Applications of Advanced Ceramics in the Industrial Machinery

In today's high-performance manufacturing landscape, industrial machinery is evolving rapidly to meet the demands of efficiency, precision, and durability. Advanced ceramics, also known as technical ceramics, have emerged as a key enabler of this transformation. With their unique combination of mechanical strength, thermal stability, chemical resistance, and wear performance, these materials are being widely adopted across a broad range of industrial machinery applications.

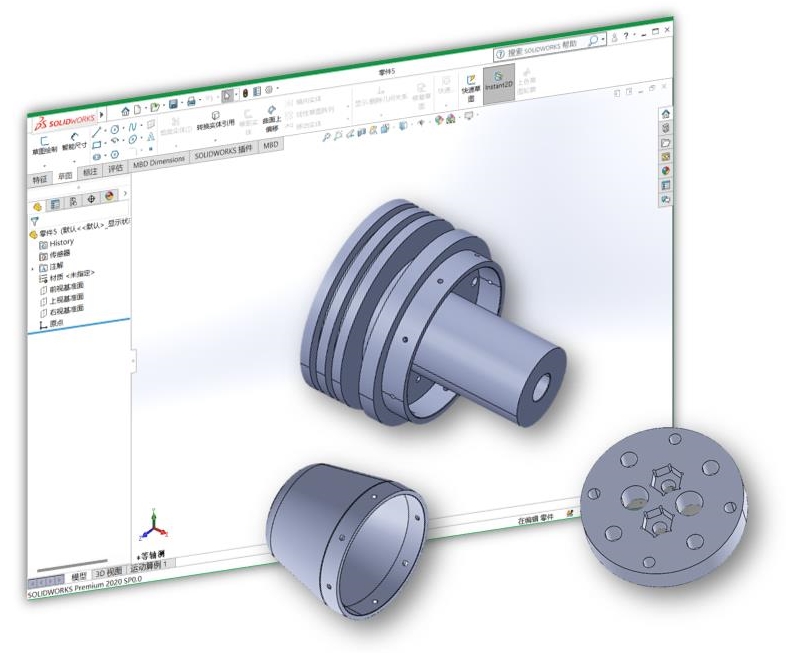

Great Ceramic provides highly customized advanced ceramic components. These technical ceramics offer unmatched wear resistance, thermal stability, chemical inertness, and electrical insulation, delivering industry-leading performance, durability, and precision to mechanical equipment.

Why Advanced Ceramics Matter in Industrial Machinery

Advanced ceramics are inorganic, non-metallic materials that are engineered for mechanical, thermal, chemical, and electrical performance. Their exceptional properties make them ideal for modern machinery operating under severe stress, friction, and temperature fluctuations. These properties reduce machine downtime, extend service life and improve energy efficiency, making technical ceramics widely used in precision engineering and heavy industry.

Advantages Over Traditional Materials

| Property | Advanced Ceramics | Metals | Polymers |

|---|---|---|---|

| Hardness | ★★★★★ | ★★ | ★ |

| Corrosion Resistance | ★★★★★ | ★★ | ★★★ |

| Temperature Resistance | ★★★★★ | ★★ | ★ |

| Wear Resistance | ★★★★★ | ★★ | ★ |

| Electrical Insulation | ★★★★★ | ★ | ★★★ |

| Thermal Conductivity (AlN/BeO) | ★★★★★ | ★★★★ | ★ |

Key Benefits of Using Advanced Ceramics in Industrial Machinery:

Main advanced ceramic materials

At Great Ceramic, we help our customers achieve unprecedented levels of performance, reliability and sustainability by offering a wide range of advanced ceramics with exceptional properties.

| Ceramic Material | Properties & Advantages | Typical Applications (Mechanical Equipment) |

|---|---|---|

| Alumina (Al₂O₃) | High hardness, wear resistance, chemical stability | Mechanical seals, wear-resistant bushings, guide rails, valve components |

| Zirconia (ZrO₂) | High toughness, impact resistance, excellent surface finish | Pump shafts, sleeves, wear rings, precision sliding components |

| Silicon Carbide (SiC) | Extreme hardness, excellent thermal and corrosion resistance | Mechanical seal faces, heat exchangers, nozzles, precision rollers |

| Silicon Nitride (Si₃N₄) | Lightweight, high strength, thermal shock resistance | Ball bearings, turbocharger rotors, spindle components, wear plates |

| Aluminum Nitride (AlN) | High thermal conductivity, electrical insulation | Heat dissipation units in motors, high-frequency insulators |

| Boron Nitride (BN) | Solid lubrication, chemical inertness, thermal stability | Dry bearings, high-temperature lubrication parts, insulative pads |

| ZTA (Zirconia Toughened Alumina) | Tough and hard, enhanced wear resistance | Cutting tool supports, plunger parts, wear-resistant guide components |

| MGC (Machinable Glass Ceramic) | Easy to machine, excellent dielectric and thermal insulation | Precision mechanical parts, custom brackets, electrical insulators |

Key Applications

Great Ceramic's Capabilities

At Great Ceramic, we specialize in the custom machining of advanced ceramic components. Our precision manufacturing services ensure that each part meets exact design specifications with tight tolerances and smooth finishes. We offer:

Relevant Products

Frequently Asked Questions (FAQ)

Why Choose Great Ceramic for Applications?

Whether you're optimizing your production line or developing next-generation equipment, Great Ceramic is your trusted partner in delivering high-performance ceramic solutions.