- Home

- Technical Ceramics Category And Application

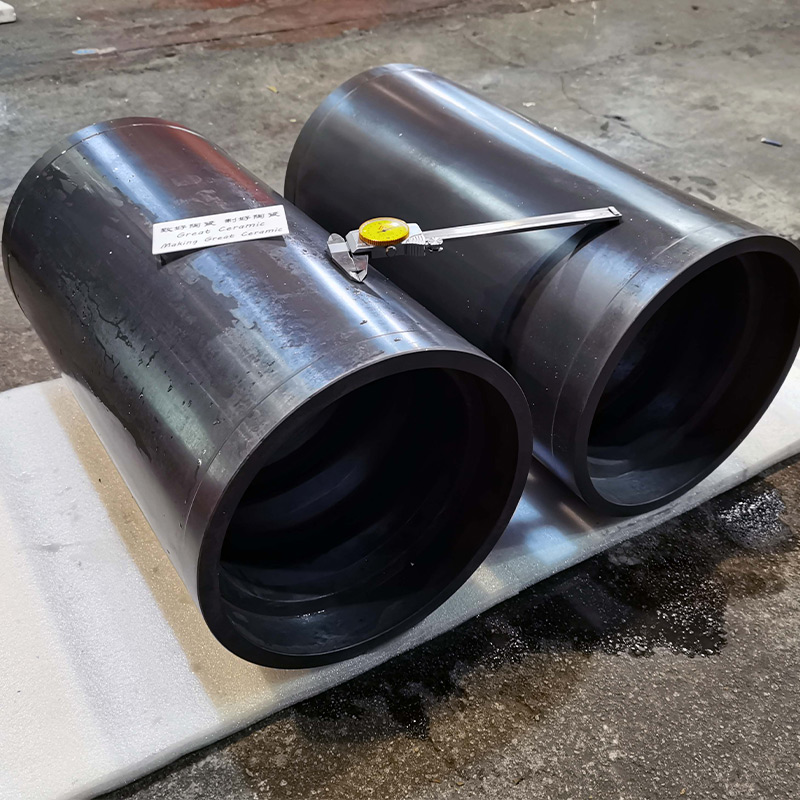

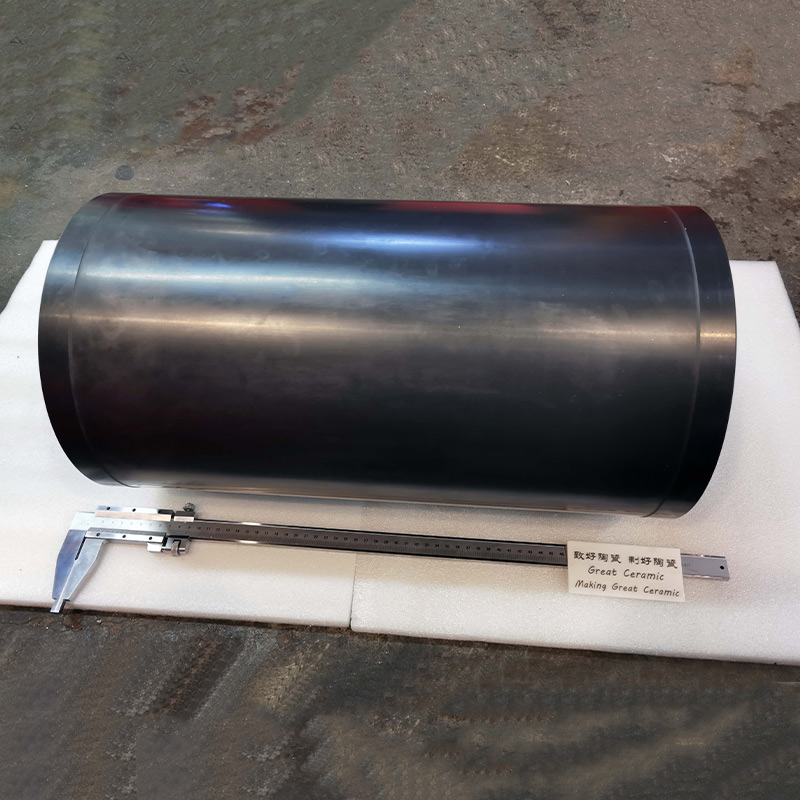

- Silicon Carbide Ceramic Inner Sleeve(Lining)

Silicon Carbide Ceramic Inner Sleeve(Lining)

- Can be customized according to requirements;

- Can make very complex structures;

- It can be used at 1400 ℃;

- High hardness, very wear-resistant;

- High corrosion resistance;

About SiC Ceramic Inner Sleeves

Silicon carbide ceramic inner sleeves are widely used in powder grinding beds, ball mills, crushing equipment and other fields. It is made of high-purity silicon carbide powder and other raw materials through pressing, sintering, and finally mechanical processing. It has excellent properties such as high hardness, high strength, corrosion resistance and high temperature resistance.

Advantages of SiC Ceramic Internal Sleeves

Silicon carbide ceramic internal sleeves has many good properties, such as high strength in a wide temperature range, good thermal shock resistance, good wear resistance and chemical corrosion resistance, and it will not deform, soften or loosen after long-term use at high temperatures It can expand and maintain the inherent high thermal conductivity of silicon carbide. This product is used in various furnaces, which can save energy, increase production and improve economic benefits.

- Good wear resistance: Silicon carbide ceramics is a high-hardness, high-strength material that can withstand greater wear and impact, so it can effectively prolong the service life when used in the inner lining of the grinding machine.

- Strong corrosion resistance: Silicon carbide ceramics have good acid and alkali corrosion resistance and are not easily corroded by chemicals, so they can be used in harsh environments.

- Good thermal stability: Silicon carbide ceramics have a high maximum service temperature (about 1400 ° C), small thermal expansion coefficient, good thermal stability, and are not easy to deform or crack, so they are suitable for high temperature applications.

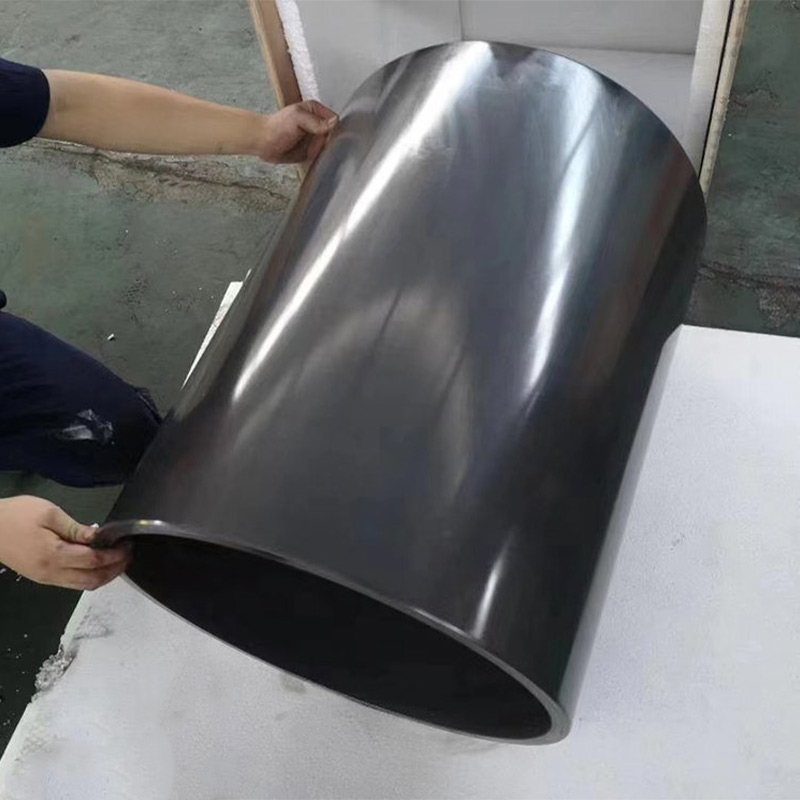

- Low friction coefficient: Silicon carbide ceramics have a high surface finish, low friction coefficient, and are not easy to generate dust, so there is little pollution to the ground material.

The Production Characteristics Of SiC Grinding Lining

- Can be customized with a maximum outer diameter of 1200mm and a height of 2000mm (current equipment capacity)

- The end face can be finely ground for the sealing surface, with an accuracy of 0.01mm

- The highest surface roughness Ra0.2um

- Strict dimensional inspection and surface fluorescence penetrant inspection are carried out at the factory

- Density greater than 3.14g/cm³

- The hardness is above 22GPa, very wear-resistant

- It can meet the requirements of food-grade medium transportation

Silicon Carbide Ceramic Inner Sleeve Manufacturer

Great Ceramic has been engaged in precision technical ceramics for many years, and has rich experience in milling, grinding and polishing silicon carbide(SIC) ceramics. We can:

- Customized ceramic products according to requirements;

- Manufacturing very complex ceramic products;

- Achieve high dimensional accuracy;

- Fast response and delivery;

- Provide more professional services.

Great Ceramic can improve all tolerances according to the size and structure of precision advanced ceramic products. Great Ceramic is committed to ensuring that we only produce the highest quality precision ceramic parts that meet or exceed customer specifications.

Contact us to find out what we can do for you!

- We will reply to your message within 24 hours;

- We can provide you with technical consulting services;

- We support any number of product customization;

- We are happy to provide service for you.

Packing and Shipping

Great Ceramic's SiC Ceramic Inner Sleeve will be packed in cartons and foam cotton before shipment to minimize damage during storage and transportation and maintain the original quality of the product.