- Home

- Technical Ceramics Category And Application

- Magnesium Oxide Stabilized Zirconia Ceramic Tiles

Magnesium Oxide Stabilized Zirconia Ceramic Tiles

- Customizable

- Unmatched Wear Resistance

- Superior Strength

- Exceptional Thermal Shock Resistance

- Corrosion Resistance

- Low Thermal Conductivity

What are Magnesium Stabilized Zirconia Ceramic?

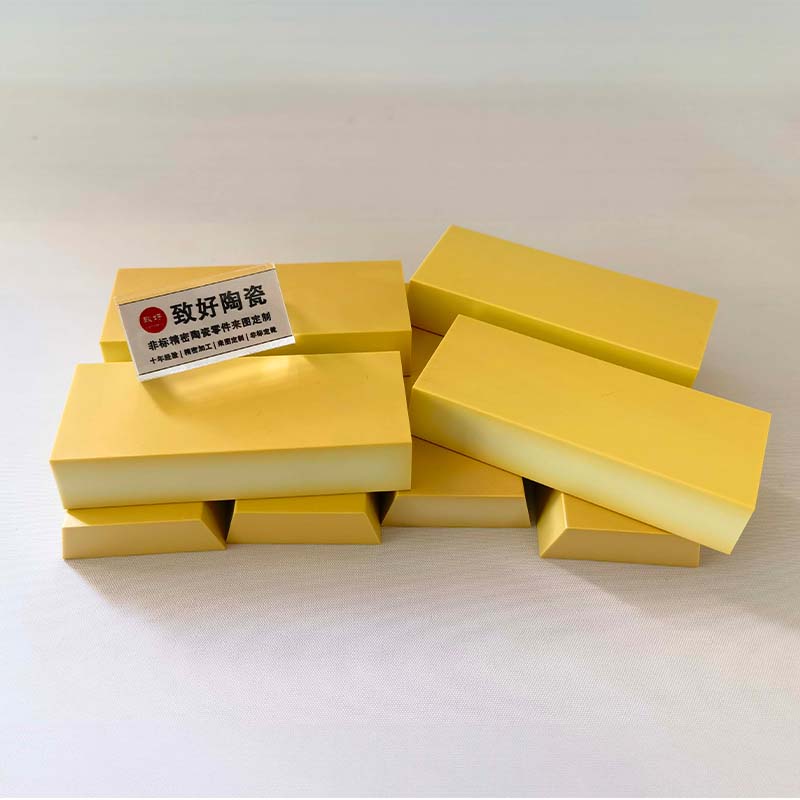

Magnesium Oxide Stabilized Zirconia Ceramic Tiles, also known as Magnesia Stabilized Zirconia (MSZ), are made from Zirconia (ZrO2), which is stabilized with Magnesium Oxide (MgO). This combination results in a ceramic material that can withstand temperatures up to 2200°C. The tiles are yellow in color, with a density ranging from 4.6 to 5.6 g/cm³.

Magnesium Stabilized Zirconia Performance Description

- Unmatched Strength and Hardness: MgO-ZrO2 tiles boast exceptional strength, exceeding that of steel and rivaling diamond in hardness. This translates to superior wear resistance, minimizing abrasion, chipping, and cracking, even in harsh environments.

- Exceptional Thermal Stability: MgO-ZrO2 exhibits remarkable thermal stability, withstanding extreme temperatures exceeding 2000°C (3632°F) without compromising its integrity. This makes it ideal for high-temperature applications, preventing thermal shock and ensuring dimensional stability.

- Chemical Inertness: MgO-ZrO2 tiles are highly resistant to a wide range of chemicals, including acids, alkalis, and solvents. This makes them ideal for applications requiring chemical compatibility and purity.

- Low Electrical Conductivity: MgO-ZrO2 tiles possess excellent electrical insulating properties, making them suitable for applications requiring electrical isolation and minimizing the risk of electrical leakage.

- Outstanding Biocompatibility: MgO-ZrO2 is biocompatible and non-toxic, making it safe for use in medical and food processing applications.

Industry Applications

The exceptional performance of MgO-ZrO2 ceramic tiles makes them a valuable material for various industries, including:

- Aerospace: High-temperature components, wear-resistant bearings, and thermal insulation.

- Chemical Processing: Reactor vessels, pump components, and valves.

- Textile Machinery: Wear parts, guide rollers, and nozzles.

- Metalworking: Cutting tools, dies, and furnace linings.

- Electronics: Substrate materials and electrical insulators.

- Food Processing: Wear linings, mixer blades, and conveyor belts.

- Jewelry and Decorative: High-end jewelry, watch faces, and architectural elements.

Why Choose Magnesium Stabilized Zirconia?

Magnesium oxide stabilized zirconia ceramic tiles are a versatile material that offers numerous benefits, including high thermal insulation, corrosion resistance, mechanical strength, and biocompatibility. They are manufactured using advanced technology and high-quality raw materials, ensuring consistent quality and reliability. Our tiles are available in various shapes, sizes, and thicknesses to meet the specific requirements of our clients.

Zirconia Ceramics Supply Company

Great Ceramic has been engaged in the work of precision technical ceramics for many years, and has rich experience in the milling, grinding and polishing of Zirconia(ZrO2) Ceramics. We can:

- Make products according to the requirements of the drawings;

- Manufacturing more complex products;

- Achieve higher dimensional accuracy;

- Realize quick response and delivery;

- Provide more professional services.

Great Ceramic can improve all tolerances according to the size and structure of precision advanced ceramic products. Great Ceramic is committed to ensuring that we only produce the highest quality precision ceramic parts that meet or exceed customer specifications.

Packing and Shipping

Great Ceramic’s magnesium stabilized zirconia ceramic tiles has been carefully processed to minimize damage during storage and transportation and maintain the quality of our products in the original state.