- Home

- Technical Ceramics Category And Application

- Machinable ceramic parts precision machining

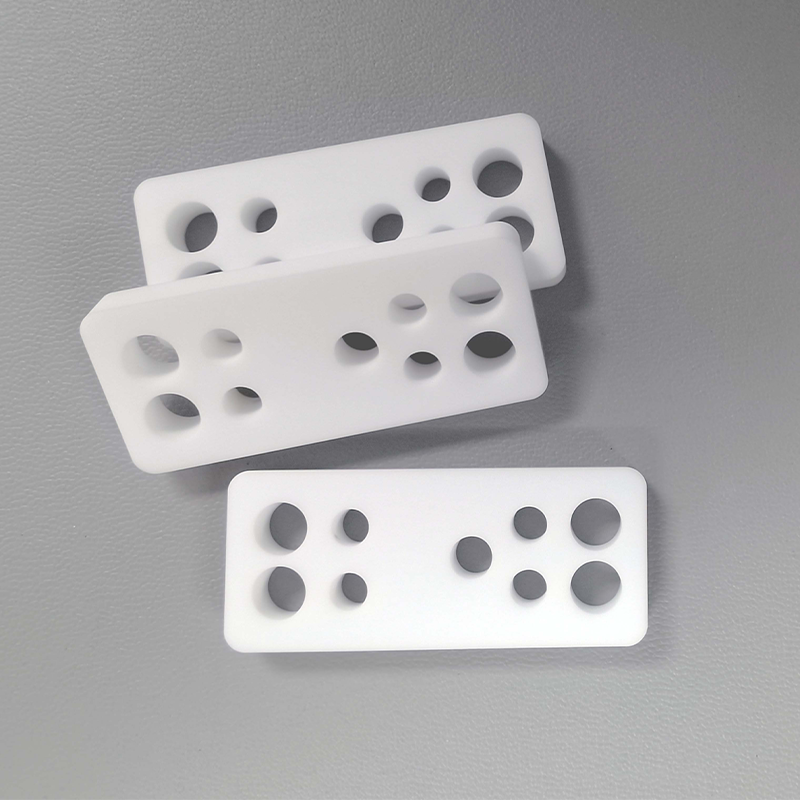

Machinable ceramic parts precision machining

- Machinable ceramic parts have good vacuum performance, electrical insulation performance, high temperature resistance, chemical corrosion resistance and other excellent properties.

Advantages Of Machinable Ceramic Parts

Machinable ceramic parts have good vacuum performance, electrical insulation performance, high temperature resistance, chemical corrosion resistance and other excellent properties.

Machinable ceramics have been widely used in industries such as automobiles, military industry, aerospace, precision instruments, medical equipment, electric vacuum devices, electron beam exposure machines, textile machinery, sensors, mass spectrometers and energy spectrometers due to their excellent properties.

Machinable Ceramic Parts Applications

The most prominent feature of machinable glass ceramics is that they can be processed with standard metal processing tools and equipment, which are unmatched by general precision ceramic materials such as alumina and silicon nitride. The processing performance of machinable ceramics is similar to that of cast iron, and it can be processed into various products with complex shapes and high precision requirements. Therefore, machinable ceramic products are an ideal choice for many industries, such as:

- Precision coil former

- High voltage insulator

- Gaskets, cavities and reflectors in laser components

- Coil support and vacuum feedthrough

- Supports and components

- Fixing device and reference block in power generation device

Machinable Glass Ceramics Basic Information

Machinable ceramic materials have excellent electrical insulation properties (electrical breakdown reaches 40KV/A per millimeter), high mechanical strength, and resistance to rapid cold and heat. Therefore, they are widely used in welding fixtures, optical glass forming molds, etc. Its corrosion resistance is also better than ordinary ceramics, and its excellent corrosion resistance makes it used in various chemical equipment. Compared with PTFE, it is more corrosion resistant, does not age, and has a long service life.

-

Excellent processability characteristics;

-

Excellent high temperature electrical insulation performance;

-

Excellent thermal shock resistance;

-

Ultra-low vacuum outgassing rate;

-

Excellent corrosion resistance;

-

Lower density.

Machinable Ceramic Supply Company

Great Ceramic has been engaged in the work of precision technical ceramics for many years, and has rich experience in the milling, grinding and polishing of machinable(MACOR®& MCREA®) ceramic. We can:

- Make products according to the requirements of the drawings;

- Manufacturing more complex products;

- Achieve higher dimensional accuracy;

- Realize quick response and delivery;

- Provide more professional services.

Great Ceramic can improve all tolerances according to the size and structure of precision advanced ceramic products. Great Ceramic is committed to ensuring that we only produce the highest quality precision ceramic parts that meet or exceed customer specifications.

Contact us to find out what we can do for you!

- We will reply to your message within 24 hours;

- We can provide you with technical consulting services;

- We support any number of product customization;

- We are happy to provide service for you.

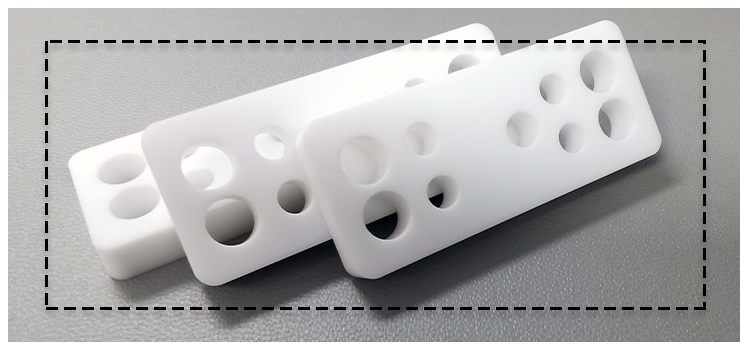

Packing and Shipping

Great Ceramic's machinable ceramic parts has been carefully processed to minimize damage during storage and transportation and maintain the quality of our products in the original state.