Applications of Advanced Ceramics in the Semiconductor & Electronic

The semiconductor and electronic components industry demands materials that can operate reliably under extreme conditions—high temperatures, rapid thermal cycling, high voltages, and ultra-clean manufacturing environments. Advanced ceramics have become indispensable in this field due to their exceptional combination of mechanical strength, electrical insulation, thermal stability, and chemical inertness. Materials such as alumina (Al₂O₃), aluminum nitride (AlN), silicon nitride (Si₃N₄), zirconia (ZrO₂), beryllium oxide (BeO), and boron nitride (BN) are widely used in semiconductor processing equipment, microelectronic packaging, and high-performance electronic devices.

Key Advantages of Advanced Ceramics for Semiconductor & Electronics Applications

benefit:

Key Materials in Semiconductor & Electronics Applications

At Great Ceramic, we are committed to advancing the application of high-performance ceramics in the semiconductor and electronics industries, helping our customers achieve unprecedented levels of performance, reliability, and sustainability.

| Material | Core Properties | Typical Applications |

|---|---|---|

| Alumina (Al₂O₃) | Cost-effective, good insulation, moderate thermal conductivity | LED substrates, multilayer packages, ceramic PCBs |

| Aluminum Nitride (AlN) | High thermal conductivity, electrical insulation, CTE match with Si | Power module substrates, RF device heat spreaders |

| Silicon Nitride (Si₃N₄) | High fracture toughness, thermal shock resistance | Wafer handling arms, power electronic substrates |

| Silicon Carbide (SiC) | High strength, corrosion resistance, thermal stability | CVD chamber components, diffusion furnace liners |

| Boron Nitride (BN) | Thermal conductor + electrical insulator, machinable | Heat sinks for RF/microwave devices, interface layers |

| Machinable Glass Ceramics (MGC) | Easy precision machining, stable up to 1000°C | Prototyping parts, small-batch precision components |

| ZTA (Zirconia Toughened Alumina) | High wear resistance, improved fracture toughness | Precision guides, semiconductor handling tools |

Performance Advantages Over Metals and Plastics

| Property | Advanced Ceramics | Metals | Plastics |

|---|---|---|---|

| Thermal Conductivity | High (AlN up to 260 W/m·K) | Moderate (Cu: ~400 W/m·K) | Low (<1 W/m·K) |

| Electrical Insulation | Excellent (>10¹³ Ω·cm) | Poor | Good |

| Corrosion Resistance | Excellent | Moderate/Poor | Good |

| High-Temperature Stability | Excellent (>1000°C) | Good (500–800°C) | Poor (<200°C) |

| Wear Resistance | Excellent | Good | Poor |

Key Applications

Manufacturing Capabilities for Semiconductor-Grade Ceramics

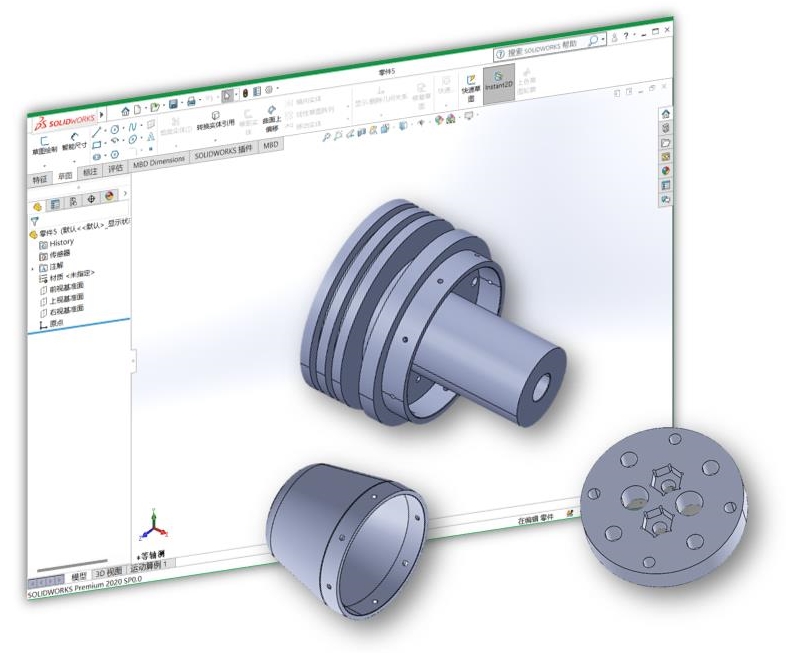

At Great Ceramic, we specialize in the custom machining of advanced ceramic components. Our precision manufacturing services ensure that each part meets exact design specifications with tight tolerances and smooth finishes. We offer:

Relevant Products

Frequently Asked Questions (FAQ)

Your trusted partner for advanced ceramics

Advanced ceramics are redefining the semiconductor and electronics industries, enabling higher power density, improved thermal management, and longer device life.

Great Ceramic offers precision machining, custom design, and metallization services to meet the demanding requirements of your electronics applications, creating custom, high-performance ceramic components.