Applications of Advanced Ceramics in General Manufacturing

In the evolving landscape of modern manufacturing, advanced ceramics are rapidly gaining recognition as essential materials due to their exceptional mechanical strength, thermal resistance, chemical stability, and electrical insulation properties. Unlike traditional ceramics, these engineered materials—also known as technical ceramics or engineered ceramics—are designed to meet the high-performance demands of today's industrial sectors.

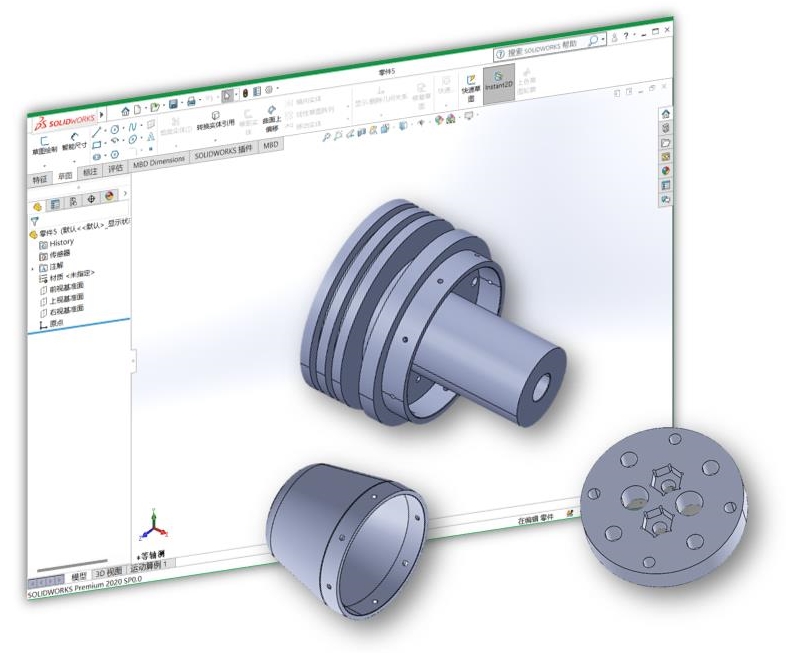

Great Ceramic provides precision-engineered ceramic components designed for general manufacturing. These technical ceramics offer unmatched wear resistance, thermal stability, chemical inertness, and electrical insulation, making them essential for upstream, midstream, and downstream applications.

Why Advanced Ceramics Are Transforming Manufacturing

Advanced ceramics outperform metals and polymers in many applications thanks to their:

Advantages Over Traditional Materials

| Property | Advanced Ceramics | Metals | Polymers |

|---|---|---|---|

| Hardness | ★★★★★ | ★★ | ★ |

| Corrosion Resistance | ★★★★★ | ★★ | ★★★ |

| Temperature Resistance | ★★★★★ | ★★ | ★ |

| Wear Resistance | ★★★★★ | ★★ | ★ |

| Electrical Insulation | ★★★★★ | ★ | ★★★ |

| Thermal Conductivity (AlN/BeO) | ★★★★★ | ★★★★ | ★ |

Main advanced ceramic materials

At Great Ceramics, we help our customers in the general manufacturing industry achieve unprecedented levels of performance, reliability, and sustainability by offering a wide range of advanced ceramics with exceptional performance.

| Ceramic Material | Properties & Advantages | Typical Applications (General Manufacturing) |

|---|---|---|

| Alumina (Al₂O₃) | High hardness, good wear and chemical resistance, cost-effective | Jigs and fixtures, sandblasting nozzles, pipe liners, cutting tool bases |

| Zirconia (ZrO₂) | Excellent toughness, impact resistance, and wear resistance | Precision gauges, stamping dies, locating pins, wear-resistant plates |

| Silicon Carbide (SiC) | Extremely hard, excellent corrosion and thermal conductivity | Grinding wheels, mechanical seals, high-temperature components, liners |

| Silicon Nitride (Si₃N₄) | Lightweight, high strength, good thermal shock resistance | Bearing balls, welding jigs, machine tool insulators, high-temp holders |

| Aluminum Nitride (AlN) | High thermal conductivity, electrical insulation, thermal expansion matched to silicon | Heat spreaders, laser welding jigs, power module substrates |

| Boron Nitride (BN) | Chemically inert, high-temp resistance, lubricating and insulating | Mold release sheets, high-temp gaskets, casting aids |

| ZTA (Zirconia Toughened Alumina) | Balanced toughness and strength, improved wear performance | Precision structural parts, impact-resistant components, seals |

| MGC (Machinable Glass Ceramic) | Easy to machine, excellent insulation and low thermal expansion | Precision jigs, electronic component holders, lab fixtures |

Key Applications

Great Ceramic's Capabilities

At Great Ceramic, we specialize in the custom machining of advanced ceramic components. Our precision manufacturing services ensure that each part meets exact design specifications with tight tolerances and smooth finishes. We offer:

Relevant Products

Frequently Asked Questions (FAQ)

Why Choose Great Ceramic for Applications?

Whether you're optimizing your production line or developing next-generation equipment, Great Ceramic is your trusted partner in delivering high-performance ceramic solutions.