Magnesia Stabilized Zirconia

Magnesia Stabilized Zirconia (MSZ) is a unique ceramic material that has been engineered to meet the severe service needs of many industries. This transformation-toughened zirconia offers superior strength, toughness, and wear & corrosion resistance.

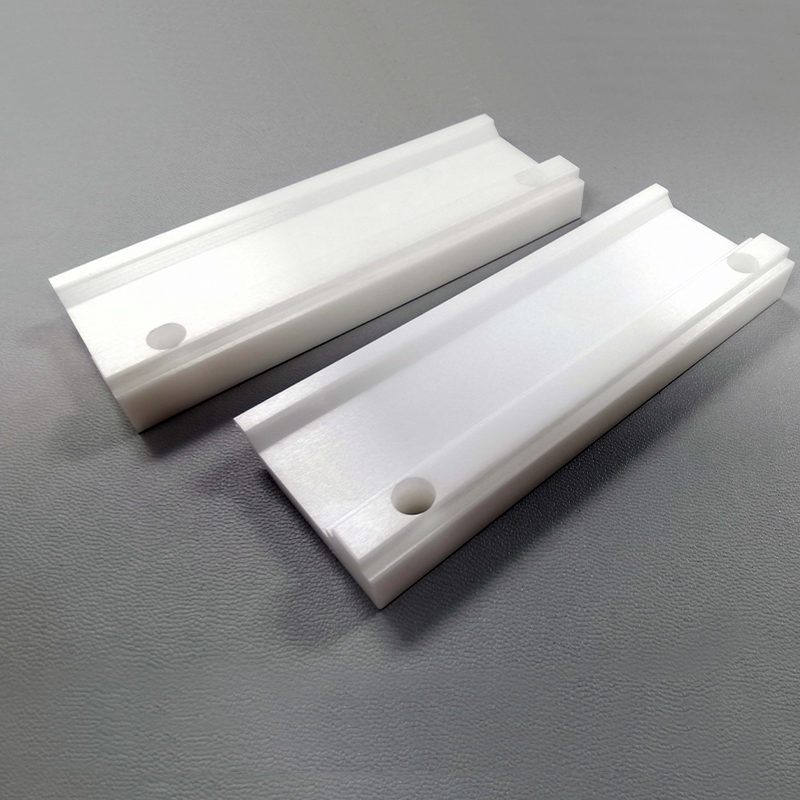

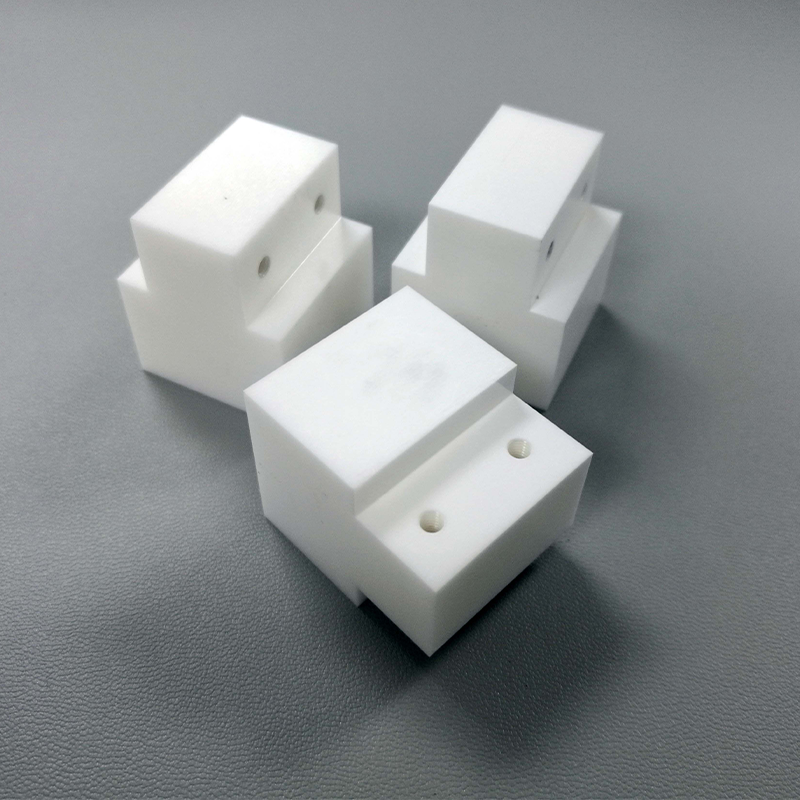

Machining Zirconia Ceramic

Great Ceramic offers custom machining services for magnesium oxide stabilized zirconia materials, our materials offer exceptional strength, durability and thermal stability.In addition, we also provide processing of black zirconia, zirconia toughened alumina, yttria stabilized zirconia and other zirconia products.

Unique Properties of MSZ

MSZ exhibits several unique properties that make it stand out among other ceramic materials. It has superior resistance to thermal shock and erosion. Additionally, it has low thermal expansion properties and excellent non-wetting characteristics. These properties make MSZ a very tough ceramic used in severe-service applications.

- Exceptional Strength: MSZ boasts remarkable strength, surpassing even that of steel in certain applications. This attribute makes it an ideal choice for components subjected to intense mechanical stress.

- Exceptional Durability: MSZ exhibits exceptional resistance to wear and abrasion, far exceeding that of conventional ceramics. This property renders it a valuable asset for applications involving friction and particle erosion.

- Exceptional Thermal Stability: MSZ maintains its structural integrity over a wide temperature range, from -40°C to 2200°C. This characteristic makes it suitable for high-temperature environments and thermal shock resistance.

Properties of Magnesium Stabilized Zirconia

| Category | Project | Measured value | Unit |

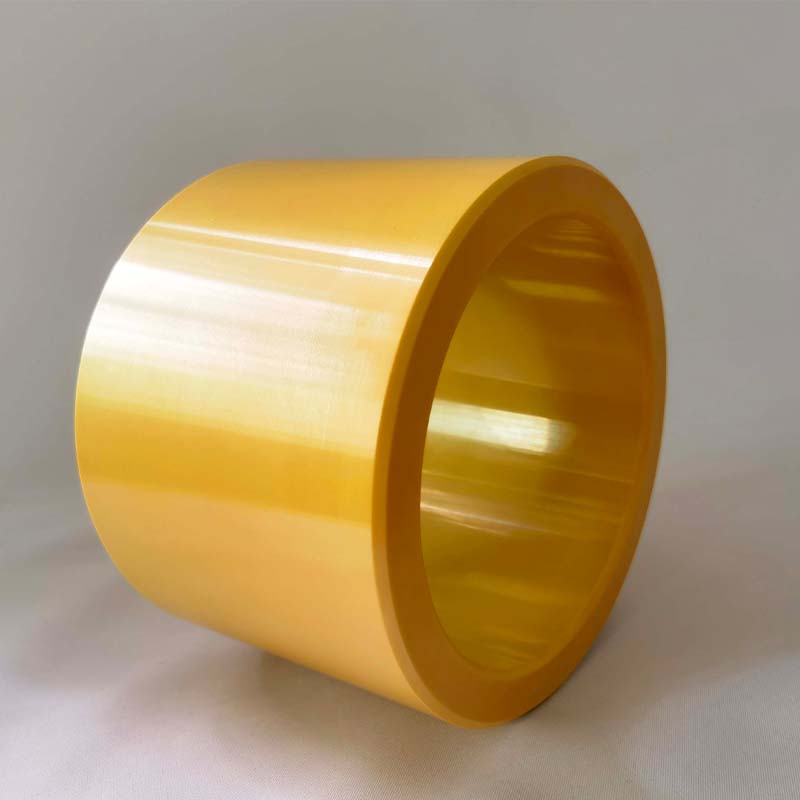

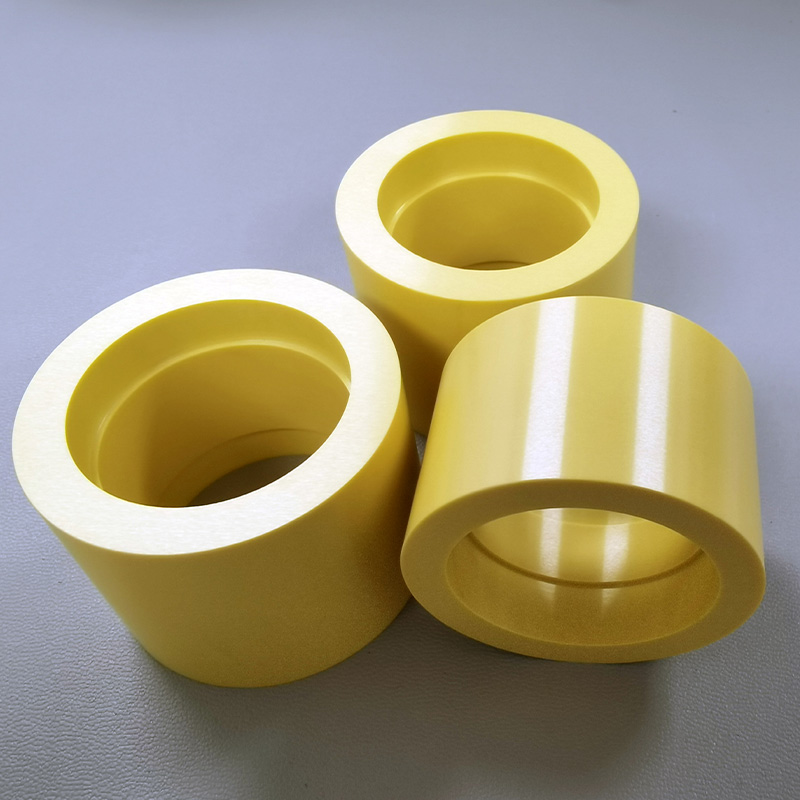

| Mechanical Properties | Color | Yellow | |

| Density | 5.7 | g/cm3 | |

| Flexural strength | 500 | MPa | |

| Compressive strength | 2500 | MPa | |

| Elastic modulus | 250 | GPa | |

| Fracture toughness | 6~7 | MPam1/2 | |

| Weber’s coefficient | 12 | M | |

| Vickers hardness | 1100 | HV0.5 | |

| Thermal Properties | Linear expansion coefficient | 10 | 10-6K-1 |

| Thermal conductivity | 3 | W/m·K | |

| Thermal shock resistance temperature (water cooling) | 450 | ∆T℃ | |

| Maximum operating temperature | 2100 | ℃ | |

| Electrical Properties | Volume resistance, 20℃ | >1014 | Ω·cm |

| Dielectric strength | 13×105 | V/m | |

| Dielectric constant | 28 | εr | |

| Dielectric loss angle, 20℃ | 0.0017 | tanδ | |

| Chemical Resistance | Nitric acid, concentration 60%, 90℃ | 0.1 | WTLossmg/cm2/day |

| Sulfuric acid, concentration 95%, 95℃ | 0.34 | WTLossmg/cm2/day | |

| Aluminium hydroxide concentration 30%, 80℃ | 0.95 | WTLossmg/cm2/day | |

Note: Performance may vary between different production batches.

Applications of Magnesium Stabilized Zirconia

MSZ is ideal for machinery parts and valves in severe applications. Its combination of corrosion resistance, durability, and toughness make it a preferred choice for these applications. MSZ coatings have low thermal conductivity and a high melting point, making them excellent high-temperature thermal barriers. They are resistant to particle erosion in high temperatures and resist wetting of molten zinc, iron, steel, copper, and aluminum.

Why Choose Great Ceramic?

Great Ceramic stands as a leading provider of high-quality MSZ products and solutions. With extensive expertise in material science and manufacturing processes, we deliver customized MSZ components tailored to meet the specific needs of our clients.