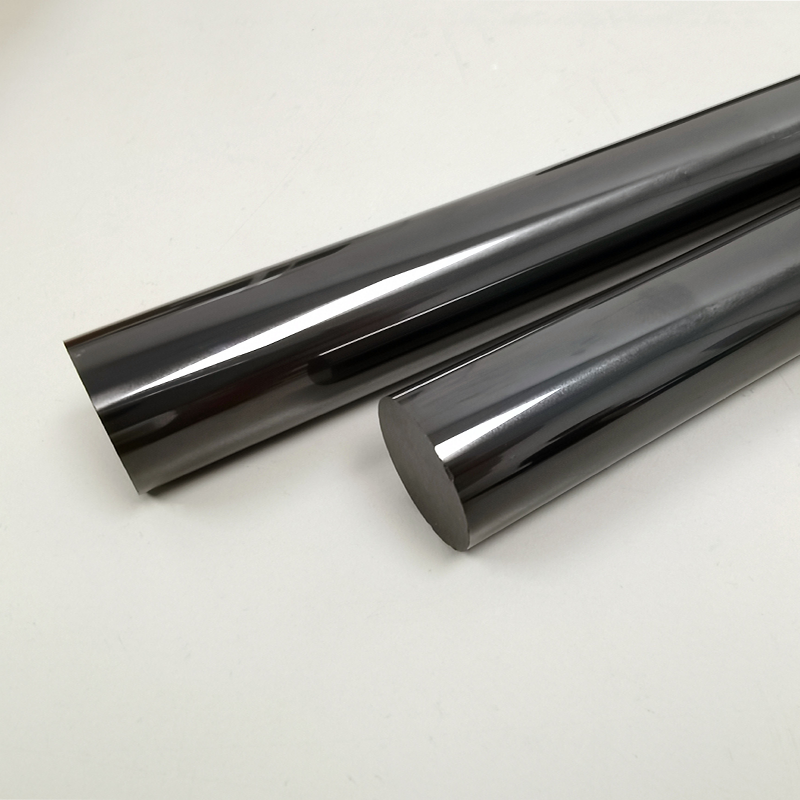

- Silicon nitride ceramic high pressure plunger

Silicon nitride ceramic high pressure plunger

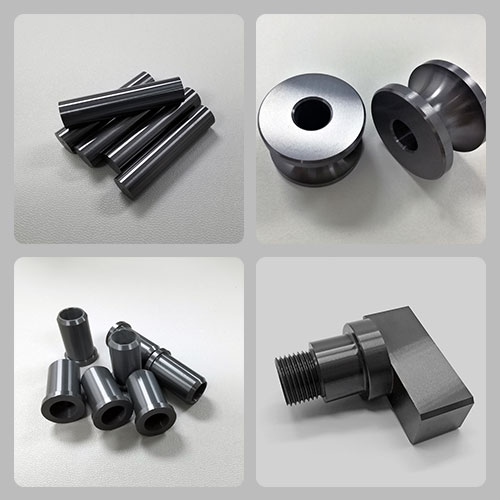

- Shape and size can be customized according to requirements

- Vickers Hardness(HV50): 14(Gpa)

- Very low density (3.21 g/cm³)

- Excellent thermal shock resistance: high thermal stress parameters (569 K)

- Maximum operating temperature in oxidizing atmosphere: 1200 ° C

Silicon Nitride

Si3N4

Silicon nitride is mainly composed of Si3N4, which has excellent heat shock resistance and high temperature strength. These characteristics make it an ideal material for automobile engine and gas turbine. It can be used in turbocharger rotor, hot plug and hot plug in diesel engine, as well as in many other applications.

Silicon Nitride has the most versatile combination of mechanical, thermal, and electrical properties of any technical ceramic material. It is a high performance technical ceramic that is extremely hard and has exceptional thermal shock and impact resistance. It surpasses most metals high temperature capabilities and has a superior combination of creep and oxidation resistance. Additionally, its low thermal conductivity and high wear resistance make it an excellent material that can withstand the toughest of conditions in the most demanding industrial applications. Silicon Nitride is an excellent choice when high-temperature and high-load abilities are needed.

Feature

Very low density (3.21 g/cm³)

Very high fracture toughness (7 MPam1/2)

Good bending strength (850 MPa)

Excellent thermal shock resistance: high thermal stress parameters (569 K)

Maximum operating temperature in oxidizing atmosphere: 1200 ° C

Maximum operating temperature in neutral atmosphere: 1600 ° C)

Structure

Great Ceramic has rich experience in milling, grinding and polishing precision (Advanced) ceramics and firing ceramics, which enables us to achieve:

- Shape and size can be customized according to requirements;

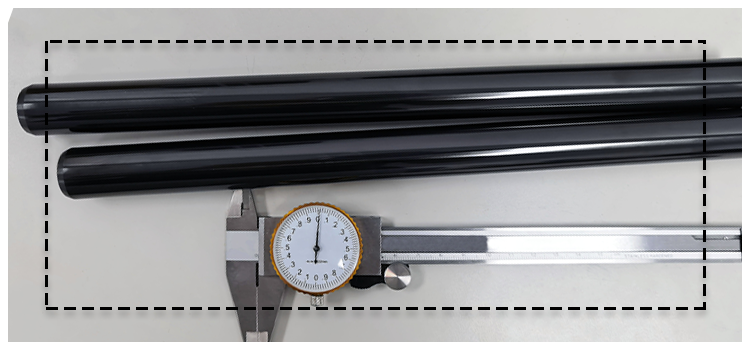

- When the accuracy of ceramic outer diameter is the best, it can reach ± 0.002mm, generally ± 0.005mm;

- The surface roughness can reach ra0.02um after polishing and ra0.4um under fine grinding condition;

- For further details of the structure, please contact us.

All tolerances can be improved upon depending on the size, shape & geometry of the precision ceramic part. Great Ceramic is dedicated to ensuring we make only the highest quality parts that meet or exceed our customers specifications.

Why Choose Us

Great Ceramic has accumulated many years of experience in the pursuit of developing the best precision (Advanced) ceramic parts in the world, and is constantly applying this knowledge every day. In fact, we have been involved in the production of precision ceramics by many customers.

Contact us to find out what we can do for you.

- We can reply to your inquiry within 24 hours (except on Saturdays and Sundays);

- We can provide customized product service for you;

- We can accept the customized service of 1 product.

Packing and Shipping