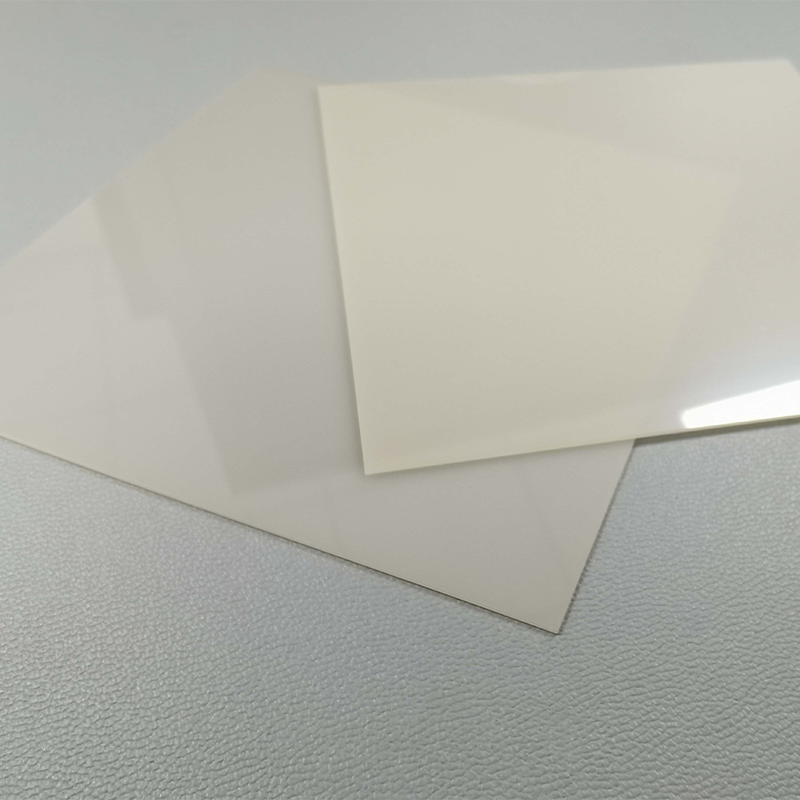

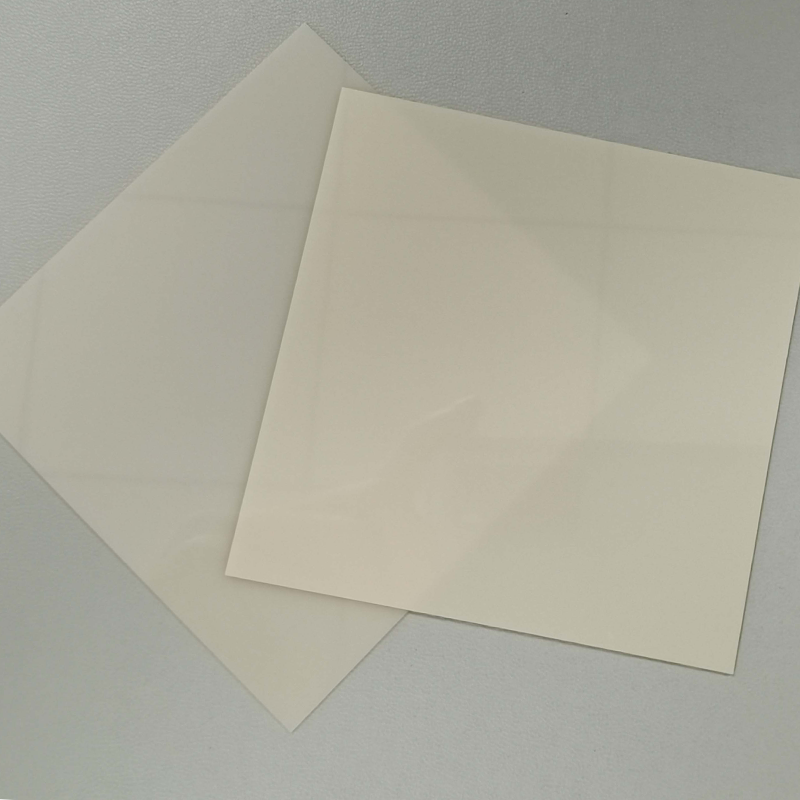

Aluminum nitride can be stabilized up to 2200 ℃. The strength at room temperature is high, and the strength decreases slowly with the increase of temperature. It has good thermal conductivity and small coefficient of thermal expansion, so it is a good thermal shock resistant material. It is an ideal crucible material for melting and casting pure iron, aluminum or aluminum alloy. Aluminum nitride is also an electrical insulator with good dielectric properties. It is also promising to be used as electrical components.

The thermal conductivity is high (more than 150W / m · K), close to BeO and SiC, more than 5 times of that of Al2O3;

The thermal expansion coefficient (4.5 × 10-6 ℃) matches that of Si (3.5-4 × 10-6 ℃) and GaAs (6 × 10-6 ℃);

Various electrical properties (dielectric constant, dielectric loss, bulk resistivity, dielectric strength) are excellent;

The mechanical properties are good, the flexural strength is higher than that of Al2O3 and BeO ceramics, and can be sintered under normal pressure;

non-toxic;

It can be made by tape casting. It is a promising substrate and packaging material for high power integrated circuits.

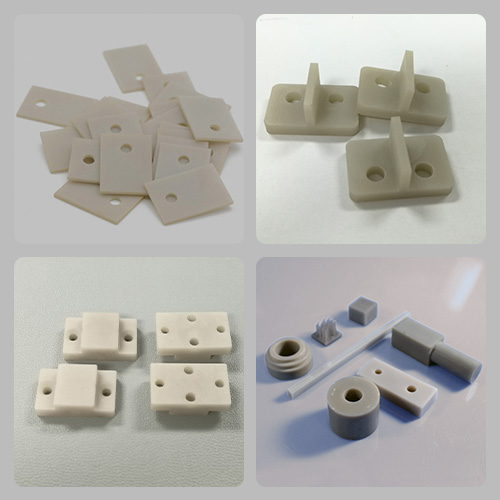

Great Ceramic has rich experience in milling, grinding and polishing precision (Advanced) ceramics and firing ceramics, which enables us to achieve:

- Shape and size can be customized

- The surface of AlN substrate can be polished;

- Laser processing can be selected according to the demand;

- For further details of the structure, please contact us.

All tolerances can be improved upon depending on the size, shape & geometry of the precision ceramic part. Great Ceramic is dedicated to ensuring we make only the highest quality parts that meet or exceed our customers specifications.

Great Ceramic has accumulated many years of experience in the pursuit of developing the best precision (Advanced) ceramic parts in the world, and is constantly applying this knowledge every day. In fact, we have been involved in the production of precision ceramics by many customers.

Contact us to find out what we can do for you.

- We can reply to your inquiry within 24 hours (except on Saturdays and Sundays);

- We can provide customized product service for you;

- We can accept the customized service of 1 product.