- Home

- Technical Ceramics Category And Application

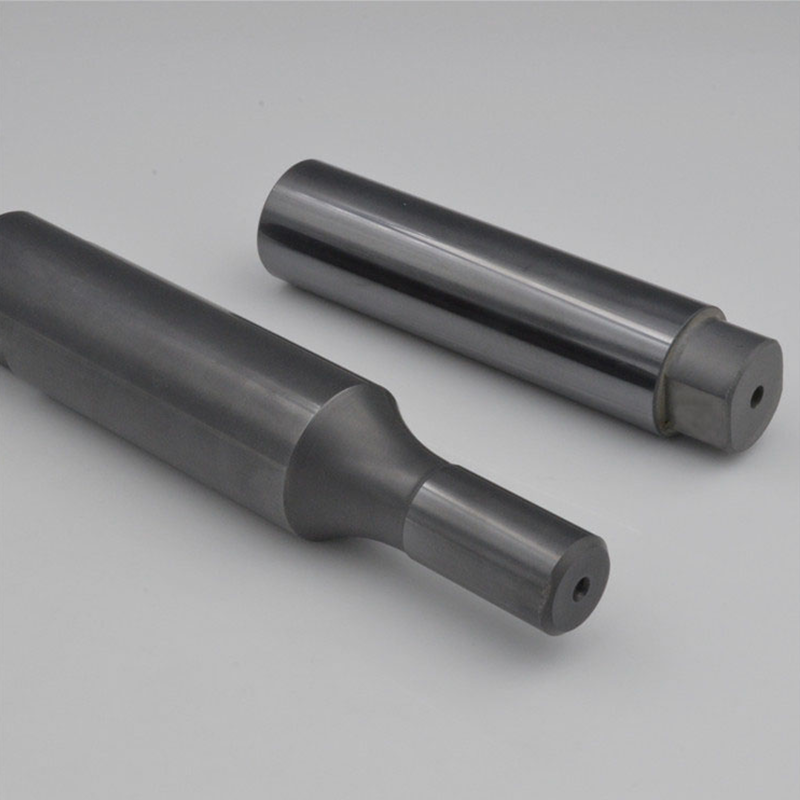

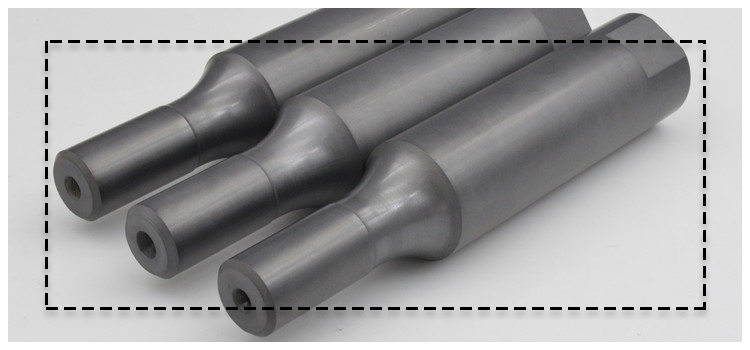

- Silicon carbide ceramic mandrel

Silicon carbide ceramic mandrel

- Shape and size can be customized according to requirements

- Very high hardness(HV10): 22.2(Gpa)

- Very low density (3.10-3.20 g/cm³)

- At temperatures up to 1400 ℃, SiC can even maintain its strength

- Because of its chemical and physical stability, SiC has high hardness and corrosion resistance.

Silicon Carbide

SiC

The properties of silicon carbide are very similar to diamond. It is one of the lightest, hardest and strongest industrial ceramic materials. The material of silicon carbide ceramics can be stable at high temperature up to 1400 ° C. Young's modulus above 400 GPA ensures excellent dimensional stability. The excellent resistance of silicon carbide to corrosion, wear and erosion is as good as its ability to withstand friction and wear.

Silicon carbide is toxicologically safe and can be used in food industry. Another typical application of silicon carbide components is the use of friction bearing dynamic sealing technology and mechanical seals, such as in pumps and transmission systems. When used with active high temperature media, SiC can achieve extremely economical solutions and longer tool life than metals. SiC ceramics are also very suitable for the harsh conditions in ballistic missiles, chemical production, energy technology, papermaking, and as pipeline system components.

Feature

Low density (3.10 to 3.20 g/cm3)

High hardness (HV10 ≥ 22 GPA)

High Young's modulus (380 to 430 MPa)

Corrosion and wear resistance even at high temperatures

Toxicological safety

Structure

Great Ceramic has rich experience in milling, grinding and polishing precision (Advanced) ceramics and firing ceramics, which enables us to achieve:

- Shape and size can be customized according to requirements;

- When the outer diameter accuracy of cylindrical products is the best, it can reach ± 0.002mm, which is generally controlled within ± 0.05mm;

- When the accuracy of cylindrical product inner hole is the best, it can reach ± 0.005mm, which is generally controlled within ± 0.05mm;

- Products can be added according to the needs of holes and grooves, arcs, threads and other structures

- The surface roughness of silicon carbide ceramics can reach ra0.02um after polishing, and ra0.4um under fine grinding condition;

- For further details of the structure, please contact us.

All tolerances can be improved upon depending on the size, shape & geometry of the precision ceramic part. Great Ceramic is dedicated to ensuring we make only the highest quality parts that meet or exceed our customers specifications.

Why Choose Us

Great Ceramic has accumulated many years of experience in the pursuit of developing the best precision (Advanced) ceramic parts in the world, and is constantly applying this knowledge every day. In fact, we have been involved in the production of precision ceramics by many customers.

Contact us to find out what we can do for you.

- We can reply to your inquiry within 24 hours (except on Saturdays and Sundays);

- We can provide customized product service for you;

- We can accept the customized service of 1 product.

Packing and Shipping